High Capacity Oil Free Scroll Vacuum Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Oil Free Scroll Vacuum Pumps

1.Structure of Oil Free Scroll Vacuum Pump

single stage rotary vane vacuum pumps combining with many years of experience in vacuum engineering and the latest international vacuum technology developed to meet requirements of both the industry and the environment.They are being used in all areas of vacuum engineering. They are equally suited for both industrial production and research applications. They may be used to generate a rough and medium vacuum or as backing pumps in pump combinations with Roots pumps or high vacuum pumps. The comprehensive range (pumping speeds ranging from 10 to 630 m 3 / h) allows every customer to select the right pump for his particular needs.

2.Main features of Oil Free Scroll Vacuum Pump

• Long life design

• The comprehensive range from 10 to 630 m 3 / h

• Vacuum pump entirely replace the pumps like U3/U4,R5,VC,EU and etc.

• High pumping speed also at low pressures

• Optimum price-to-performance ratio

• Low noise level

• Low vibrations

• Integrated exhaust filter, up to 99.9% efficient

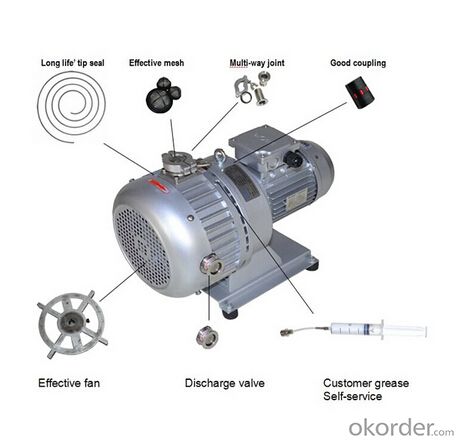

3.Oil Free Scroll Pump Images

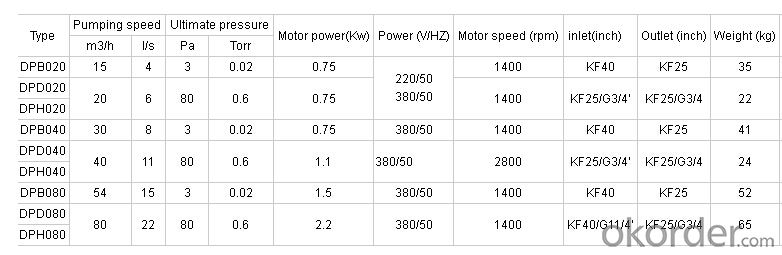

4.Oil Free Scroll Vacuum Pump Specification

5.FAQ

①Application

Food industry , Vacuum packaging, Material drying, Car industry , Furnaces and plants , chemical, Laser technology , Medicinal technology , Metallurgy , Power engineering , Space simulation , Vacuum coating , vacuum loading, electronics, semiconductor, scientific research

- Q: Troubleshooting of diaphragm pump

- The ratio of flow to water weight at a specific weight of --68F. 68F water has a specific gravity of 1Static suction head - the vertical distance from the liquid level to the central line of the pump. The pump shall be above the level of the liquid.Vapor pressure the pressure of all the steam on the free surface of the liquid. In any pump operating system, the operating pressure shall not be lower than the vapor pressure, otherwise the steam will be partially or completely cut off into the pump fluid. Viscosity - because of the presence of friction in the fluid, the property of viscosity gives the fluid resistance to flow.Water hammer action -Water hammer is a sudden power failure, or in the valve closed too fast, due to pressure, flow of inertia, produce water shock waves, like hammer hammer, so called water hammer. The force produced by the flow of water shock waves can sometimes be very large, thereby damaging the valves and pumps. Water hammer effect refers to the inside of the water pipe, the pipe wall is smooth, flow freely. When the opening of the valve suddenly closes, the flow of water to the valve and the tube wall, mainly the valve, will produce a pressure. As the pipe wall is smooth, the subsequent water flow in the role of inertia, the fastest reach the maximum and damage, which is the water conservancy "water hammer effect", that is, "positive water hammer.". This factor should be taken into consideration in the construction of water conservancy pipelines. On the contrary, the valve closed in a sudden opening, it will produce water hammer, called negative water hammer, but also a certain destructive power, but not the former big.. Causes and treatment methods of common failures of diaphragm pumps:

- Q: What is the name of the day pump and ground pump? Specific introduction

- PumpGround pumps are used very frequently in many large basements, because they have no boom, so they need to be taken over manually. In addition to the site, for those days to pump the high-rise buildings, such as 200 meters or 200 meters altitude, can also take over to transport concrete by pump, but the premise is to have enough power to pump concrete will hit above the height and the length of nozzle can reach the height of the floor.Thus, the day pump and ground pump have their respective advantages. The pump is easy to use, but the ground pump can make up for the height that the pump can not reach. At the same time, the price is relatively cheap, so users can choose the corresponding concrete pump when they are in use.

- Q: What are the important parameters of the pump?

- Pump parametersFlow rate QFlow is the amount of liquid (volume or mass) that is pumped out in unit timeVolume flow is expressed in Q units: m3/s, m3/h, l/s, etc.

- Q: What should I pay attention to when buying a pump?

- Two, the first choice of large and medium-sized professional manufacturers, and through the quality identification of relevant departments, the market credibility of the better models, but also to the professional quality inspection institutions consultation.Three, check the motor grounding device for electric pump, water pump and motor axis, the motor should be in a proper position is provided with a grounding screw, and the grounding screw are arranged near the ground; grounding device of small submersible pump should be reliable and grounding wire, grounding wire cables should have the obvious grounding mark the flag should be in use; the motor is not easy to be worn during the period. This is one of the important safety indexes of electric pumps.

- Q: What is the lift off the dead center point? This is a straight mark about the water pump. What is the function and the relationship between the design head and the pump head? ThanksWhat exactly is the dead point lift? What's the function of this indicator?

- The dead point head is the measured head after the outlet valve is closed. Mainly on the lower reaches of the pump equipment, such as your dead center, the lift is 300 meters, that is, 3MPa

- Q: Operating procedures for measuring pumps

- start-up1. Adjust the stroke indication to zero by adjusting the nut or handle with the rotary stroke.2 open the outlet valve.3. Open the inlet valve, pump, exhaust from the high point, exhaust from the relief valve, the breather valve.4, point motor, check the operation of the pump.5. Start the motor.6, without pressure on the premise, every 15 minutes to improve the stroke 20%, if there is no pressure, do not substantially improve the stroke.Note: (1) whether the sound or vibration of the pump is abnormal (2), whether the stroke adjustment is automatic or not

- Q: Is the flow meter in front of the pump or after the pump?

- Agree upstairs. Pump should be straight before the paragraph, 15 times the nominal length of the caliber.

- Q: How many square cables does the submersible pump for 7.5KW need?

- I=P/ (1.732Ucos phi) =7.5/ (1.732X0.38X0.85) =13A (calculated according to three-phase city power, power factor 0.85).

- Q: What is a vacuum pump for?

- Aquaculture, screen printing machine, photographic plate machine, injection molding machine, automatic feeding machine, paper transport...

- Q: Do you have a suction pump higher than 9 meters?

- Since the atmospheric pressure has been basically determined, the theoretical suction degree of the pump is more than 10 meters.

Send your message to us

High Capacity Oil Free Scroll Vacuum Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords