High Quality Oil Free Dry Scroll Vacuum Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Oil Free Scroll Vacuum Pumps

1.Structure of Oil Free Scroll Vacuum Pump

single stage rotary vane vacuum pumps combining with many years of experience in vacuum engineering and the latest international vacuum technology developed to meet requirements of both the industry and the environment.They are being used in all areas of vacuum engineering. They are equally suited for both industrial production and research applications. They may be used to generate a rough and medium vacuum or as backing pumps in pump combinations with Roots pumps or high vacuum pumps. The comprehensive range (pumping speeds ranging from 10 to 630 m 3 / h) allows every customer to select the right pump for his particular needs.

2.Main features of Oil Free Scroll Vacuum Pump

• Long life design

• The comprehensive range from 10 to 630 m 3 / h

• Vacuum pump entirely replace the pumps like U3/U4,R5,VC,EU and etc.

• High pumping speed also at low pressures

• Optimum price-to-performance ratio

• Low noise level

• Low vibrations

• Integrated exhaust filter, up to 99.9% efficient

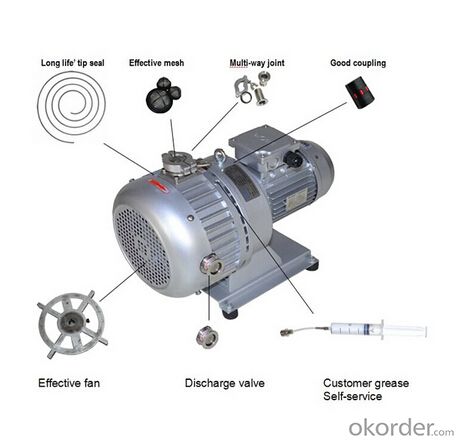

3.Oil Free Scroll Pump Images

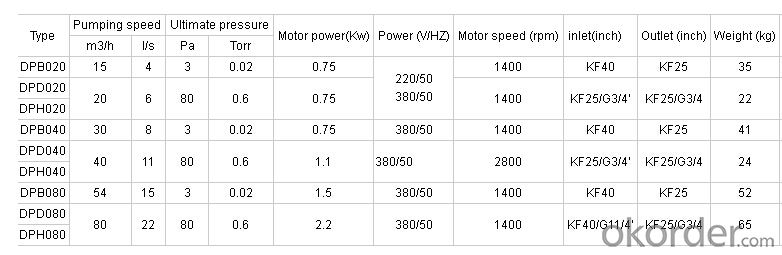

4.Oil Free Scroll Vacuum Pump Specification

5.FAQ

①Application

Food industry , Vacuum packaging, Material drying, Car industry , Furnaces and plants , chemical, Laser technology , Medicinal technology , Metallurgy , Power engineering , Space simulation , Vacuum coating , vacuum loading, electronics, semiconductor, scientific research

- Q: How to adjust the flow of piston pump?

- Changing the size of the current in the solenoid valve can change the angle of the tilting element, and then change the stroke length of the plunger in the pump cylinder, that is to say, to change the flow of the pump. An inclined angle is called a quantitative pump, and the angle of inclination can be changed, which is called a variable pump.

- Q: What is a water pump coupling device?

- The automatic coupling device of the water pump coupling device has compact structure and small occupation area. The sump pump works because it is submergedThe utility model can be directly installed in a sewage pool, and no special pump house is needed to install a pump and a machine, thereby saving large amounts of land and infrastructure expenses

- Q: What are the important parameters of the pump?

- Pump parametersFlow rate QFlow is the amount of liquid (volume or mass) that is pumped out in unit timeVolume flow is expressed in Q units: m3/s, m3/h, l/s, etc.

- Q: Variable flow pumps are variable pumps

- Variable input speed, the pump out of the flow is variable, it can not be said that it is variable pump.In a word。 A variable pump is a variable displacement pump.

- Q: Water pump outlet valve sequence

- To reduce the impact of vibration, noise and vibration on the valve, the soft connection is best at the pump outlet.The check valve is sometimes checked, so it is placed in front of the outlet valve so that the water can be checked out. I think the order should be: pump outlet, soft connection, check valve, gate valve (butterfly valve)

- Q: What is the lift of diaphragm pump?

- Tell you: diaphragm pump head is liquid through the pump energy obtained is called lift it, and flow and pump speed, a liquid density is generally 1 kg is 10 meters lift, horizontal pipeline 10 meters 1 meters lift, a 90 degree bend is 1 meters.

- Q: Rules for operation of centrifugal pumps

- 5, before you stop, you should gradually close the outlet valve, then turn off the power supply.6, with the check valve line, in ensuring the check valve intact, without closing the outlet valve, check the pump cavity, no air can be directly switched on.

- Q: Direct connection pump What is straight pump and non direct pump? What's the difference in structure?

- What is straight pump and non direct pump? Direct coupled pump shaft and the motor shaft is directly coupled with the coupling and non direct coupled pump: pump shaft and motor shaft through the belt pulley, V-belt connection or other forms of transmission. What is the difference in the structure: the direct coupled pump has the advantages of compact structure, simple installation, but the relatively small power; non direct coupled pump: pump and motor is independent, the two transfer torque through the belt, the structure is relatively large, complex installation, general power is relatively large.

- Q: How accurate is the metering pump?

- The measuring accuracy of the stable metering pump is as follows:In a diaphragm metering pump, the reciprocating motion of the plunger is passed to the diaphragm through the hydraulic chamber between the plunger and the diaphragm. In order to maintain the normal movement of the diaphragm, the hydraulic chamber is required to keep the volume of the liquid in the space (usually using hydraulic oil) unchanged. In order to ensure that the volume of the formation of membrane movement is always equal to the stroke volume of the plunger pump, so as to maintain the stability of the flow, but in the actual operation of the pump, the plunger seal will inevitably cause leakage at the same time, there may be a gas into the hydraulic chamber

- Q: Why does the centrifugal pump start with a closed valve and the axial pump starts with an opening valve?

- Centrifugal pumps require a vacuum to produce negative pressure, which allows atmospheric pressure to lift the water surfaceAxial flow pump impeller is thrust on water

Send your message to us

High Quality Oil Free Dry Scroll Vacuum Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords