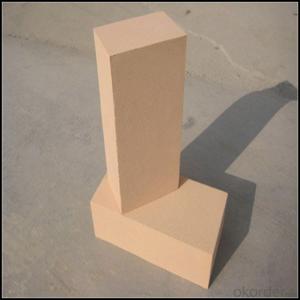

High Alumina Insulating Fire Bricks for High Temperature Working

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Brick

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay by mixing, press-forming, drying, sintering and machining. Bricks contain carefully-graded organic fillers which are burned out during sintering to give a uniform controllable pore structure. This technique makes product feature low thermal conductivity and excellent heat insulation

Advantages of high alumina brick

1 Excellent thermal stability

2 High refractoriness under load

3 Chemical stability and anti-corrision

4 Small high temperature creep rate

5 Excellent thermal shock resistance

Characteristices of high alumina brick

1.High intensity for pressure

2. Good thermal shock stability

3. Strong abrasion and corrosion resistance

4. High cold crushing strength

5. Excellent abrasion resistance at cold and hot conditions

Application

1. Furnaces of metallurgy industry, heat treatment furnace

2. Furnaces of chemical industry and construction industry.

3. Furnace of incineration of garbage, recirculating fluidized bed furnace

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: What are the safety precautions when working with insulating fire bricks?

- To ensure the safety of yourself and others when working with insulating fire bricks, it is crucial to follow various safety measures. Consider the following key precautions: 1. Personal protective equipment (PPE): Protect yourself by wearing suitable PPE, such as heat-resistant gloves, long-sleeved clothing, safety goggles, and a respiratory mask. These items will safeguard you against potential burns, cuts, and the inhalation of harmful dust or fumes. 2. Adequate ventilation: Work in a well-ventilated area or utilize local exhaust ventilation to minimize exposure to dust and fumes that may be released during the handling or cutting of the bricks. 3. Fire prevention: Keep a fire extinguisher close by and ensure that the workspace is free of flammable materials. Although insulating fire bricks are highly refractory and can withstand high temperatures, it is still crucial to prevent accidental fires. 4. Proper lifting techniques: As insulating fire bricks can be heavy, employ correct lifting techniques and avoid overexertion to prevent strains or injuries. If necessary, use mechanical aids like trolleys or lifting equipment to move the bricks. 5. Cutting and grinding: Utilize appropriate tools in good working condition when cutting or grinding the bricks. This will minimize the risk of accidents or injuries. Pay attention to sharp edges and wear protective gloves to prevent cuts. 6. Temperature control: While insulating fire bricks are designed to handle high temperatures, avoid direct contact with hot surfaces. Use suitable tools or equipment to handle the bricks when they are at an elevated temperature. 7. Storage and handling: Store the bricks in a cool, dry place away from direct sunlight or extreme temperatures. Avoid stacking them too high to mitigate the risk of collapse or toppling. 8. Training and knowledge: Ensure that you have undergone proper training and are familiar with the characteristics and properties of insulating fire bricks. Understand their limitations and adhere to the manufacturer's guidelines for safe handling and usage. By adhering to these safety precautions, you can significantly decrease the likelihood of accidents, injuries, and health hazards when working with insulating fire bricks. Always prioritize safety in any workplace.

- Q: Are insulating fire bricks suitable for outdoor applications?

- No, insulating fire bricks are not suitable for outdoor applications as they are not designed to withstand the harsh weather conditions and exposure to moisture.

- Q: Can insulating fire bricks be used for insulation in flues?

- Yes, insulating fire bricks can be used for insulation in flues. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for lining and insulating flue systems. They help to prevent heat loss, improve energy efficiency, and enhance the overall performance of the flue.

- Q: Can insulating fire bricks be used to line industrial boilers?

- Yes, insulating fire bricks can be used to line industrial boilers. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties. They are commonly used in industrial applications, including lining furnaces, kilns, and boilers, to reduce heat loss and improve energy efficiency.

- Q: Coke burns in a closed house. Will anyone suffocate in it?

- Coke combustion, can produce carbon dioxide gas released into the atmosphere can increase the concentration of carbon dioxide in the atmosphere, the greenhouse effect is getting worse, a series of harmful to human disasters occur more frequently. And too much carbon dioxide inhalation can cause hypoxia, inhibition of the respiratory system, causing death.

- Q: Can insulating fire bricks be used in the construction of autoclaves?

- Yes, insulating fire bricks can be used in the construction of autoclaves. Autoclaves require materials that can withstand high temperatures and pressures, and insulating fire bricks are designed to have excellent thermal resistance and insulation properties. These bricks are made from refractory materials like alumina, silica, and other additives that allow them to withstand extreme temperatures and thermal shocks. They are also lightweight and have low thermal conductivity, which helps to minimize heat loss and improve energy efficiency in autoclaves. Additionally, insulating fire bricks have good load-bearing capacity, making them suitable for the structural components of autoclaves. Overall, the use of insulating fire bricks in the construction of autoclaves helps to ensure the safety and efficiency of the equipment.

- Q: Can insulating fire bricks be used in the construction of incinerators?

- Indeed, insulating fire bricks are applicable for utilization in the construction of incinerators. The paramount significance lies in the exceptional thermal insulation properties possessed by these bricks, which play a vital role in sustaining elevated temperatures and enhancing energy efficiency within the incinerator. The bricks' low thermal conductivity enables them to proficiently retain heat and curtail heat loss. Moreover, their resistance to high temperatures enables them to endure the intense heat generated by the incineration process. Consequently, these bricks emerge as an appropriate preference for lining the walls, floors, and roofs of incinerator chambers, thereby ensuring the incinerator's efficient and secure operation.

- Q: Can insulating fire bricks be used in glass furnaces?

- Yes, insulating fire bricks can be used in glass furnaces. They are commonly used to line the walls and roofs of glass furnaces to reduce heat loss, improve energy efficiency, and provide thermal insulation.

- Q: Can insulating fire bricks be used in hydrogen furnaces?

- Yes, insulating fire bricks can be used in hydrogen furnaces. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in hydrogen furnaces where extreme heat is involved.

- Q: Are insulating fire bricks resistant to thermal radiation?

- Yes, insulating fire bricks are resistant to thermal radiation. These bricks are specifically designed to have excellent thermal insulation properties, which means they can effectively resist and minimize the transfer of heat by radiation. Insulating fire bricks are typically made from materials such as alumina, silica, or fire clay, which have high melting points and low thermal conductivity. This combination of properties allows them to withstand high temperatures and prevent the flow of thermal energy through radiation, making them a suitable choice for applications where thermal insulation is required, such as kilns, furnaces, and fireplaces.

Send your message to us

High Alumina Insulating Fire Bricks for High Temperature Working

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords