High Alumina Brick - High Quality Best Price Insulated Refractory Fire Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shaanxi, China (Mainland) | Shape: | Brick | Material: | Alumina Cement |

| SiO2 Content (%): | 0.1~1.4% | Al2O3 Content (%): | 48%-85% | MgO Content (%): | 0.1~1.4% |

| CaO Content (%): | 0.01 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.1~0.3% |

| SiC Content (%): | 0.1~1.4% | Model Number: | DFL-LZ | Brand Name: | CNBM |

| size: | LZ-85, 80, 70, 65, 55, 48 | apparent porosity: | 23% Max | refractoriness: | 1750℃ Min |

| refractoriness under load: | 1420℃ Min | cold crashing strength: | 35 MPa Min | Al2O3: | 48% Min |

| thermal shock resistence: | 4-10 | reheating linear change: | 1450℃x2 +0.1 -0.4 | experience: | over than 15 years |

| quality system: | ISO9001-2008 |

Packaging & Delivery

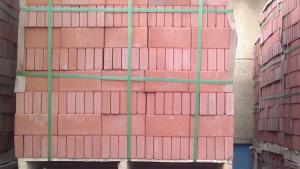

| Packaging Details: | in pallet for sea ship |

| Delivery Detail: | 15-45 days after get customers's deposit |

High alumina bricks

description

Specifications of high alumina bricks

1. AL2O3 : 45%-80%.

2. Can according to customers' requirements.

3. Used for steel ladle lining.

High alumina steel ladle fire brick,Steel ladle brick,Ladle brick

Application of high alumina bricks

High alumina brick is widely used for Widely used in blast furnaces, Hot Blast Stove, Steel ladle lining, Reheating furnace, Cement kiln,Tunnel kiln,boiler, coke oven, carbon furnace,glass kiln , Steel smelting furnace and various kiln lining and thermal technical equipment, etc.

Features of high alumina bricks

1) High-temperature endurable .

2) Good thermal shock resistance .

3) Good resistance to abrasion and corrosion.

4) Good thermal shock and thermal spalling resistance.

5) High mechanical strength.

6) Good volume stability at high temperature.

Physical and chemical index of high alumina bricks

Item | Specification | ||||||

LZ-85 | LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

Al2O3 | 85 | 80 | 75 | 65 | 55 | 48 | |

Apparent density | 23 | 22 | 23 | 23 | 22 | 22 | |

Cold crushing strength | 65 | 55 | 50 | 45 | 40 | 35 | |

RUL | 1600 | 1530 | 1520 | 1500 | 1450 | 1420 | |

PLC | 1500.C*2h | 0.1~-0.4 | |||||

1450.C*2h | 0.1~-0.4 | ||||||

Standards of Type Brick:

| 230mmx114mmx65mm

Product Range: SK32,SK34,SK35,SK36,SK37,SK38

| ||||||

Specail Shape of High Alumina Brick

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- From the year 2015 to the year 16 the end of the year, refractories industry presents two kinds of situations: one is a small business, a single product variety and equipment, to meet the demands of both environmental protection and the downstream market, such enterprises are generally in the Qing state inventory;

- Q: How are the high alumina bricks fired?

- According to the quality requirements of different grades of high alumina brick, choose different grades of bauxite raw materials, it is conducive to rational use, fine materials, fine distribution, as far as possible not to use mixed grade severe raw materials. The quality of the clinker depends on the calcination temperature, calcination temperature, sintering temperature should be generally reached or slightly higher than that of alumina clinker sintering, to ensure the full and possible high volume density, and the two secondary Mullitization and sintering shrinkage effect in calcination process. Lightweight high alumina brick, also known as high aluminum insulation brick (high-aluminium heat insulating brick). A lightweight refractory consisting of mullite and glass phases or corundum in excess of 48%. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- Lining 1 yuan to prevent direct damage to the Sindh kiln high temperature flame or air, to protect the kiln carcass; 2, to prevent harmful substances (CO, SO2) erosion of the kiln body; 3, to prevent corrosion, material flow on the kiln body; 4, reduce the kiln temperature, kiln body to prevent oxidation 5, has the function of corrosion; thermal insulation; 6, to improve the coating performance.

- Q: What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- The question is good, these two belong to the high aluminum brick products, when many manufacturers buy, I do not know how to distinguish.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Forming high alumina brick will be tested on some professional equipment, it is suggested that you can go to the professional testing department to know about it!

- Q: What kind of material is the general metal case?

- Ordinary computer chassis and the material itself does not produce high-energy radiation, only in the space environment of the computer is the external defense requirements, and in the space structure, the use of lead as protective materials, unbearable weight.

- Q: Is glass wool inorganic thermal insulation material?

- The characteristics of glass wool, glass wool is the molten glass fibrosis, the formation of cotton like material, chemical composition of glass, is a kind of inorganic fibers. With good forming, small volume density, thermal conductivity, both thermal insulation, sound-absorbing performance, corrosion resistance, chemical stability.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The physical and chemical properties of refractory materials used in rotary kiln are as follows: physical and chemical properties of refractory materials used in rotary kilnMaterial name: high temperature compressive strength (MPa), softening temperature (DEG C), thermal shock resistance (1100 DEG C, cold water), sub volume density (g/cm3)Magnesia spinel brick is greater than or equal to 50 is greater than or equal to 1700 = 12 = 2.95High alumina brick is greater than or equal to 75 = 1520 = 8 = 2.57High aluminum bricks more than 50 = 1700 = 12 = 1The clay brick is greater than or equal to 30 = 1400 = 12 = 2.30

- Q: What are the categories of bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

Send your message to us

High Alumina Brick - High Quality Best Price Insulated Refractory Fire Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords