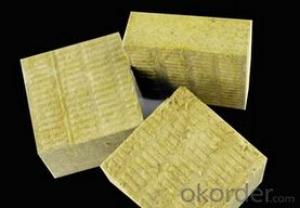

Ceramic Fiber Board - Fireproof Rock Wool Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Grade A1 incombustible materials.

Easy for construction; Cutting at will.

Antisepsis, ageing resistance, and anticorrosion,

Distinctive advantages:

Unique technology; Rebound degree after compressive packing is up to 99.2%.

Soft and long glass fibers can maximally lessen flying catkins in the construction.

Sound absorption and noise reduction; It can effectively prevent sound from spreading.

Grade A1 incombustible materials.

Easy for construction; Cutting at will.

Antisepsis, ageing resistance, and anticorrosion, ensuring a healthy environment.

Low moisture absorption; Stable physical properties.

Scope of application:

It is widely used for heat insulation and sound absorption in industrial workshops, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc.

Technical Parameters item unit index measured value remarks

Bulk density kg/m3 10-96 10-96 GB/T 13350-2000

Average diameter of fibers m < 8.0 4.0-6.0 GB/T 13350-2000

Moisture resistivity % > 98 > 98.5 JISA9512-2000

Thermal conductivity W/m. K 0.049-0.042 0.045-0.032 GB/T 13350-2000

Incombustibility incombustible up to standard (Grade A) GB/T 13350-2000

Sound absorption coefficient 1.03product reverberation positioning 24kg/m3 2000Hz GB/J47-83

Max. Working temperature 400 410 GB/T 13350-2000

Product | Length(mm) | Width(Diameter)(mm) | Thickness(mm) | Density(kg/m3) | Notice |

Blanket (felt) | 3000-5000 | 200-900 | 30-80 | 80-150 | |

Boards (Slab) | 1000-1200 | 600-1200 | 50-100 | 80-200 | |

Pipe Sections | 1000 | 18-630 | 30-150 | 60-150 |

Rock Wool Technical Parameters:

| Item | unit | index | experimental method |

density | Kg/m3 | 50-200kg/m3 | GB5480.3 |

density allowable deviation | % | ± 10 | |

average value of fiber | um | 4-7 | GB5480.4 |

slag ball content (granule diameter)> 0.25mm) | % | 6 | GB5480.5 |

volume water absorption | % | 2 | GB/GB16401-1996 |

heat absorption | % | 1.0 | GB5480.7 |

moisture resistivity | % | 98 | B10299-88 |

shrinkage temperature of heat load | 650 | GB11835-1998 | |

organic content | % | 4% | GB11835-1998 |

compressive strength (10% compressibility) | kPa | 40 | GB/T13480-92 |

peeling strength | kPa | 14 | DIN52274 |

incombustibility | -- | Grade A | GB5465 |

thermal conductivity (70 ) | W/mk | 0.036~0.048 | GB10294-88 |

acidity coefficient | 1.5 | ||

binder content | % | 3.0 |

FACTORY:

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Volume density is low: the density of the ceramic fiber lining is about 25% of the lining of the light heat insulation brick, about 10% of the lining of the light pouring material; adopting the fiber lining can greatly reduce the steel structure load of the furnace and prolong the service life of the furnace lining.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- Ordinary materials have sound-absorbing effect, just how much difference. And when it comes to sound-absorbing board, we are only sound-absorbing coefficient of more than 0.3 of the material known as sound-absorbing material.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: What are the uses of ceramic fiber boards?

- According to the conditions of use, can be divided into:Fire dragon high purity ceramic fiber fire block HLGX-364DThe dragon high alumina ceramic fiber fireproof plate HLGX-464D

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Ceramic fiber board is aluminum silicate fiber board, a refractory material. Even after heating, good mechanical strength is maintained. The product is a fibrous insulation product that is rigid and has a supporting strength compared to fiber blankets. Features: ceramic fiber board has excellent quality, toughness and strength, besides, it has excellent resistance to wind erosion. The utility model has the advantages of no heat expansion, light weight, convenient construction, and arbitrary shearing and bending. The utility model is an ideal energy-saving material for kilns, pipes and other heat preservation equipment.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board divided by density, can be divided into ceramic fiber, ceramic fiber board density 250-260Kg/m fand; density, fand 300-350Kg/m;

Send your message to us

Ceramic Fiber Board - Fireproof Rock Wool Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords