HDPE Drainage Geonet used in Construction Earthwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

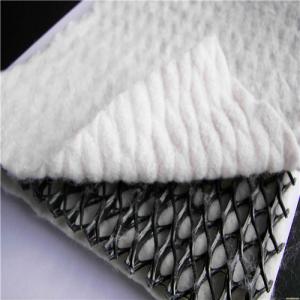

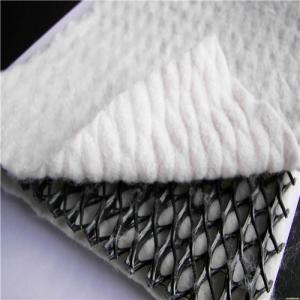

Composite Geonet Description:

Composite geonet is a new type drainage material. It has three layers: three-dimensional geonet and nonwoven geotextile on both sides.

The material of geonet is HDPE, and the material of geotextile can be needle punched PET/PP nonwoven geotextile, and thermalbonded continuous filament nonwoven geotextile.

Composite Geonet Specification:

Thickness of geonet: 5mm to 8mm

Weight of geotextile: 200g/m2, as request

Width: 2m-4m

Length: as request

Composite Geonet Application:

Landfill drainage, roadbed and road drainage, railway drainage, tunnel drainage, underground

structure drainage, the retaining back wall

drainage, gardens and sports grounds drainage.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

4.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

5.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

6.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

7.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: Can earthwork products be used in stormwater management systems?

- Yes, earthwork products can be used in stormwater management systems. These products, such as retaining walls, berms, and swales, help control and direct the flow of stormwater, prevent erosion, and filter pollutants before they reach water bodies.

- Q: What are the benefits of using geocells in erosion control projects?

- One of the main benefits of using geocells in erosion control projects is their ability to provide structural support and stability to the soil. Geocells are typically made of high-density polyethylene and are filled with soil or aggregate material. When placed on slopes or along riverbanks, they prevent erosion by confining the fill material and increasing its resistance to movement. Additionally, geocells allow for vegetation growth, reinforcing the natural ecosystem while minimizing the environmental impact of erosion control measures.

- Q: How do geosynthetic liners prevent seepage in wastewater treatment plants?

- Geosynthetic liners prevent seepage in wastewater treatment plants by acting as a barrier between the wastewater and the surrounding soil. These liners are made of impermeable materials that do not allow water to pass through, thus preventing any potential contamination of the soil or groundwater.

- Q: Can earthwork products be used for constructing athletic fields?

- Yes, earthwork products can be used for constructing athletic fields. Earthwork products such as soil, gravel, and aggregates are commonly used in the construction of athletic fields to provide a stable and level playing surface. These materials are used for grading, leveling, and adding drainage capabilities to the field. Additionally, earthwork products can also be used for constructing retaining walls, berms, and other necessary structures within the athletic field.

- Q: How can geocomposites be used in subsurface irrigation systems?

- Geocomposites can be used in subsurface irrigation systems by serving as a protective layer that prevents clogging of the irrigation pipes. They also aid in water distribution and filtration, improving the efficiency of the irrigation system. Additionally, geocomposites can help with soil moisture control and reduce water wastage, making them a valuable component in subsurface irrigation systems.

- Q: What is the purpose of earthwork products?

- The purpose of earthwork products is to provide solutions for various construction and landscaping projects that require excavation, grading, and shaping of the earth. These products, such as geotextiles, geogrids, and erosion control materials, are used to stabilize soil, prevent erosion, reinforce foundations, and enhance drainage systems, ensuring the durability and longevity of structures and landscapes.

- Q: How do earthwork products contribute to slope stability?

- Earthwork products, such as geotextiles and geogrids, play a crucial role in enhancing slope stability. These products are used to reinforce and stabilize the soil in a slope, preventing erosion and reducing the risk of slope failure. Geotextiles are permeable fabrics that are placed between soil layers to improve their strength and prevent soil particles from getting washed away by water. Geogrids, on the other hand, are mesh-like structures that provide tensile strength to the soil, increasing its resistance to shearing and sliding. By reinforcing the soil, earthwork products help maintain the integrity of slopes, ensuring their long-term stability.

- Q: What are the key considerations when using geotextile tubes for shoreline stabilization?

- When using geotextile tubes for shoreline stabilization, there are several key considerations to keep in mind. Firstly, the design and placement of the geotextile tubes should align with the specific requirements and conditions of the shoreline. Factors such as wave energy, sediment composition, and tidal movements should be carefully considered to ensure the effectiveness of the stabilization system. Secondly, the selection of appropriate geotextile materials is crucial. The geotextile tubes should be durable, resistant to UV degradation, and capable of withstanding the forces exerted by waves and currents. The permeability of the geotextile should also be considered to allow for proper water drainage and prevent erosion. Furthermore, proper installation techniques are essential for the success of shoreline stabilization with geotextile tubes. Adequate anchoring and connection methods should be employed to ensure the stability and integrity of the system. Regular monitoring and maintenance are also necessary to address any potential issues and ensure long-term effectiveness. Finally, it is important to consider the environmental impacts of using geotextile tubes for shoreline stabilization. Care should be taken to minimize any potential negative effects on local ecosystems and habitats. Consulting with environmental experts and obtaining necessary permits and approvals may be required to ensure compliance with regulations and guidelines.

- Q: What are the benefits of using geocells for ground stabilization?

- Geocells offer several benefits for ground stabilization. Firstly, they provide effective confinement and lateral support, preventing soil erosion and maintaining the integrity of the ground. Secondly, geocells distribute loads evenly, reducing stress concentration and improving load-bearing capacity. Additionally, they enhance soil compaction, increasing the overall stability of the ground. Geocells are also cost-effective, as they require less material and labor compared to traditional methods. Furthermore, they are environmentally friendly, as they can be made from recycled materials and promote vegetation growth. Overall, geocells offer a sustainable and efficient solution for ground stabilization in various applications.

- Q: Can earthwork products be used for constructing walkways and pathways?

- Yes, earthwork products can be used for constructing walkways and pathways. Earthwork products such as gravel, crushed stone, and sand can be used as base materials for walkways and pathways, providing stability and a solid foundation. Additionally, geotextiles can be used to reinforce the soil and prevent erosion in areas with heavy foot traffic.

Send your message to us

HDPE Drainage Geonet used in Construction Earthwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords