Film Faced Plywood for Concrete Formwork Cheap Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

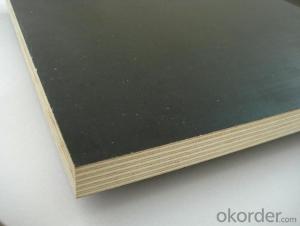

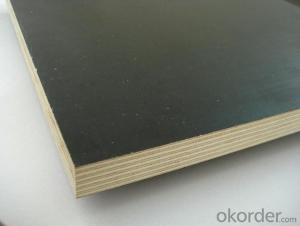

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

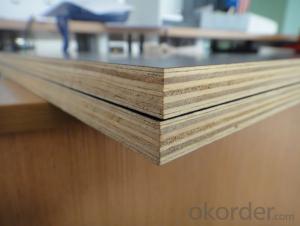

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

Item | Film Faced Plywood | |

Face/back |

black film or brown film,logo available | |

Core Material | poplar,hardwood,combi,finger jointg board,etc. | |

Size(mm) | 1220x2440, 1200x2400, 1250x2500, 1830x915,610x2440,etc. | |

Thickness | 9mm 12mm 15mm 18mm 21mm | |

Grade | One time hot press, two times hot press,three times hot press | |

Length(width) tolerance | 1mm | |

Thickness tolerance | +/-0.5mm or +-1mm | |

Glue | WBP(phenolic), MR, WBP MELAMINE | |

Mositure content | 8%-16% | |

Main market | Saudi Arabia,South America,Africa,Europe, India,Southeast Asia,South Korea,Thailand,etc | |

packing | Inside:pallet is wrapped with 0.2mm plastic bags; outside:pallets are covered with caton paper or plywood ,and then PVC/steel tape for strength | |

Loading quantity | 20GP | 8pallets/20M3 |

40GP | 16pallets/42M3 | |

40HQ | 18pallets/55M3 | |

Usage | Widely used for concrete formwork,shuttering work,construction,truck flooring,etc. | |

Minimum Order | 1*20GP | |

Payment | T/T or L/C at sight | |

Delivery Time |

10-30 days according to order quantity | |

Features

Film faced plywood is a newfashioned materials, which can be used as steel template in construction with the special snap linked. Being characterized by acid-resisting, alkaline-resisting, moisture-resisting and rotproof, it can be easily used from below 20 centigrade to 60 centigrade. Form erecting and removal is very convenient. Above all, film faced plywood can take place of steel template and bamboo raft, not only reducing the cost but saving the consumpution of steel and bamboo.

1. Film is phenolic resin adhesive membrane to make the smooth, low scratched surface and protect the plywood usage.

2. Plywood core is using either Softwood or Hardwood.

3. Plywood includes many layers of veneers that be hot pressed for 2~3 times with water proof(WBP)glue helping to increase elasticity, hardness of plywood and working capability in wet outdoor condition.

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

Products Photos

- Q: What are the allowable quantity differences in printed packaging materials?

- Printing, printing, usually three printing on a flat surface of a substrate. Screen printing can not only be printed on a flat surface, but also printed on a surface, and the spherical surface of the substrate is convex. On the other hand, screen printing is not only printed on hard objects, but also can be printed in a soft material without substrate limitations. In addition, screen printing, in addition to direct printing, can also be used according to the needs of indirect printing process, which is to use silk screen printing in gelatin or silica gel version, and then transferred to the substrate. Therefore, we can say screen printing is adaptable and wide range of applications. Strong, rich, textured layer thickness

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- Roll material, screen printing or rotary printing (relatively few, only for thickness below 0.125MM), printing the same as above.

- Q: Carton printing process and materials

- Single-sided corrugated production line adopts plastic gravure printing process composite paper carton packaging, paper printing also need to be completed if the light coating film, and large volume production, can be printed on the paper, and the way for gravure printing gravure printing on plastic film, and with white plastic film and paper and then the first printed composite, and then complete the box according to the conventional carton forming process.The process is characterized by:(1) the cost of making cartons is low. When the production batch is large, the printing cost and the material cost of the facial tissue can be greatly reduced by the process. Because the paper does not need to be printed, the uncoated white board paper can be used so as to greatly reduce the cost of the facial tissue.(2) beautifully printed. Because the plastic gravure printing is adopted, the printing effect can be compared with the offset printing effect. The process requires special attention. In the process of printing, it is necessary to take full account of the plastic film size changes and deformation; otherwise, the carton paper will be inconsistent with the lower paperboard.

- Q: What are the materials used in screen printing?

- Divided into printed screen and printed material, screen according to different processes are divided into water-based and solvent based, printed material according to different substrate is divided into ink and ink

Send your message to us

Film Faced Plywood for Concrete Formwork Cheap Price

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords