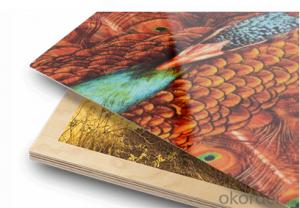

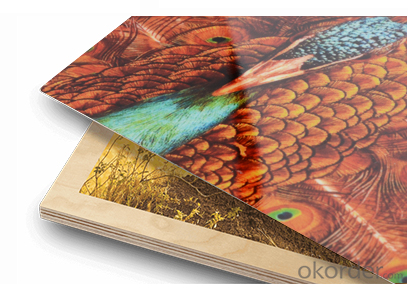

HD Metal Board, HD Aluminium Board, Recommended Sublimation Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Sublimation Coated Aluminium Sheet

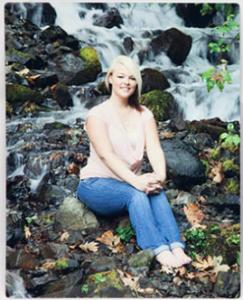

Sublimation aluminium sheet is manufactured specifically for sublimation printing

The hard surface coating on this aluminium is designed for improving image retention

Suggested heat transfer parameter: 200 ℃ and 40 seconds

Safe packaging and film for protection

High quality coating for sublimation and high definition

You can print any logo or pictures on it

Name of the product: Sublimation Coated Aluminium Sheet

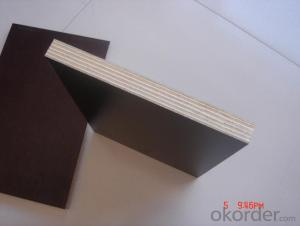

Thickness: 0.45mm,0.55mm, other sizes as your customized

Size: 610*305mm,300*600mm,400*600mm,600*1200mm

Surface finish: Glossy, Matte, Satin, Pure,Pearlized,Brushed,Satin etc

Color: White,Silver,Gold,Cooper,Champange

Protection Film: PE,PVDF,PEVE,UV

Packaging: Seaworthy wooden pallet, wooden case or upon your request

Packaging & Delivery Packaging Details

Seaworthy wooden pallet, wooden case or upon your request

Delivery Detail

15~30 days after deposite

Weight of Packaging

1000 pics per pallet,Around 800 kg

What is WunderBoard HD metal prints?

Wunderboard is high-definition sublimation aluminum:

- Material: Aluminum

- Thickness: 1.14mm (0.045”)

- Biggest size: 1.2x1.2m (different/custom sizes are available)

- Finish: Glossy white

- Coating: 4 layers

--Water-proof, scratch-resistant and anti-UV.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top

4. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

5. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

6. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

7. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

8. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

9. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

10. Enjoy your personal designed aluminum board!

These products are OK:

Sublimation Blanks

Heat press machine

DTG&UV pintor

The free samples are available, we're pleased to offer you some for testing.

- Q: How to make the screen print surface smooth?

- You can use paint thinner on the back (pattern) paint wipe, repeat a few times, and check whether the pattern is transparent.If the number of prints is not large, the back should not be painted.

- Q: Can you tell me how to make a good print?

- Dot reproduction control1, eliminate mesh halo phenomenonTimely maintenance of printer, ensure good working condition of vacuum pump, pumping enough, print, rubber gasket shelf, good sealing effect; print, in recognition of the plate and the original close tightly, can open the light exposure; collage of the original, to repair the original burr on the edge of the adhesive tape to paste. From the image as far as possible, or made of the original and the whole piece of close fit plate.2, eliminate the loss of outletsShould look at the film itself dot degree, such as film on the 50% ideas is founder, 4% ~ 5% outlets are complete, in short, to check the quality of phototypesetting film, and then judge whether the network is lost in the print process. Excessive exposure, too much concentration of the developer, will make the page should retain the loss of points or text strokes thinning. The image density of less than 1.5 of the original, thinning over the original must be re produced; through the test to determine the optimal exposure time of exposure, and to guide the adjustment of exposure operation; developering concentration and temperature, is developed according to the standard specification of the developing conditions.

- Q: How do I change the colors of printing plates into monochrome?

- Gray when I send it

- Q: Printing and make-up are the same

- Differently, there are two different steps. Typesetting and typesetting refers to the process of adjusting the position, size and layout of the visual information elements such as text, pictures, graphics and so on. According to the script type, plate row together in the newspapers for printing plate. Also known as the "edition make-up make-up", "group edition". The second processes in manual typesetting. According to the layout requirements of the printing unit, according to the contents of the original manuscript, the selected blanks and some typesetting materials are assembled into a movable plate of a certain size. Make up can be divided into parts: the imposition and imposition of two kinds of books.

- Q: What's the color of the print edition?

- If not a multi-color machine printed color, also easy for semi-finished product color is not easy to control the appearance of color. Generally do not use four-color printing, and the use of spot color printing. This is also a lot of printing plant monochrome, two-color printing spot color. Four colors, 8 colors, more four-color printing. 5 colors, usually printed four-color, plus a spot color, or over oil, etc..

- Q: Can I make a screen print?

- With these things, you can start the screen:1. mesh taut stick or nail on the prepared screen frame.2., the photosensitive coating evenly coated in the first step on the preparation of the screen (pay attention to coating evenly, smooth, no light transmission phenomenon)Then blow dry with a hair dryer3. and the back of a film patch ready in the above screen (attached to the outside) and then illuminated with a light source (can be the light of the sun, can also be a fluorescent lamp, also can be the hospital that ultraviolet tube for Deng can also, is a special version of the light (note must be the same network version film tightly, not have the gap between)

- Q: How do I reduce the layout of carton printing?

- After the base line is drawn, the top swing line, the box high speed line and the lower roll cover line can be drawn in accordance with the size of the corrugated box.

- Q: What does the PS version of the print mean?

- The light splitting type is used to print the original image of the positive image. The diazo compound in the non image part is broken down by the photolysis and dissolved by the developing solution. The diazo compound that remains on the plate is still not visible. PS version of the pro oil part is a high publication base plane about 3 m diazo photosensitive resin, is a good lipophilic hydrophobic film, ink is easy to spread on top, and water is difficult to spread on it. Diazo photosensitive resin also has good wear resistance and acid resistance. If the baking temperature of 230 ~ 240 DEG C for 5 ~ 8min, and the photosensitive film of enamel, but also can improve the hardness of the plates, plates rate up to 20 ~ 300 thousand. PS version of the hydrophilic part is three oxidation two aluminum film, high publishing base plane about 0.2 ~ 1 m, hydrophilic, wear resistance, chemical stability is better, so the printing plate printing rate is relatively high. PS version of the fine grain, high resolution, the formation of network clean and complete, so the color reproducibility, high image sharpness; a blank part of the PS version of the high moisture capacity, printing plate of large water consumption, water, Mo Pingheng easy to control.

- Q: What does the print edition mean?

- OffsetA lithographic plate is a graphic part and a blank part of a printing plate, basically in the same plane, and has the characteristics that the printing part is lipophilic and the blank part is hydrophilic.stencil printA plate is a picture of a plate, consisting of holes or meshes of different sizes or sizes.

- Q: Can screen printing be washed after use?

- Solvent ink, scrape residual color with diethylene glycol monobutyl ether wipes, and then wipe with kerosene.

Send your message to us

HD Metal Board, HD Aluminium Board, Recommended Sublimation Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords