Laminated Plywood/Formwork Concrete /Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

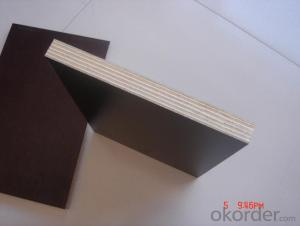

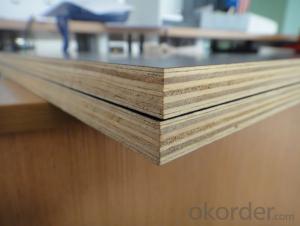

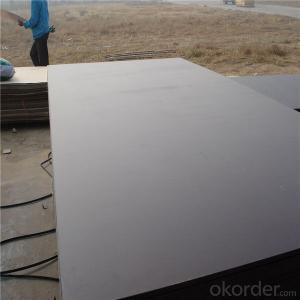

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

Product name | Laminated plywood/formwork concrete /film faced plywood |

Specification | 915*2135mm,1220*2440mm,1250*2500mm |

Thickness | 8-30mm |

Thickness Tolerance | +/-0.5mm-----+/-1.0mm |

Face/Back | Black, brown, red, anti-slip |

Grade | First grade |

Core | Poplar, hardwood, birch, combi, pine, agathis, pencil-cedar, bleached poplar and so on. |

Glue | WBP-phenolic, WBP-melamine, MR |

Moisture content | 8-13% |

package | Inner plastic bags, outer three-ply or paper-box, wrapped with steel tapes by 4*6 lines for reinforce. |

Certification | CARB,CE,ISO9001 |

Quantity | 8 pallets/20ft, 16 pallets/40ft,18 pallets/40HQ |

Price term | FOB,CNF,CIF,EXW |

Payment | T/T, 100% irrevocable L/C |

Delivery time | W15-20 days upon the receipt of 30%T/T deposit or L/C at sight |

Usages | Can be widely used in construction industry and other industry. |

Supply ability | 10000m³/month |

Remarks | Top class equipment with top class produce technique; Credit first, fair trading! |

Features

1) Good Raw Materials and High quality

2) More repeated using times

3) Good packing and fast shipment

4) Delivery the right products according to different level of requirement

5) High performance/price ratio

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

Products Photos

- Q: What are the allowable quantity differences in printed packaging materials?

- Light, bright colors for screen printing in India due to the leakage characteristics, so it can use a variety of ink and paint, not only can use the slurry, binder and pigment can also use coarse pigment. In addition, the method of screen printing ink preparation is simple, for example, it can be directly transferred into the light pigment ink, which is another main feature of screen printing. Screen printing products have strong light and have great advantages. Practice shows that the black ink coated paper embossing by measuring the scope of the use of the maximum density value, compared to 1.4, 1.6 and 1.8 letterpress, gravure, screen printing of the maximum density deviation range of 2 can be, therefore, the light screen printing products than other types of printing products lightfastness stronger resistance that is more suitable for outdoor advertising, signs of purpose.

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- As a screen printing material, semi automatic screen printing machine for printing or anti India, in particular circumstances, is usually anti India, India will.

- Q: Carton printing process and materials

- Flexo printing and gravure printing of corrugated carton processThese two processes are the first to roll paper printing paper, and then in the automatic corrugated cardboard production line to complete the production of corrugated cardboard. Carton printing quality and molding quality are relatively high, but the investment is relatively large, it is also not suitable for small batch production.In the domestic carton industry, three conventional corrugated carton printing methods are more common, and become the mainstream of corrugated box printing. And the new printing box system, due to equipment, materials, processes, operations and other technical hot spots have not yet been fully mastered, the investment is relatively large, the promotion of the difficulty is still relatively large. But in order to improve the quality of carton enterprises, reduce the total cost of cartons, to maximize profits and increase the competitive advantage in the market, it is imperative to adopt the new printing process.

- Q: What are the materials used in screen printing?

- Specifically, screen printing is mainly used in the following aspects: the art printing paper printing: advertising, jhenuk, calendar, lantern paper etc..Trademarks, printing, transfer printing, packaging, printing, building materials printing - wallpaper, etc. plastic printing plastic film - ethylene toys, bags, plastic bags and so on.Plastic plate -- false metal composite material and various labelsManufacturing parts - instruments.Wooden products printingHandicrafts - lacquerware, wooden arts and crafts, toys.Processing semi manufactured goods - sporting goods, boards, ceilings, road signs, signboards, fake metal wrenches, billboards, etc..Printing of metal productsMetal barrel, metal ware, metal product.Printing of glass and ceramic productsGlass -- mirrors, glass plates, cups, bottles, etc.Ceramic ware, arts and crafts.The label text plate, dial, shaped articles.The printed circuit boardPrinted circuit board, board for civil or industrial use, thick film integrated circuit board.The printing and dyeing cloth, printing and dyeing, flags, towels, handkerchiefs, shirts, vests, knitted fabrics etc.. 'Other printing - pockets, shoes, numbers, cloth, bags, backpacks, bags, schoolbags, etc..

Send your message to us

Laminated Plywood/Formwork Concrete /Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords