Best Quality HD Metal Board, HD Aluminium Board, Sublimation Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

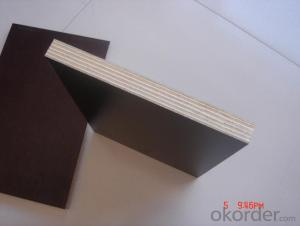

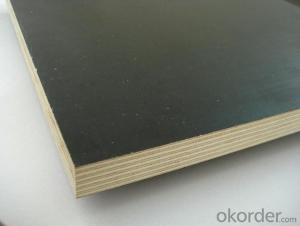

Sublimation Coated Aluminium Sheet

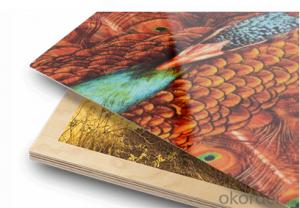

Sublimation aluminium sheet is manufactured specifically for sublimation printing

The hard surface coating on this aluminium is designed for improving image retention

Suggested heat transfer parameter: 200 ℃ and 40 seconds

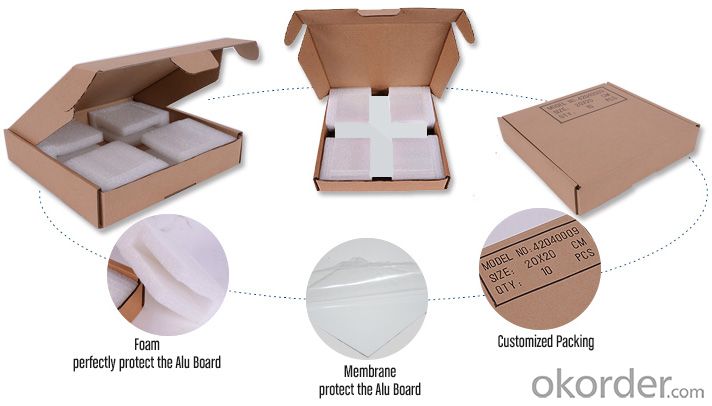

Safe packaging and film for protection

High quality coating for sublimation and high definition

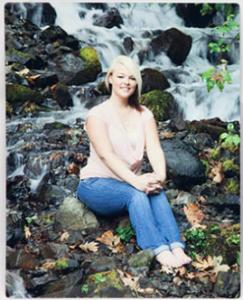

You can print any logo or pictures on it

Name of the product: Sublimation Coated Aluminium Sheet

Thickness: 0.45mm,0.55mm, other sizes as your customized

Size: 610*305mm,300*600mm,400*600mm,600*1200mm

Surface finish: Glossy, Matte, Satin, Pure,Pearlized,Brushed,Satin etc

Color: White,Silver,Gold,Cooper,Champange

Protection Film: PE,PVDF,PEVE,UV

Packaging: Seaworthy wooden pallet, wooden case or upon your request

Packaging & Delivery Packaging Details

Seaworthy wooden pallet, wooden case or upon your request

Delivery Detail

15~30 days after deposite

Weight of Packaging

1000 pics per pallet,Around 800 kg

Our advantage such as:

-Similar quality as as the top brand in USA(CHROMALUXE)

-Competitive price (much lower than others competitors)

-Cash Rebate policy and complete supports for distributors

These products are OK:

Sublimation Blanks

Heat press machine

DTG&UV pintor

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Our advantage such as:

-Similar quality as as the top brand in USA(CHROMALUXE)

-Competitive price (much lower than others competitors)

-Cash Rebate policy and complete supports for distributors

These products are OK:

Sublimation Blanks

Heat press machine

DTG&UV pintor

The free samples are available, we're pleased to offer you some for testing.

- Q: What is the printing plate roll made of? What are the materials?

- It not only prints organic objects such as PVC, but also prints complex objects such as metal, glass, ceramics and so on.

- Q: How to make the screen print surface smooth?

- You can use paint thinner on the back (pattern) paint wipe, repeat a few times, and check whether the pattern is transparent.If the number of prints is not large, the back should not be painted.

- Q: How to repair the printed circuit? How can the printed circuit board be broken by 1cm?

- The basic function of a printed circuit board is that the wires are the same except for the electronic support components. Therefore, the damaged part of the printed circuit board can be recovered after removing the dirt, coke marks and other foreign objects, and the connecting position can be restored by wires.

- Q: How can I place the printing rollers in the most convenient place?

- Usually standing, ah, corrugated and blankets on the roll, and outside to get a label, easy to manage. I am a plate factory, and I went to the printing plant is such a release, ha ha, the opportunity to cooperate on the best

- Q: What's the color of the print edition?

- In the subtractive primaries color (yellow, magenta, cyan and black printing). If you use yellow, magenta, cyan, black ink, four colored ink other than the color ink to copy the original color printing process, should not be called "four color printing", but should be called "spot color printing" or "point color printing."".With red, yellow, blue and black pigment (or dye ink) by lithographic printing method of full color copy of the subtractive color mixing principle.

- Q: How do I reduce the layout of carton printing?

- After the base line is drawn, the top swing line, the box high speed line and the lower roll cover line can be drawn in accordance with the size of the corrugated box.

- Q: How to prevent white leakage before printing?

- The most commonly used software (such as: PageMaker, QuarkXPress, Illustrator, FreeHand etc.) have built-in trap function, and the software can do some simple color and color to meet trap, as for the gradient colors and images are required to do trap work.

- Q: What does the PS version of the print mean?

- The PS version is an aluminum version for printing, specifically a PS version of the film!

- Q: Can screen printing be washed after use?

- The cleaning after the use of screen printing is very important, thoroughly clean the screen in the future use, there will be no blocking / deep light color problems, the service life is quite long.

- Q: Why is the screen printing broken?

- In the printing process, the version of film broke, mainly the process of plate making technical problems:1, the printing time is short, plastic film light curing is not sufficient, resulting in screen printing.2, before the plate, the mesh did not make degreasing treatment, resulting in photosensitive adhesive on the screen is not firmly, it is easy to break gel.

Send your message to us

Best Quality HD Metal Board, HD Aluminium Board, Sublimation Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords