Mg alloy Material and Industry field Application AZ31B magnesium plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mechanical Property

Alloy and Temper | Thickness (mm) | Yield Strength 0.2% offset (MPa) | Tensile strength (MPa) | Elongation In 5.65 √A (%) |

AZ31B-O | 0.35 – 1.5 | 125 | 221 | 10 |

1.5 – 6.3 | 105 | 221 | 9 | |

6.3 - 75 | 105 | 221 | 8 | |

AZ31B-H24 | 0.5 – 6.3 | 200 | 269 | 5 |

6.3 -9.5 | 179 | 262 | 7 | |

9.5 – 12.7 | 165 | 255 | 8 | |

12.7 - 25 | 152 | 248 | 8 | |

25- 50 | 138 | 234 | 6 | |

50 - 80 | 124 | 234 | 7 | |

AZ31B-H26 | 6.3 - 10 | 186 | 269 | 6 |

10 – 12.5 | 179 | 262 | 6 | |

12.5 - 20 | 172 | 255 | 5 | |

20 – 25 | 159 | 255 | 5 | |

25 - 40 | 152 | 241 | 5 | |

40 - 50 | 148 | 241 | 5 |

Size range

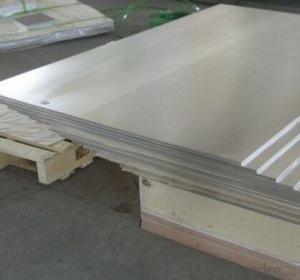

MaximumThickness: 0.5-300mm

Maximum width: 3000mm

Maximum length: 6000mm

Features of Standard Mg Plate

1. Magnesium is light metal, it’s ion exists widely in soil and water, and harmless to human body or environment.

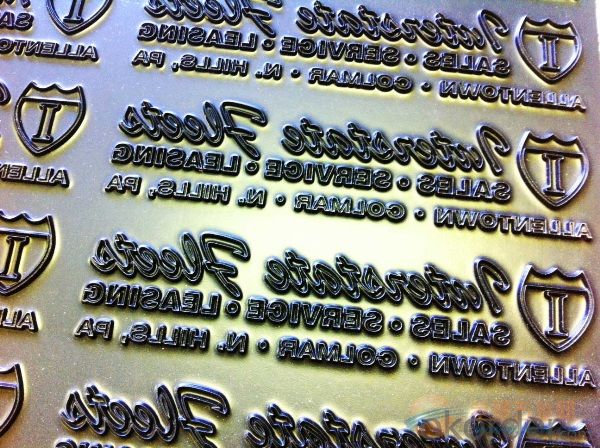

2. The Magnesium plates was etched very fast, normally within 3 minutes in the new chemical.

3. Magnesium photoengraving plate is lightest between Brass and Zinc plate. Therefor the magnesium engraving plate is better to be pasted and stamped.

4. No deformation happen during hot stamping process. Fast temperature rising, the stmping rate is more than 120000 times.

5. Magnesium engraving plate is easier to be etched with a highest speed between Brass and Zinc engraving plate. Normally magnesium engraving plate is to be etched in 1 mm deepth within 7 seconds.

6. The surface hardness of the magnesium plates is very close to the cooper.

7. The magnesium plate after rolling with 3000 tons cold rolling mill and also 2500tons hot rolling mill, then do the tempering treatment, our plates with uniform thickness, the tolerance of thickness is near zero, the plates is no anisotropy, eliminate the internal stress of the plates.

Features of Photoengraving plate

Magnesium photoengraving plate, come into the market in 1990’, was appreciated by its advantage. And then, the magnesium etching plate was adopt in some upscale and welcomed widely while the packing and painting industry developed soon. Recent years, also for magnesium photoengraving plate, due to the district requirement of environment and the heavy competitive, the down steam company have a higher requirement on the quality of the metal mould, so the magnesium photoengraving plate occupied the market a large part day by day, the quantity consumed by and the different application found out were growth rapidly. General trends, magnesium etching plate would replace the market of Brass and Zinc plate in the near future.

1. The photoengraving plates is made from process of multi-rolled, tempering, sanding, The sensitive glue in advance and Anti-corrosion paint back, coating,ect.

2. Our standard size: 500*1000mm, 610*914mm. other special size can be made based on.

3. Your requirement, normally thickness are 1.5mm 2.0mm 3.0mm 4.0mm 6.35mm 7mm.

Who are we:

CNBM Group

China National Building Material Group Corporation (CNBM) is the largest building materials and equipment group in China.

n Established in 1984 with approval from the State Council

n A Central Enterprise under direct supervision of SASAC in 2003

n Over 100,000 employees.

n 20 companies under direct management , among which 6 were listed companies, including 2 overseas listed.

If you want to know more information, please contact us or sent email to us.

- Q: How to make the screen print surface smooth?

- You can use paint thinner on the back (pattern) paint wipe, repeat a few times, and check whether the pattern is transparent.If the number of prints is not large, the back should not be painted.

- Q: Can you tell me how to make a good print?

- Control version dirty1, the printer will wipe the glass clean; remove the dust on the original manuscript, repair the defect on the original scratch; return the unqualified original, re production. For printing plate exposure caused by insufficient dirt, if dirt is not too serious, can supplement exposure using the diffusion sheet to move the position of the light exposure; can also improve the concentration of the developer, another developer.2, check the developering temperature and development time, and adjust to the corresponding standard; adjust the developer according to the formula given by manufacturer, update the developer; developing layout to fully clean water, the use of high-quality sponge layout; maintenance of automatic developing machine.3, in addition to dirty operation should be careful, apply brush to fill in except dirty liquid, except dirty, in addition to dirty time should be kept in 20, 30 seconds; in addition to dirty liquid use should be covered tightly; layout except dirty treatment, should use water fully flush.

- Q: How do I change the colors of printing plates into monochrome?

- Gray when I send it

- Q: How to repair the printed circuit? How can the printed circuit board be broken by 1cm?

- The basic function of a printed circuit board is that the wires are the same except for the electronic support components. Therefore, the damaged part of the printed circuit board can be recovered after removing the dirt, coke marks and other foreign objects, and the connecting position can be restored by wires.

- Q: The difference between the 60 and 100 lines of the printing roller

- The principle of letterpress printing is relatively simple. In gravure printing, printing machine inking device to make the ink distribution, then the ink transferred to the printing plate through the roller, due to the graphic part relief is much higher than that of the graphic part, on the plate and therefore, only the ink roller transferred to the printing elements, rather than the graphic part no ink.

- Q: How can I place the printing rollers in the most convenient place?

- Usually standing, ah, corrugated and blankets on the roll, and outside to get a label, easy to manage. I am a plate factory, and I went to the printing plant is such a release, ha ha, the opportunity to cooperate on the best

- Q: Can I make a screen print?

- Printing time can be decided by the light source used at that time. You can try more than onceAbove, this type of printing can only test the action, if used for regular production is not possible,If you want to get high-quality screen, but also have special equipment can, such as: dragnet machine, drying box, printer, and other related equipment and tools

- Q: How to prevent white leakage before printing?

- The most common trap techniques are Spread and Choke. Spread (commonly known as the "food") refers to the color version of outward expansion in the peripheral white trap overprint block yan. Choke (commonly known as "eat") and the concept of Spread instead, allow external color version inward extension trap. The use of two kinds of trapping techniques, all depending on color and light, the best is contained in the dark. Nothing is impossible in some cases, may be the result of Mixed trap line, Mixed refers to the white line trap is colored with two colors to meet color version produced by mixing color.

- Q: What does the PS version of the print mean?

- The light splitting type is used to print the original image of the positive image. The diazo compound in the non image part is broken down by the photolysis and dissolved by the developing solution. The diazo compound that remains on the plate is still not visible. PS version of the pro oil part is a high publication base plane about 3 m diazo photosensitive resin, is a good lipophilic hydrophobic film, ink is easy to spread on top, and water is difficult to spread on it. Diazo photosensitive resin also has good wear resistance and acid resistance. If the baking temperature of 230 ~ 240 DEG C for 5 ~ 8min, and the photosensitive film of enamel, but also can improve the hardness of the plates, plates rate up to 20 ~ 300 thousand. PS version of the hydrophilic part is three oxidation two aluminum film, high publishing base plane about 0.2 ~ 1 m, hydrophilic, wear resistance, chemical stability is better, so the printing plate printing rate is relatively high. PS version of the fine grain, high resolution, the formation of network clean and complete, so the color reproducibility, high image sharpness; a blank part of the PS version of the high moisture capacity, printing plate of large water consumption, water, Mo Pingheng easy to control.

- Q: What does the print edition mean?

- OffsetA lithographic plate is a graphic part and a blank part of a printing plate, basically in the same plane, and has the characteristics that the printing part is lipophilic and the blank part is hydrophilic.stencil printA plate is a picture of a plate, consisting of holes or meshes of different sizes or sizes.

Send your message to us

Mg alloy Material and Industry field Application AZ31B magnesium plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords