HD Metal Board, HD Aluminium Board, Sublimation Aluminium Board Supplier, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

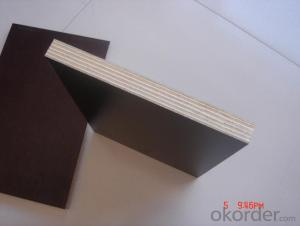

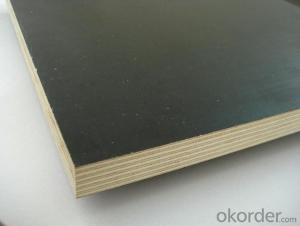

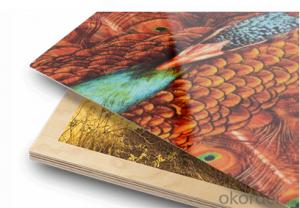

Sublimation Coated Aluminium Sheet

Sublimation aluminium sheet is manufactured specifically for sublimation printing

The hard surface coating on this aluminium is designed for improving image retention

Suggested heat transfer parameter: 200 ℃ and 40 seconds

Safe packaging and film for protection

High quality coating for sublimation and high definition

You can print any logo or pictures on it

Name of the product: Sublimation Coated Aluminium Sheet

Thickness: 0.45mm,0.55mm, other sizes as your customized

Size: 610*305mm,300*600mm,400*600mm,600*1200mm

Surface finish: Glossy, Matte, Satin, Pure,Pearlized,Brushed,Satin etc

Color: White,Silver,Gold,Cooper,Champange

Protection Film: PE,PVDF,PEVE,UV

Packaging: Seaworthy wooden pallet, wooden case or upon your request

Packaging & Delivery Packaging Details

Seaworthy wooden pallet, wooden case or upon your request

Delivery Detail

15~30 days after deposite

Weight of Packaging

1000 pics per pallet,Around 800 kg

What is WunderBoard HD metal prints?

Wunderboard is high-definition sublimation aluminum:

- Material: Aluminum

- Thickness: 1.14mm (0.045”)

- Biggest size: 1.2x1.2m (different/custom sizes are available)

- Finish: Glossy white

- Coating: 4 layers

--Water-proof, scratch-resistant and anti-UV.

Our advantage such as:

-Similar quality as as the top brand in USA(CHROMALUXE)

-Competitive price (much lower than others competitors)

-Cash Rebate policy and complete supports for distributors

These products are OK:

Sublimation Blanks

Heat press machine

DTG&UV pintor

The free samples are available, we're pleased to offer you some for testing.

- Q: What is the printing plate roll made of? What are the materials?

- It not only prints organic objects such as PVC, but also prints complex objects such as metal, glass, ceramics and so on.

- Q: How to make the screen print surface smooth?

- You can use paint thinner on the back (pattern) paint wipe, repeat a few times, and check whether the pattern is transparent.If the number of prints is not large, the back should not be painted.

- Q: Printing and make-up are the same

- Typography is sent to the customer file, can print that is the imposition of the same material file spell in a version according to the law, out of print

- Q: How to repair the printed circuit? How can the printed circuit board be broken by 1cm?

- The basic function of a printed circuit board is that the wires are the same except for the electronic support components. Therefore, the damaged part of the printed circuit board can be recovered after removing the dirt, coke marks and other foreign objects, and the connecting position can be restored by wires.

- Q: Can I make a screen print?

- With these things, you can start the screen:1. mesh taut stick or nail on the prepared screen frame.2., the photosensitive coating evenly coated in the first step on the preparation of the screen (pay attention to coating evenly, smooth, no light transmission phenomenon)Then blow dry with a hair dryer3. and the back of a film patch ready in the above screen (attached to the outside) and then illuminated with a light source (can be the light of the sun, can also be a fluorescent lamp, also can be the hospital that ultraviolet tube for Deng can also, is a special version of the light (note must be the same network version film tightly, not have the gap between)

- Q: How do I reduce the layout of carton printing?

- Carton printing typesetting reduction method: draw line, in the hanging plate in the circumferential direction required to shrink points, and in the horizontal direction without shrinking. The last version, the position to the horizontal and vertical direction alignment, pay attention to whether have tilted plate edge, falling, falling, tape print edition paper damage phenomenon, such as the emergence of the situation immediately take remedial measures.

- Q: How to prevent white leakage before printing?

- The most commonly used software (such as: PageMaker, QuarkXPress, Illustrator, FreeHand etc.) have built-in trap function, and the software can do some simple color and color to meet trap, as for the gradient colors and images are required to do trap work.

- Q: What does the PS version of the print mean?

- The PS version is an aluminum version for printing, specifically a PS version of the film!

- Q: What does the print edition mean?

- Plate (printing), referred to as a printing plate. A carrier for printing pictures on which ink is passed to the substrate.

- Q: Can screen printing be washed after use?

- Use water-based screen printing paste, scraping residue after color and washed with water again, then mixing with 1:1 triethanolamine wipes, water wash.

Send your message to us

HD Metal Board, HD Aluminium Board, Sublimation Aluminium Board Supplier, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords