Halogen Free VW-1 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

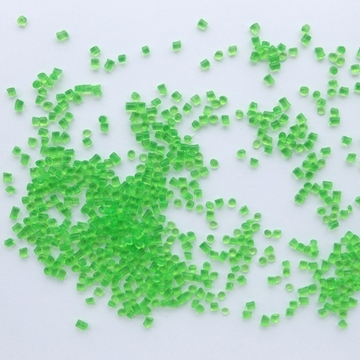

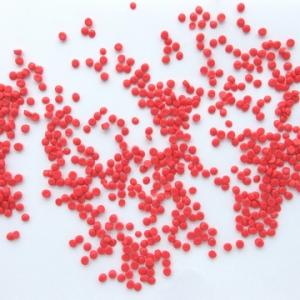

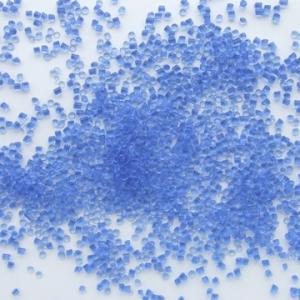

plastic granules:

VW-1 Flame Retardant Halogen Free TPE Cable Compound

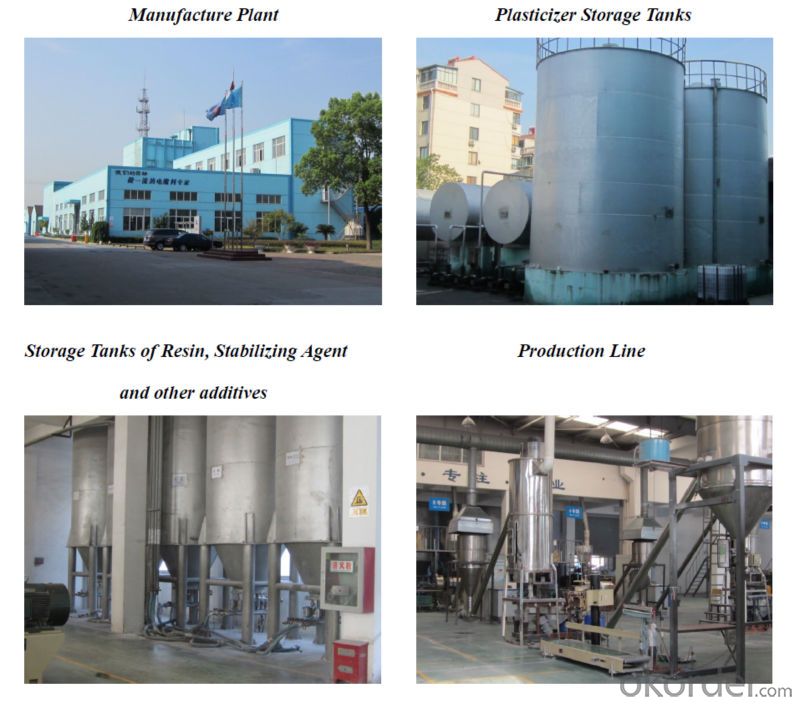

plastic granules: 1, Type and application: Used for USB data cable, HDMI high-frequency cable and communication cable 2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has storage time exceeding one months. 4, Storage and transport Packaging:20kg/bag,Aluminum foil and PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: ItemUnitTypicalE3675AE3680AE3685AEC3685ES3685E3688AE3690AE3656DDensityg/cm31.05±0.031.05±0.031.07±0.031.08±0.031.11±0.031.06±0.031.14±0.031.10±0.03HardnessShore A75±380±385±385±385±388±390±397±3230°C×5kgMelt Indexg/10min2.42.51.11.81.21.21.10.8Tensile StrengthMPa10.512151111141222Elongation at Break%350310290230210260250210Thermal aging°C*h121°C*168hTS retention≥75%9599101999810196104EB retention≥75%7980798282858078Hot deformation°C*h150°C*1hVariation≤50%--3612272726174Oxygen indexO2 %2526272725272626Impact BrittlenessTemperature-60 °CPassPassPassPassPassPassPassPassVolume Resistivity,at 20°C ≥1×1014Ω m3.9×10144.6×10145.1×10143.2×10143.6×10145.3×10144.7×10145.1×10146,Company Pictures

|

- Q: I'd like to know what PP plastic material is PP plastic raw materials cleaning can not use ultrasonic cleaning machine to wash it?

- PP plastic raw material is a thermoplastic resin. Its density is small, strength, stiffness, hardness, heat resistance are better than low-pressure polyethylene, can be used in about 100 degrees. With good electrical properties and high frequency insulation, free of moisture, but brittle at low temperatures, wear and aging, suitable for making general mechanical parts, corrosion resistant parts and insulation parts.

- Q: What plastic material has great impact resistance?

- The ability of metal materials, machinery parts and components to resist impact damage is called impact strength.

- Q: What is the disposable transparent plastic cup?

- PC: colorless transparent material, suitable for making instruments, small parts, insulation, transparent parts and impact parts.Transparent ABS, this material is expensive, in the field of decoration, packaging and other promising.

- Q: What is the difference between PP raw material and modified PP?

- PP raw materials refer to resinsConcept: the word "plastic" in the word "plastic material" is intended as a material or plastic material that can be arbitrarily shaped into various shapes. In the dictionary is defined as "synthetic or natural polymers as the main component, under certain conditions can plasticization and molding can keep shape, the end product of materials.

- Q: What machines and materials are needed for the manufacture of disposable plastic cups?

- The dryer is moving in the same direction in the process of system design with the temperature reducing water vapor return material prepared to go back to the problem; in the process of drying, hot air flow from the tail to move forward, fully contact with the material, the heat conduction, convection and radiation heat transfer and make full use of heat energy; will be passed directly to the material, the material in the water the cylinder has been evaporated, inlet draught device will flow out of a large number of moisture, moisture, prevent dust pollution two efflux caused by internal spiral; stirring, sweeping, copy board, promote the movement of materials, complete the whole drying process; inverse spread guide avoid dehydration, reduce duplication of drying process.

- Q: What raw materials do plastic color printing plants use?

- Mainly plastic film and ink, the film is generally in accordance with the nature and requirements of products such as PVC film, POF film

- Q: Application of CPE in plastics industry

- Chlorinated polyethylene (CPE) for saturated polymer materials, the appearance of white powder, non-toxic and tasteless, has excellent weather resistance, ozone resistance, chemical resistance and aging resistance, good oil resistance, flame retardancy and coloring properties.

- Q: What does plastic material include?

- Plastic bags are the main raw materials of polyethylene and polyvinyl chloride, are non degradable. The main raw material for the production of plastic bags and polystyrene, polypropylene polymer, waste plastic packaging into the environment, because of its difficult degradation, will cause deep ecological environment problems, the long time. Waste plastic packaging is mixed in the soil, affecting crops absorb nutrients and moisture, will lead to crop failures; abandoned waste plastic packaging on land or in the water, animal as food ingestion, will lead to the death of the animal.

- Q: What are the raw materials for producing plastic films?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.

- Q: I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- There are PC lensesThe PC material is more impact resistant than polymer resin, often used in aviation equipment transparent windows, police on the mask, and the astronaut's helmet mask, it is only about 1/10 the weight of glass, resin lenses compared with traditional is only half of the weight.

Send your message to us

Halogen Free VW-1 Flame Retardant Thermoplastic Elastomer Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords