Halogen Free Flame Retardant Thermoplastic Elastomer Compound for Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

plastic granules:

Halogen Free Flame Retardant TPE Compound used for power cable

plastic granules: 1, Type and application: Used for Japanese standard power cable and electrical equipment cable

2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has been stored more than one month. 4, Storage and transport Packaging:20kg/bag,Aluminum foil and PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: |

Item | Unit | Typical | |||||||

E3685A | E3688B | E3690A | E3692A | E3692B | E3689A | ED3685 | EA3685 | ||

Density | g/cm3 | 1.11±0.03 | 1.09±0.03 | 1.14±0.03 | 1.08±0.03 | 1.10±0.03 | 1.10±0.03 | 1.10±0.03 | 1.10±0.03 |

Hardness | Shore A | 85±3 | 88±3 | 90±3 | 92±3 | 92±3 | 89±3 | 85±3 | 85±3 |

Melt Index 230℃×5kg | g/10min | 1.2 | 2.6 | 1.1 | 1.0 | 0.8 | 1.5 | 1.3 | 2.0 |

Tensile Strength | MPa | 15 | 12 | 13 | 16 | 13 | 14 | 12 | 11 |

Elongation at Break | % | 280 | 260 | 250 | 270 | 260 | 260 | 240 | 300 |

Thermal aging | ℃*h | 136℃*168h | |||||||

TS retention | ≥75% | 97 | 99 | 101 | 102 | 101 | 97 | 99 | 109 |

EB retention | ≥75% | 83 | 81 | 79 | 82 | 80 | 81 | 82 | 78 |

Hot deformation | ℃*h | 150℃*1h | |||||||

Variation | ≤50% | 15 | 13 | 12 | 8 | 6 | 9 | 7 | 38 |

pH of gases evolued | -- | 6.3 | 6.5 | 5.3 | 5.6 | 6.2 | 5.6 | 5.5 | 5.3 |

Conductivity of Gases evolved | ≤μm/mm | 1.4 | 1.3 | 1.5 | 1.2 | 1.1 | 1.2 | 1.0 | 1.3 |

Oxygen index | O2 % | 26 | 27 | 27 | 27 | 26 | 27 | 27 | 27 |

Impact Brittleness Temperature | -60 ℃ | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass |

Volume Resistivity, at 20℃ | Ω﹒m | 3.7×1014 | 3.5×1014 | 4.3×1014 | 3.5×1014 | 3.2×1014 | 4.1×1014 | 4.3×1014 | 5.4×1014 |

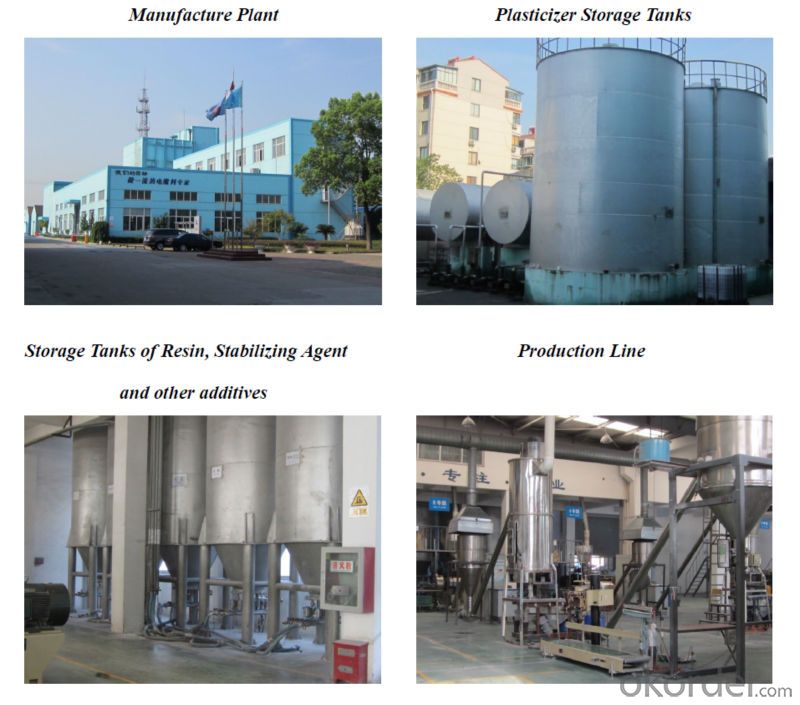

6. Company

- Q: I'd like to know what PP plastic material is PP plastic raw materials cleaning can not use ultrasonic cleaning machine to wash it?

- After research, "ultrasonic cleaning machine" function is that as long as the liquid can be immersed in the sound field, the product exists in the cleaning role, and the cleaning speed, high quality. Especially for PP plastic raw materials, under the action of ultrasound, it takes only 5-10 minutes to complete. The speed is several times as many as that of the traditional method, and the cleanliness is also high.

- Q: Plastic raw materials, electroplating grade round face, electroplating grade, what is the concept?

- Such as ABS727 and so on. For example, plastic plating material can not add any gate material, that is because the material may be part of the carbonization, leading to local polarity reduction, will form electroplating pores.

- Q: What are the POE plastic raw materials?

- POE classification of plastics raw materials:Plasticizing properties: Thermoplastics and thermosetting plastics.Divided by use: General Plastics and engineering plastics.

- Q: Plastic raw materials, why LDPE and LLDPE?

- LDPE is low density polyethylene, that is, high pressure material; LLDPE is linear material.

- Q: What are the plastic bags made of?

- General civilian products, mostly polyethylene (PE) to do, PE is divided into low pressure high-density HDPE, low pressure high-density LDPE and linear low-density LLDPE

- Q: What kinds of plastic properties can be divided into thermal properties?

- Classification of plastics (100 million nylon)There are many kinds of plastics. There are many kinds of classification methods. They are usually divided into two categories: thermoplastic and thermosetting plastics according to the change of their properties after heating.

- Q: What are the raw materials needed for producing plastic hair dryer shell and flashlight shell?

- PA nylon as a large amount of Engineering plastics. Widely used in machinery, electrical appliances, textile equipment, chemical equipment, aviation and other fields. Become an indispensable structural material in all walks of life, the main features are as follows:1. excellent mechanical properties. High mechanical strength and good toughness.2. excellent heat resistance. Such as nylon 46, high crystallinity Nylon high thermal deformation temperature, can be used at 150 degrees Celsius for a long time. PA66 after glass fiber reinforcement, its thermal deformation temperature above 250 degrees celsius.3. excellent electrical insulation performance. Nylon has high volume resistance and high breakdown resistance. It is an excellent insulating material for electrical and electrical equipment.4. self lubrication, good friction resistance. Nylon has a good self lubrication, small friction coefficient, so as to drive parts, long service life.5. excellent weather resistance.

- Q: Does plastic raw material ENBA have toughening effect?

- EMA can be used as toughening agent for alloy such as PBT/PC and PC/ABS.

- Q: What are the raw materials made of modified plastics?

- Broadly speaking, the modification is to change the original performance, such as TPU, flame retardant, anti UV and so on; a narrow sense, the industry will be the new material of TPU polymerization, production is not called modified, and those who buy TPU new material made of flame retardant TPU, called "back modified". The modification process involves adding some resins or additives.

- Q: I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- PC lenses also have an important feature, that is, PC lenses have the effect of isolating harmful ultraviolet rays, but their disadvantages also include surface scratching easily.

Send your message to us

Halogen Free Flame Retardant Thermoplastic Elastomer Compound for Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords