EPS Wire Mesh Panel Used in Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Square Meters watt

- Supply Capability:

- 3000 Sheets per Day watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

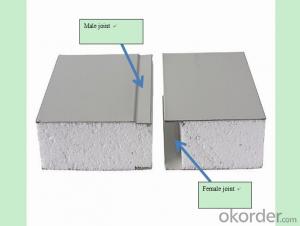

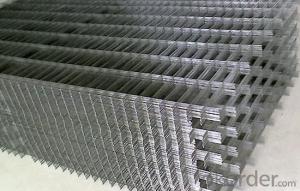

3D EPS Wire Mesh Panel

PVC coating & powders coating

Material:Hot dipped galvanized wire

Raw material:Q235,Q195

ISO9001:2008 3D EPS Wire Mesh Panel

Technical Note of 3D EPS Wire Mesh Panel:

1,Standard roll length: 2.5m, 2.255m, 2.0m, 2.2m and others as requests

2.Width: 0.5m to 1.8m

3,Special sizes available at request

4,Packing: in waterproof paper in rolls. Customer’s packing available at request.

It can be used in

highway, railway, road, city transit, factory zone, industry zone, private grounds, public places

The surface treatment of welded wire fence include

electro galvanized, hot-dipped galvanized, PVC coated

Production Processes of 3D EPS Wire Mesh Panel:

Using high quality wire rod as raw material, the welded panel, after galvanized, powders primer, and powders top coating, it can resist the

corrosive and ultraviolet radiation very strongly.

- Q: What is the plastic basin made of?

- The raw material is PP and PE, the raw material price is more than 10000, and some can be recycled at around 5000.

- Q: Is plastic bucket and plastic bottle the same raw material?

- When the number of the triangle in the bottom of the plastic barrel is 5, the main component of this kind of plastic barrel is polypropylene, or PP. The melting point of this kind of plastic barrel is relatively high, reaching 167 degrees centigrade, and can be recycled after cleaning. Compared to PE plastic barrels, PP plastic barrels of heat resistance slightly better, but the higher temperature there is the risk of softening and melting, use should avoid high temperature.

- Q: How many types of plastic materials are there?

- Plastic classification, composition and characteristics, plastic is a widely used synthetic polymer materials, in our daily life, plastic products abound. We wake up from the use of toiletries, the breakfast dishes, to work with the rest of the stationery, with cushions, mattresses, and TV, washing machine, computer shell, and night gave us the light of the lamps in various shapes...... Plastics have gradually replaced many materials and utensils that have been used for decades and centuries with their excellent performance, becoming an indispensable assistant in people's life. Plastic, metal in hard wood, light transparent glass ceramics, corrosion resistance, rubber elasticity and toughness in a body, in addition to daily necessities, plastic more widely used in aerospace, medical equipment, petroleum chemical industry, machinery manufacturing, defense, construction and other industries.

- Q: How is plastic material made out?

- At present, resins are polymers that have not yet been blended with additives. Resin accounts for about 40% to 100% of the total weight of plastics. The basic properties of plastics depend mainly on the nature of the resin, but additives also play an important role.

- Q: What is plastic film material?

- You should first say what type of plastic film you are going to make. You should make a bag or make a plastic wrap. The type is different. You should see what determines what material to use, and the plastic film is also divided into many kinds

- Q: What kinds of plastic properties can be divided into thermal properties?

- Classification of plastics (100 million nylon)There are many kinds of plastics. There are many kinds of classification methods. They are usually divided into two categories: thermoplastic and thermosetting plastics according to the change of their properties after heating.

- Q: What plastic material is resistant to high temperature?

- PPS is a kind of special engineering plastics with excellent comprehensive performance. Dimensional stability of PPS has excellent temperature resistance, corrosion resistance, radiation resistance, flame retardant, balanced and excellent physical and mechanical properties and excellent electrical properties and other characteristics, are widely used as structural polymer materials, by filling after modification, widely used in special engineering plastics. At the same time, it can be made into various functional films, coatings and composite materials. It has been successfully applied in the fields of electronics, electrical appliances, aeronautics and Astronautics, automobile transportation and so on. Domestic enterprises have actively developed and formed a certain production capacity, which changed the situation of relying solely on imports in the past. However, there are still some problems in China's PPS technology, such as low variety of products, high functional products, and urgent expansion of production capacity, which will be the focus of the next development of PPS.

- Q: What is the raw material for producing corn starch plastic film?

- According to the current technical level, the production of 1 tons of starch requires 1.5 tons of corn, power consumption of 200KWh, coal consumption of 0.3 tons. If the 1 tons of starch into biomass plastics, can be processed into 1.01.2 tons of products, instead of common plastics, saving petrochemical resources, the country. Because there is no effective stimulating mechanism in the downstream market, the application of corn starch is still limited to the research area of modified starch. The industrialization of biomass plastics with corn starch as the main raw material will effectively stimulate the cultivation of corn and the production of cornstarch. Biomass plastics are gradually evolved from the further research and development of biodegradable plastics. It is gradually recognized that only by fully utilizing the natural and recyclable plant resources to develop and develop biomass plastics is a reliable way to achieve sustainable economic development. In the past 30 years, and in half a century, all countries in the world pay attention to and invest a lot of manpower and material resources of biomass plastics, mainly starch and biodegradable plastics mixing, carbon dioxide copolymer, biosynthesis of biodegradable plastics, and then generate a biosynthetic precursor chemical polymerization of biodegradable plastics in 4 categories. The latter three prices are higher, but the cost is higher, mainly used in medical materials, biomedical engineering and tissue engineering and other high-value products.

- Q: What are the raw materials made of modified plastics?

- Plastic modification is to petrochemical production out of large quantities of general resin through physical, chemical, mechanical, improve or increase their capabilities to special environmental conditions in electricity and magnetism, light, heat, aging resistance, flame retardancy, mechanical properties and other aspects of the use function. Modified plastics is a plastic industry involving a wide range of areas, high technology content, and the modification technology of plastics - filling, blending and modification is raw materials and processing plastic products into almost all of the. From the production of raw material resin to the modification of plastic masterbatch from various specifications and varieties, in order to reduce the cost of plastic products and improve their functionality, the plastic modification technology can not be separated

- Q: What are the raw materials for producing plastic films?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | HACCP ;ISO 9001:2000 ;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | tianjin,huanghua,ningbo |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, French |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

EPS Wire Mesh Panel Used in Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Square Meters watt

- Supply Capability:

- 3000 Sheets per Day watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords