Halogen Free Non Flame Retardant Thermolastic Elastomer compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

plastic granules:

Halogen free non-flame retardant TPE cable compound

plastic granules: 1, Type and application: Used for non-flame retardant data cable

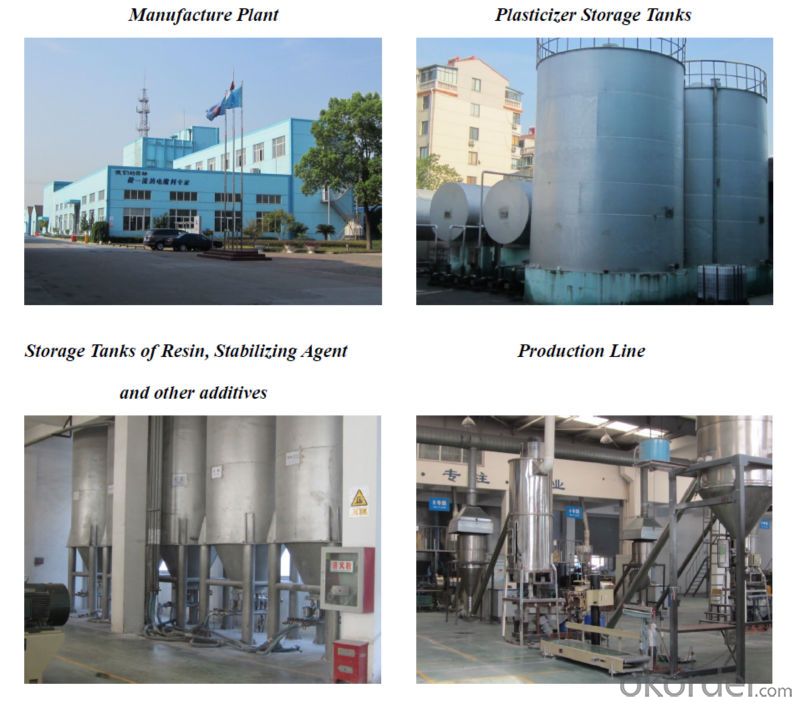

2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has been stored more than two months. 4, Storage and transport Packaging:20kg/bag,PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: 6,Company Pictures

|

- Q: What are the raw materials of foam plastics and how do they come out?

- Chemical blowing agents are mainly azo organic compounds such as azo two formamide (ADCA or AC), 2, 2 '- azo two, DAB, AIBN, etc.. This kind of foaming agent is cheap, and the products are non-toxic, odorless and colorless. In addition to sulfonylhydrazine, such as 4, 4 '- oxo benzene sulfonyl hydrazide (OBSH) etc.. Attention should be paid to the decomposition temperature. The properties of chemical foaming agents are as follows:Azo two formamide (AC, ADCA). Orange crystalline powder. A large amount of gas (N2, CO and a small amount of CO2) is decomposed at 120 DEG C, and the gas yield is 200 ~ 300mL/g in the standard state, which is an efficient foaming agent.

- Q: What material is best for plastic gears?

- Gears can be made of PA, POM, etc., but PA and POM will have noise at high speeds.

- Q: What material is good for plastic bellows?

- In the next case, it is recommended to use PP (polypropylene) bellowsNo strong acid and high concentration of oxidant in the environment; in more than 80 degrees Celsius in the environment of soluble in benzene, toluene and other aromatic hydrocarbons and chlorinated hydrocarbons in oil absorption; for most stable, small amount of mineral oil and vegetable oil.Mainly used in the temperature range of -20 to 120 degrees Celsius environment; used in automobiles, motorcycles and other motor vehicle wire harness sheath; also used for household appliances, precision machine tools and other equipment wiring wire sheath.

- Q: What is the concept of plastic raw materials for turnover containers?

- Plastic turnover box, other features: 1) plastic turnover box outer dimension refers to the maximum size of the logistics box cover. 2) the plastic turnover box has no standard inner concave, and the case size is 18mm. 3) the carrying capacity of a plastic turnover box means that the load is uniformly placed within the range of the environmental temperature. 4) the effective working temperature of the plastic turnover box is -25 DEG C - 40 DEG C. 5) plastic turnover boxes can be stacked for storage, saving space.

- Q: What are the plastic raw materials?

- Plastic raw material is a kind of polymer (polymer), also known as macromolecule or macromolecule, also is commonly known as plastic or resin. The so-called plastic raw material, in fact, it is a kind of [synthetic resin], the shape of the natural resin [pine resin] similar, but because of the chemical strength of the synthesis, and is called plastic.

- Q: What is plastic material E-PET?

- I'm in the chemical industry.PET is polyester. Never heard of the E PETI doubt if you said that the E-PET E is not an abbreviation for electric, an insulating PET that can be used to make PET electrical insulating films.

- Q: That kind of plastic bottle blows well

- PVCSoft, tough, good plasticity, can be made into transparent and various colors, commonly used transparent PVC packaging cosmetics categories of plastic bottles.

- Q: What are the raw materials for producing plastic bowls and cups?

- Mostly PP, PE, these two.

- Q: What two ingredients fit together to solidify like plastic?

- Secondly, whether or not the material can be calibrated in accordance with the displacement sensor (or embedded in it), and then the gap distance is measured by reading after installation.

- Q: What is the difference between plastic particles and raw materials?

- PVC is a PVC, bright color, corrosion resistant and durable. Due to an increase in the manufacturing process of plasticizer, anti ageing agent assisted a number of toxic materials, so their products generally do not store food and drug.

Send your message to us

Halogen Free Non Flame Retardant Thermolastic Elastomer compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords