Environmental Friendly Halogen Free Flame Retardant Nylon Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nylon compound:

1. Competitive price

2. Customized products

3. Stable quality

4. 30 years of experience

Nylon compound:

1. Applications of Nylon compound:

Used as special jacket for railway, locomotive, and communication optical cables etc, of which operation temperature is at 125 degree C.

2. Descriptionof Nylon compound:

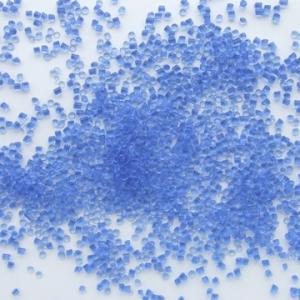

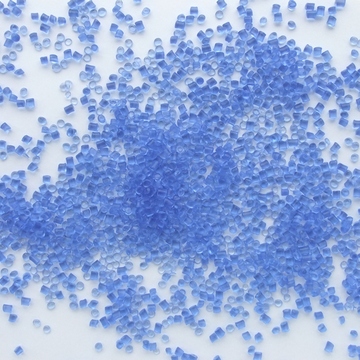

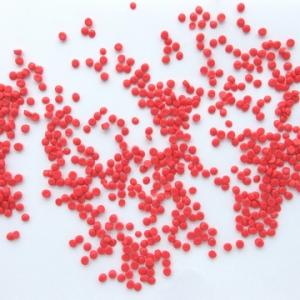

Safe environmental friendly flame retardant nylon jacket compound, based on nylon resin, is produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3. Processing of Nylon compound:

The compound can be processed with conventional extruders. The L/D should be greater than or equal to 25; and the compression ratio of screw should be greater than 1:2.5.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

temperature °C | 220 | 240 | 245 | 245 | 240 | 240 |

Note:Compound should be dried at 100°C before use, if it was stored more than one months.

4. Storage and transport of Nylon compound:

Packaging:25kg/bag,Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. Properties of Nylon compound:

Item | Unit | PA5001 | PA4001 | ||

Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.22 | -- | 1.25 |

Hardness | Shore D | -- | 68 | -- | 68 |

Tensile Strength | ≥MPa | 30 | 62 | 30 | 60 |

Elongation at Break | ≥ % | 200 | 260 | 200 | 250 |

Thermal Aging | °C×h | 158×168 | 158×168 | ||

TS/EB Retention | ≥ % | 75/75 | 90/85 | 75/75 | 90/88 |

Oil resistant test Immersion in ASTM2# | °C×h | 100×70 | 100×70 | ||

TS/EB Retention | ≥ % | 40/40 | 23/27 | 40/40 | 24/28 |

Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1012 | 1.1×1013 | 1.0×1012 | 2.3×1013 |

Oxygen Index | ≥ | 28 | 30 | 28 | 31 |

Low temperature winding | -40 | -50 | -40 | -50 | |

Dielectric strength | MV/m | --- | 24 | --- | 24 |

UL Class flame retardant | --- | VW-1 | --- | VW-1 | |

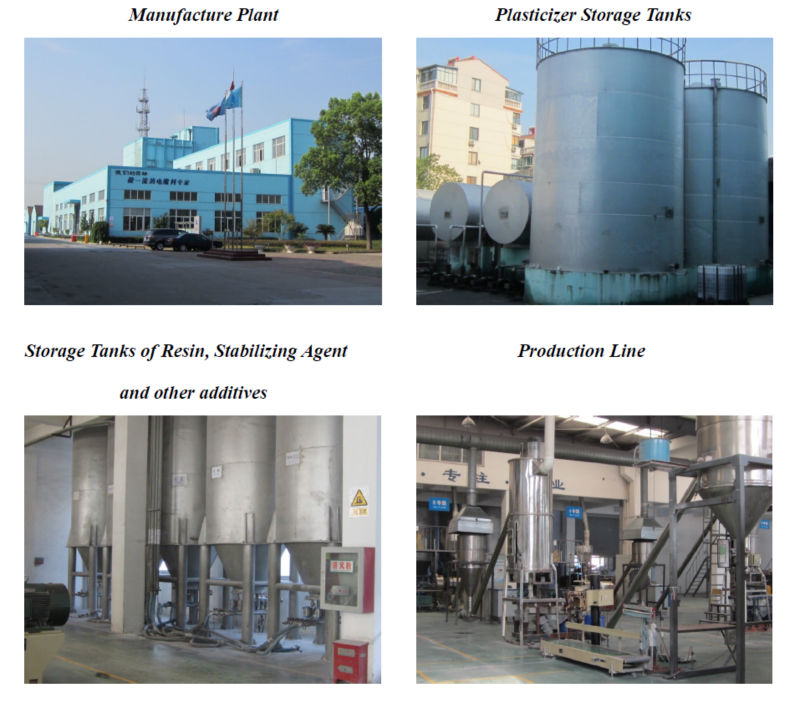

6. Company

- Q: How are plastic products made? What is the raw material of plastics?

- Plastic products are divided into: injection molding, blow molding, spray molding, blister, and die casting. Plastic material is oil. It must be done at a high temperature. The mold you call is usually steel.

- Q: The difference between resin and plastics

- Plastic refers to the resin (or in the process of using monomer polymerization) as the main ingredient, such as plasticizers, fillers, lubricants, additives such as colorants as auxiliary components, can flow in the process of forming materials, but also can be said to be material with resin as the main raw material and has plasticity and product. Plastic generally refers to finished products, such as plastic cups, plastic bowls and so on.

- Q: What is the material of plastic dip?

- Also known as alias dip coated, hot dip coating, hot compress. Dip (plastic) is a kind of plastic coating process. According to the different raw materials used in dipping, they can be divided into liquid dipping (coating) and powder dipping (coating).

- Q: What can recycled plastics do?

- The source of waste plastic materials, where there was a waste plastic, easy to buy, cheap (around, so) a city daily consumption of plastic bags and other plastic products reached more than 10 tons in rural areas have a lot of plastic waste plastic particles Recyclable, don't worry about sales. Suitable for partnership enterprises, laid-off workers and individual production. Gong Zhen Xiao Mao CI is the history of Chin Shan recycled plastic base professional manufacturer and supplier. Hedong District, Shandong City, Linyi province has built the largest national renewable plastic base in china.

- Q: What are the APP of plastic raw materials?

- Thermoplastic engineering plastics (polyamides, polycarbonates, POM, PET, PBT and others)

- Q: What are the raw materials for vest plastic bags?

- Shrink film (Shrinkfilm) is a thermoplastic film that is stretched in production, directed, and contracted by hot air treatment or infrared radiation during use. After heat treatment, the film is wrapped tightly in the package, and the shrinkage force reaches the maximum value in the cooling stage and can be stored for a long time.

- Q: What plastic material is resistant to high temperature?

- PPS is a kind of special engineering plastics with excellent comprehensive performance. Dimensional stability of PPS has excellent temperature resistance, corrosion resistance, radiation resistance, flame retardant, balanced and excellent physical and mechanical properties and excellent electrical properties and other characteristics, are widely used as structural polymer materials, by filling after modification, widely used in special engineering plastics. At the same time, it can be made into various functional films, coatings and composite materials. It has been successfully applied in the fields of electronics, electrical appliances, aeronautics and Astronautics, automobile transportation and so on. Domestic enterprises have actively developed and formed a certain production capacity, which changed the situation of relying solely on imports in the past. However, there are still some problems in China's PPS technology, such as low variety of products, high functional products, and urgent expansion of production capacity, which will be the focus of the next development of PPS.

- Q: What does plastic material include?

- Method for identifying toxic plastic bags. Water detection method: put a plastic bag into the water, non-toxic can be surfaced, and poisonous won't rise; hand touch detection method: white or colorless transparent is non-toxic, the hand has a sense of lubrication, the surface like wax; color: color detection method of toxic haze or yellow, red and black. Feel sticky; jitter method: take a plastic bag shaking, the sound crisp sound stuffy astringent toxic and non-toxic.

- Q: Chemical, plastic raw materials, plastic raw materials how sub grade?

- Plastic bucket is usually added to the resin, in the production of lubricants, plasticizers, dispersant, pigment, polyethylene wax, and these materials good variety, price range, and some high melting point, good whiteness, production out of the finished product is good texture, high brightness, good conscience manufacturers add some heat thermoplastic elastomer, feel very well; and a point of the raw materials, the relative performance is low, the production of plastic barrels must be of poor quality.

- Q: Is plastic raw material rubber?

- The difference between the plastic and the rubber is plastic or not, but because of thermosetting plastics, this definition is not comprehensive. Another difference is whether the elastic body, but because of the appearance of thermoplastic elastomer, this definition is not comprehensive. In general, rigid high molecular material thermoplastic processing, sure is a plastic elastomer; and thermosetting rubber must be classified. The more ambiguous reference history. Silicone rubber and polyurethane is thermosetting elastomer rubber, is, but completely different from natural rubber. There is a part of polyurethane is thermosetting plastics, even thermoplastics, composition, structure and it depends on the characters.

Send your message to us

Environmental Friendly Halogen Free Flame Retardant Nylon Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches