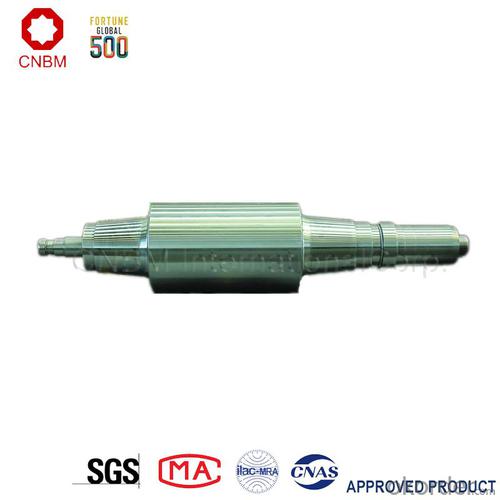

Alloy Roll with High Wear Resistance and High Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company Profile

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM Group is integrated with four business segments: Manufacture, R&D,Sets of equipment and Logistics trading.Mill rolls are our main products.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 120 countries and regions all over the world.

The product introduction of mill roll

Equipped with advanced technological facilities on melting, casting, forging, heat treating and mechanical machining, our factory has formed 9 professional complete roll manufacturing lines of cast steel, cast iron and forged steel rolls such as strip mill rolls, heavy section mill rolls, wire & bar rolls, special shaped rolls and small-sized cold rolls and specialized production lines of bloom and slab CCM, coke oven equipments and wind power products. Annual production capacity of mill rolls is 500,000 tons, metallurgical equipment is 80,000 tons.

Workshop

Workshop is the core of our company and undertakes all of scientific research work. The company specially produces and supplies all kinds of roll used for hot strip mill, cold strip mill, plate & heavy plate mill, large-sized section mill, universal mill etc.

Products & Specification

Products & Specification

| Mill | Application | Material | Product Specification | ||

| Hot Strip Mill | Large-sized vertical roll | Special alloy cast roll, Adamite | All Sizes | ||

| Small-sized vertical roll | Adamite, HiCr iron | ||||

| Roughing work roll | Special alloy cast steel, Adamite, HiCr steel, Semi-HSS, HiCr iron | ||||

| Finish rolling | Early stand work roll | HiCr iron, HSS | |||

| Later stand work roll | ICDP, HSS | ||||

| Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |||

| Alloy forged steel | D≤¢2000,W≤75t | ||||

| Temper rolling | Work roll | HiCr iron | All Sizes | ||

| Alloy forged steel | |||||

| Back-up roll | ICDP | ||||

| Duplex cast steel | D≤¢2000, W≤80t | ||||

| Alloy forged steel | D≤¢2000, W≤75t | ||||

| Mill | Application | Material | Product specification |

Cold strip mill & Single stand cold mill | Work roll | Alloy forged steel | All Sizes |

| Intermediate roll | Alloy forged steel | ||

| Temper roll | Alloy forged steel | ||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | |

| Alloy forged steel | D≤¢2000,W≤75t | ||

Largesized universal structural mill | Break-down roll | Special alloy cast steel, alloy nodular iron | All Sizes |

| Horizontal collar | High carbon adamite (duplex) | ||

| Vertical collar | High carbon adamite, HiCr iron | ||

| Edger roll Edger roll | High carbon adamite | ||

| Shaft | Alloy forged steel |

| Mill | Application | Marterial | Product Specification | |

| CSP | Vertical Roll | Adamite, Special alloy cast steel, HiCr iron | All Sizes | |

| Roughing work roll | Semi-HSS, HiCr Steel | |||

| Finish rolling | Early stand | HiCr iron, HSS | ||

| Later stand | ICDP, HSS | |||

| Roughing & Finishing back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Steckel Mill | Vertical roll | Adamite, Special alloy cast steel | All Sizes | |

| Roughing work roll | ICDP, HiCr iron | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

| Plate & Heavy plate mill | Rough rolling | 2-hi work roll | Special alloy cast steel, Tool steel | All Sizes |

| 4-hi work roll | HiCr iron, ICDP | |||

| Finishing work roll | HiCr iron, ICDP | |||

| Single stand work roll | HiCr iron, ICDP | |||

| Back-up roll | Duplex cast steel | D≤¢2000,W≤80t | ||

| Alloy forged steel | D≤¢2000,W≤75t | |||

Quality Control

The company has the most advanced experimental and testing equipments in global mill roll industry, including direct-reading spectrometer, spectrum analyzer , X-ray fluorescence analyzer, scanning electronic microscope, energy disperse spectroscopy, X-ray diffractometer, image analyzer, high/low temperature metallographic microscope, X-ray stress meter, brittleness temperature tester, thermal analogue machine, dilatometer, macro and micro hardness tester, OMNISCAM-1X automatic flaw detection, USN60 ultrasonic flaw detector, magnetic powder and non-destructive flaw detection etc,. The advanced inspection equipments and experimental methods provide guarantee for quality control and experiment on material, usability test and performance.

Professionals & Comprehensive Inspection

The factories of CNBM invested 2.3 billion RMB for large-scale

CNBM international Corporation has completed equipment and technology upgrade transformation, which was concentrated on three projects, production line of centrifugal casting rolls for hot strip and plate mill, forged roll for cold/hot strip mill, national class technology center and roll material lab. Through upgrade transformation, the following targets have been achideved:

(1)It becomes the world's biggest specialized mill roll maker with the largest production scale, the most complete specifications of products and the most extensive coverage of various rolls used on rolling mill.

(2) The technology of equipments has reached international leading level.

(3) "Mechanization, automation, intellectualization, digitization" of equipments obviously improve the quality control ability.

(4) New types of research instruments improve the R&D capacity of products.

Customers Visit

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your requirement.

- Q: What are the different types of finishing processes used in metal casting machinery?

- There are several types of finishing processes used in metal casting machinery, each serving a specific purpose to achieve the desired final product. Some of the common finishing processes include: 1. Grinding: This process involves the use of abrasive wheels or belts to remove excess material, smooth rough surfaces, and improve the dimensional accuracy of the cast metal parts. It is often used to remove casting defects such as burrs, flashes, or parting lines. 2. Sanding: Similar to grinding, sanding is performed using sandpaper or abrasive pads to smoothen the surface of the cast metal parts. It is commonly used to remove minor imperfections and prepare the surface for subsequent finishing processes like painting or plating. 3. Polishing: In this process, a polishing compound and a buffing wheel are used to create a smooth, shiny surface on the cast metal parts. Polishing is often performed after grinding or sanding to enhance the appearance and improve the surface finish. 4. Deburring: Casting processes can often result in the formation of sharp edges or burrs on the metal parts, which can be hazardous or interfere with their functionality. Deburring is the process of removing these unwanted edges or burrs using methods like manual filing, tumbling, or mechanical deburring machines. 5. Shot blasting: Shot blasting involves the use of high-speed projectiles, such as steel shots or grits, to clean the surface of cast metal parts. This process removes scale, rust, and other contaminants, improving the surface finish and preparing the parts for subsequent treatments like painting or plating. 6. Vibratory finishing: This process is commonly used to deburr, polish, or create a uniform surface finish on cast metal parts. It involves placing the parts in a vibratory bowl or tub, along with abrasive media, water, and compounds. The vibratory action causes the media to continuously contact the parts, resulting in desired finishing effects. 7. Coating: Coating processes, such as painting or plating, are used to enhance the appearance, protect against corrosion, or improve the performance of cast metal parts. Painting involves applying a protective layer of paint, while plating involves depositing a thin layer of metal onto the surface through electroplating or electroless plating techniques. These are just a few examples of the different finishing processes used in metal casting machinery. The choice of a specific process depends on factors such as the desired surface finish, part complexity, material type, and intended application of the cast metal parts.

- Q: What are the different types of molds used for die casting in metal casting machinery?

- There are several types of molds used for die casting in metal casting machinery, including permanent molds, semi-permanent molds, and expendable molds. Permanent molds are typically made from steel or iron and can be used repeatedly for multiple casting cycles. Semi-permanent molds are made from materials like sand or plaster and can be used for a limited number of casting cycles before they need to be replaced. Expendable molds, such as those made from sand or ceramic, are used for one-time casting and are destroyed to remove the casted part.

- Q: What are the different types of waste water treatment methods used in metal casting machinery?

- There are several different types of wastewater treatment methods that are commonly used in metal casting machinery to effectively manage and treat the wastewater generated during the casting process. These methods aim to remove various contaminants and impurities from the wastewater before it is discharged or reused. 1. Sedimentation: Sedimentation is a primary treatment method that involves allowing the wastewater to settle, allowing heavy particles and sediments to settle at the bottom of a tank. This method helps to remove larger particles and solids from the wastewater. 2. Filtration: Filtration is another common method used in metal casting wastewater treatment. It involves passing the wastewater through various filtration media such as sand filters, activated carbon filters, or membrane filters to remove suspended solids, organic matter, and other impurities. 3. Coagulation and Flocculation: Coagulation and flocculation are chemical treatment processes that involve adding chemical coagulants and flocculants to the wastewater. These chemicals help to agglomerate fine particles and colloidal suspensions, making them easier to remove through sedimentation or filtration. 4. Biological Treatment: Biological treatment methods like activated sludge process or sequencing batch reactors (SBR) are commonly used to treat wastewater in metal casting machinery. These methods utilize microbial organisms to break down organic matter and nutrients present in the wastewater, converting them into less harmful substances. 5. Chemical Precipitation: Chemical precipitation is a method used to remove heavy metals and other dissolved contaminants from the wastewater. It involves adding specific chemicals that react with the contaminants to form insoluble precipitates, which can then be separated from the treated water. 6. Advanced Oxidation Processes (AOP): AOPs involve the use of powerful oxidizing agents such as ozone, hydrogen peroxide, or ultraviolet (UV) light to degrade and remove organic pollutants from the wastewater. These processes are particularly effective in treating recalcitrant organic compounds. 7. Membrane Processes: Membrane processes, such as reverse osmosis (RO) and ultrafiltration (UF), are used to further purify the treated wastewater by removing dissolved solids, salts, and other contaminants. These processes utilize semi-permeable membranes that allow clean water to pass through while retaining the contaminants. It is important to note that the selection of wastewater treatment methods for metal casting machinery depends on factors such as the type of contaminants present, the volume of wastewater generated, the required treatment efficiency, and local regulatory requirements. Therefore, a combination of these treatment methods may be employed to achieve the desired level of wastewater quality before discharge or reuse.

- Q: Can metal casting machinery be used for producing large castings?

- Yes, metal casting machinery can be used for producing large castings.

- Q: What are the common molding materials used in investment casting with metal casting machinery?

- The common molding materials used in investment casting with metal casting machinery are ceramic shell and plaster. Ceramic shell is a mixture of fine ceramic particles and a binder, typically made from colloidal silica. This mixture is applied onto the wax pattern and then dried to form a hard and rigid shell. Ceramic shell molds offer excellent dimensional accuracy and surface finish. Plaster, or gypsum, is another common molding material used in investment casting. Plaster molds are created by immersing the wax pattern in a slurry of plaster and water, allowing it to harden. Plaster molds are known for their excellent heat resistance and can be easily customized or repaired. Both ceramic shell and plaster molds have their advantages and disadvantages. Ceramic shell molds are preferred for complex and intricate shapes as they can capture fine details, while plaster molds are more suitable for larger and simpler designs. Additionally, ceramic shell molds are more expensive and time-consuming to produce compared to plaster molds. Overall, the choice of molding material depends on the specific requirements of the casting process, such as the complexity of the design, desired surface finish, and budget constraints.

- Q: How is the casting inspected for visual appearance in metal casting machinery?

- In metal casting machinery, the inspection of the casting for visual appearance is a crucial step to ensure the quality and integrity of the final product. Various techniques and methods are employed to inspect the casting visually, allowing for the identification and assessment of any defects or imperfections. One commonly used method is visual inspection by a trained inspector. This involves visually examining the casting under adequate lighting conditions to assess its overall appearance. The inspector looks for any surface irregularities, such as cracks, porosity, shrinkage, or incomplete fillings, which may affect the structural integrity or functionality of the casting. Additionally, they check for any visual defects that may impact the aesthetic appeal of the finished product. To enhance the inspection process, magnifying tools like magnifying lenses or microscopes may be utilized. These tools enable inspectors to closely examine the casting's surface and identify any minute defects that might not be visible to the naked eye. This level of detail ensures that even the smallest imperfections are detected and addressed, ultimately improving the quality of the casting. Another technique used for visual inspection is the application of liquid penetrant testing. This method involves applying a liquid dye to the surface of the casting, which seeps into any surface defects or cracks. After a certain duration, the excess dye is removed, and a developer is applied, making the defects more visible. This method allows for the detection of even the tiniest cracks or imperfections that may not be easily visible with regular visual inspection. In some cases, advanced technologies like X-ray imaging or computerized tomography (CT) scans may be employed. X-ray imaging enables inspectors to look inside the casting and identify internal defects such as voids, inclusions, or misalignments. CT scans provide a detailed 3D image of the casting, allowing for a comprehensive analysis of its internal and external structures. Overall, the inspection of casting for visual appearance in metal casting machinery is a meticulous process involving trained inspectors, magnifying tools, liquid penetrant testing, and sometimes advanced technologies. By thoroughly examining the casting's surface and internal structures, any defects or imperfections can be identified and rectified, ensuring the production of high-quality castings that meet the desired visual standards.

- Q: What are the different types of casting defects that can occur in sand casting?

- Some of the common types of casting defects that can occur in sand casting include shrinkage defects, porosity, misruns, cold shuts, sand inclusion, and metal penetration.

- Q: What are the key considerations in upgrading metal casting machinery?

- The key considerations in upgrading metal casting machinery include assessing the current machinery's capabilities and limitations, identifying specific areas for improvement, evaluating the cost and feasibility of the upgrade, ensuring compatibility with existing processes and systems, and considering the potential impact on production efficiency and quality. Additionally, factors such as regulatory compliance, safety measures, and the availability of skilled operators should also be taken into account when planning the upgrade.

- Q: How does metal casting machinery handle the removal of finishes from castings?

- The elimination of finishes from castings is typically accomplished by metal casting machinery using a technique known as shot blasting. Shot blasting involves forcefully propelling high-speed projectiles, such as steel shot or grit, against the surface of the casting. These projectiles impact the casting's surface, effectively removing any finishes, coatings, or impurities that may be present. To initiate the shot blasting process, the castings are loaded onto a conveyor belt or into a shot blasting chamber. As the castings progress through the machine, a stream of projectiles propelled by centrifugal force or compressed air is directed towards them. These projectiles strike the castings with great force, dislodging any undesirable finishes or coatings that may be present. The choice of shot blasting machinery depends on the size and complexity of the castings. For smaller castings, a tumble blast machine may be utilized. In this machine, the castings are placed inside a rotating drum, and shot is continuously blasted onto them. Conversely, larger castings may necessitate the use of specialized shot blasting machines, such as spinner hangers or conveyor blast machines. These machines are capable of handling heavier and bulkier parts. Following the shot blasting process, the castings are thoroughly cleaned and devoid of any finishes or coatings that were previously applied. This prepares the castings for subsequent manufacturing operations, such as heat treatment, machining, or surface finishing. In conclusion, metal casting machinery effectively removes finishes from castings through the shot blasting process. This process provides an efficient and dependable method to ensure that castings are clean and ready for further manufacturing operations.

- Q: Can metal casting machinery produce castings with consistent quality?

- Yes, metal casting machinery can produce castings with consistent quality. Metal casting machinery is designed to meet strict quality control standards and ensure that each casting produced meets the specified requirements. The machinery is equipped with advanced technologies and automation systems that enable precise control over the casting process, including temperature, pressure, and cooling rates. This helps to minimize variations and defects in the castings, resulting in consistent quality. Additionally, the machinery is regularly maintained and calibrated to ensure its optimal performance, further enhancing the consistency of the castings produced. Quality control measures such as inspection and testing are also implemented throughout the casting process to identify any deviations and ensure that only castings meeting the desired quality standards are approved. Overall, metal casting machinery is capable of producing castings with consistent quality through its advanced technology, automation systems, and stringent quality control measures.

Send your message to us

Alloy Roll with High Wear Resistance and High Performance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches