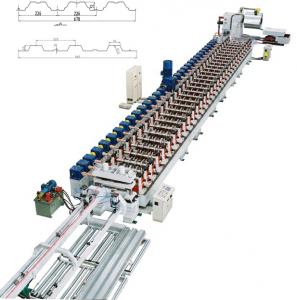

High performance of light steel keel rolling equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Keel machine is a strip as raw material, through the continuous cold rolling,cross section steel production complex (products: light steel keel, baking paint keel, keel cassette, a variety of architectural profiles, steel structure, steel lined door frame section, high-speed guardrail etc.) and cold, different specifications of the baking unit equipment, using PLC control.

Characteristics of keel machine:

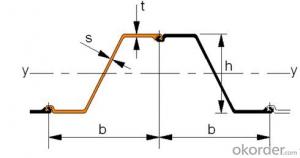

Rolling capacity of 1 units: width less than or equal to 150mm, the thickness of the plate 0.6-2.0mm

The 2 production speed: 6-13 M / min

3 total installed capacity: About 5.5kw

4 production area: 15 meters long and 2.5 meters wide X

The 1 device control to PLC control, set multiple safety protection during normal production.

2 bed for the steel plate welded parts. And tempering treatment to eliminate internal stress, deformation, avoid the fuselage.

3 forming machine frame is cast iron structure, and the tempering treatment.High strength, long service life.

4 roll material is 40Cr, and after quenching and tempering, the hardness of HB280.

5 mold material GCr15, quenching, hardness: HRC56-62 degrees.

6 for gear transmission structure. Each forming frame has light steel keel machine. Ensure the device over time, high strength and operation, and long service life.

The processing technology of keel machine: discharge ---- ---- ---- cut straightguide roll forming - receiving

Keel machine equipment composition: the feeding machine, a guide frame,forming machine, correction device, fixed length cutting part and a receiving platform and electric control part and so on.

Keel machine after the installation is in need of a debugging:

1 put the color steel keel machine equipment before and after the four horns and two queue from big frame exactly measure the height of the upper end of the shaft is favorable;

2 then from the first row to the last row, find a straightened wire, check whether under shaft in a straight line, the lower shaft left, right sides move into level,the light steel keel machine first and last row find good center;

3 then tighten both sides lock nut, pull a straight line in the center of the middlewheel is the before and after, the gap adjustment, the lower shaft well, canadjust machine down the line.

Light steel keel machine inspection and maintenance is very tedious anddangerous, we usually do not pay attention to it is easy to cause danger, last time we talk about the matters needing attention in using, today we look at thenote, usually on the light steel keel machine inspection and maintenance in the process of.

We said maintenance time is when the light steel keel machine is not running,when it is low season. When we want to carry out maintenance, we have to do is turn off the power first. Let it in a complete state of the power. At the same time, some conductive articles worn on body we also want to remove, andsafety gloves, must wear special goggles, long sleeved clothes and other protective articles. Do safety measures the biggest. If you to light steel keel machine do not know, you need to have more professional people to check and maintain. When found to have exposed joints in the outside, or other wirecutting and not from the elements, we can carry on the detailed record, after that, to a professional repair personnel to repair. For pressure joint inspection,we should advance the release of pressure, pressure supply pressure to zero,then the operation.

Light steel keel machine as machinery and equipment of modern, because ithas many excellent properties, in the field of application is very extensivehome. What equipment has its service life, should operate according to the instructions in the use of light steel keel machine, used also to do somemaintenance. This can not only improve the efficiency but also can extend the service life. So what to do to use light steel keel machine ready?

Must first check whether need to add oil, parts need cleaning, triangular keelmachine is loose or shift. In the course of the operation, there was nooccurrence of abnormal noise or other abnormal situations, if found this situation, must first stop check, after a period of use, lubricating oil should beadded in a timely manner, and cleaning need to clean parts. Do these, can have the efficiency, safety production, but also can improve the service life.

- Q: What is the roll forming machine?

- The mold base elliptical motion device comprises a mold base, a slider, a slider block, a mold plate, a fixing plate, an elliptical long shaft adjusting rod and a mold base, wherein the mold base is connected with the slider through the lower part,

- Q: How is the molding machine installed?

- Factory QTJ4-25 block forming machine have been in accordance with the relevant provisions of the factory have done the factory test, but due to long-distance transport and a long time to place and other reasons, the installation should be the following checks:

- Q: How to maintain the molding machine?

- 1 Check the host before driving is complete, than with loose and electrical loose, electrical grounding is good.

Send your message to us

High performance of light steel keel rolling equipment

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords