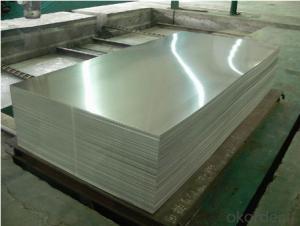

H14 H16 H18 5052 Flat Aluminum Roofing Sheets for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

H14 H16 H18 5052 aluminum plate for decoration

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

Product Description

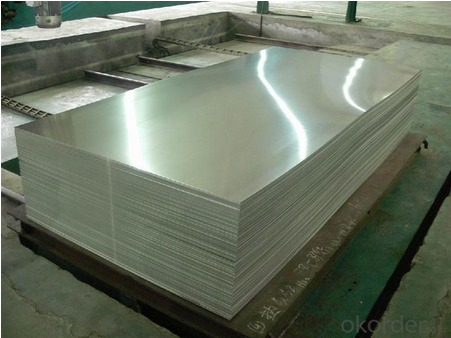

Goods name | Aluminum plate |

alloy | Yes |

Plance of origin | China |

Quality | Prime quality |

Certificate | ISO9001 |

Grade | 3000 Series |

Thickness | 0.3-150mm |

Type | Plate |

Width | 300-1950mm |

Model number | 3003,3004,3005,3014,3105 |

Surface | Mill finish |

Temper | O-H112 |

Ensure | we can supply customers' with different specifications of the highest quality and lowest price. Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit. |

- Q: What specific considerations or precautions should be taken into account when using aluminum sheets in environments with high moisture levels?

- <p>When using aluminum sheets in damp or wet environments, it's important to consider the potential for corrosion. While aluminum is generally corrosion-resistant due to its protective oxide layer, it can still be susceptible to certain types of corrosion in the presence of moisture, especially if the environment is acidic or saline. It's crucial to use high-quality aluminum alloys that are designed for such conditions. Additionally, proper surface treatment such as anodizing or applying protective coatings can enhance resistance to corrosion. Regular inspections and maintenance are also recommended to check for signs of corrosion and to address any issues promptly.</p>

- Q: Can 101 aluminum sheets be used in the production of decorative panels?

- Indeed, decorative panels can be produced with the use of 101 aluminum sheets. Recognized for its exceptional formability and resistance to corrosion, 101 aluminum stands out as a commercially pure alloy. This alloy's remarkable attributes render it appropriate for diverse applications, decorative panels being one of them. The aluminum sheets have the capacity to be effortlessly molded, trimmed, and crafted, enabling the formation of intricate designs and patterns for ornamental intentions. Furthermore, the corrosion resistance of 101 aluminum guarantees that the panels will retain their visual appeal throughout time, even when exposed to outdoor conditions or environments with high moisture levels.

- Q: Do 101 aluminum sheets have any specific insulation properties?

- No, 101 aluminum sheets do not have any specific insulation properties.

- Q: Can aluminum sheet be used for architectural applications?

- Aluminum sheet is indeed suitable for architectural purposes, thanks to its impressive strength, durability, and resistance to corrosion. It is widely utilized in the construction field for various architectural applications such as cladding, roofing, and facades. Architects and designers can select aluminum sheets in different thicknesses to meet their specific aesthetic and functional requirements. These sheets can be easily shaped, bent, and formed to create distinctive architectural elements like panels, screens, louvers, and decorative features. Moreover, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Techniques such as anodizing, powder coating, or painting can be employed to improve the material's resilience against weathering, UV radiation, and pollution. Due to its lightweight nature, aluminum is favored for architectural applications as it reduces the overall weight of the structure and facilitates convenient installation. Additionally, aluminum is an environmentally friendly option for architectural projects as it can be recycled infinitely, thus promoting sustainability. To summarize, aluminum sheets are a highly viable and popular choice for architectural purposes because of their strength, versatility, durability, and aesthetic appeal.

- Q: What is the hardness of aluminum sheets?

- The hardness of aluminum sheets can vary depending on the specific alloy and temper it has been processed to. Aluminum alloys are typically measured on the Rockwell hardness scale or the Brinell hardness scale. Generally, pure aluminum has a low hardness rating, around 20-30 on the Rockwell B scale, while some aluminum alloys can reach a hardness of up to 70 on the Rockwell C scale. However, it is important to note that the hardness of aluminum can be further modified through various heat treatment processes, such as annealing or tempering, which can significantly impact its final hardness.

- Q: I was looking at Audioque subs earlier and what is the difference between copper and aluminum coiled subs. do aluminum last longer or something?

- to maintain it common......Copper is better at removing or soaking up warmth than aluminum yet aluminum is better at dissipating it or doing away with it. i think it is why you spot aluminum CPU coolers with copper cores.

- Q: What are the different methods of cutting aluminum sheet?

- There are several methods of cutting aluminum sheet, each with its own advantages and applications. 1. Shearing: This is a straightforward method that involves using a sharp blade to cut through the aluminum sheet. It is a fast and efficient process, especially for straight cuts. However, it may not be suitable for complex or intricate designs. 2. Laser cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the aluminum sheet, resulting in a precise and clean cut. This method is ideal for intricate designs, as it allows for detailed and accurate cuts. Laser cutting is also fast and can be automated, making it suitable for large-scale production. 3. Waterjet cutting: Waterjet cutting involves using a high-pressure stream of water mixed with abrasive materials to cut through the aluminum sheet. This method is versatile and can handle different materials and thicknesses. It produces a smooth and precise cut without generating heat, making it suitable for heat-sensitive materials. 4. Plasma cutting: Plasma cutting involves using a plasma torch to heat and melt the aluminum sheet, creating a cut. It is a fast and cost-effective method, especially for thicker sheets. However, the cut might not be as clean compared to laser or waterjet cutting. 5. CNC milling: Computer Numerical Control (CNC) milling involves using a rotating cutting tool to remove material from the aluminum sheet, creating a cut. This method is precise and can produce complex shapes and designs. It is commonly used for prototypes or small production runs. It is important to consider factors such as the desired cut quality, complexity of the design, material thickness, and production volume when choosing the appropriate method for cutting aluminum sheet.

- Q: Can the aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a popular choice for marine applications due to its excellent corrosion resistance. Unlike other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, preventing further corrosion. This makes it ideal for use in saltwater environments where the risk of rusting and corrosion is high. Additionally, aluminum is lightweight, durable, and has a high strength-to-weight ratio, making it suitable for various marine applications such as boat hulls, shipbuilding, offshore platforms, and other marine structures.

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties and is known for its ability to withstand the harsh conditions found in marine environments. Unlike many other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from saltwater and other corrosive elements. Additionally, aluminum is lightweight yet strong, making it an ideal choice for marine applications where weight reduction is important. It is commonly used in the construction of boats, ships, offshore structures, and other marine equipment.

- Q: I don't know if the electrons are being passed from my hand to the aluminum or from the aluminum to my hand.Thanks

- Aluminum is a metal and a good conductor of electricity. If you touch it, it will get grounded, so it will be neutral. You cannot charge a metal up by touching it with your hand unless you are not grounded yourself. If you are standing on a piece of plastic, say, then it will take whatever charge is on you. If you are positive, it will become positive. If you are negative, it will become negative. But you must be insulated from ground to do that. If you are touching the ground then any charge on the aluminum will just flow out of the metal through you to ground and the aluminum will stay neutral

Send your message to us

H14 H16 H18 5052 Flat Aluminum Roofing Sheets for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords