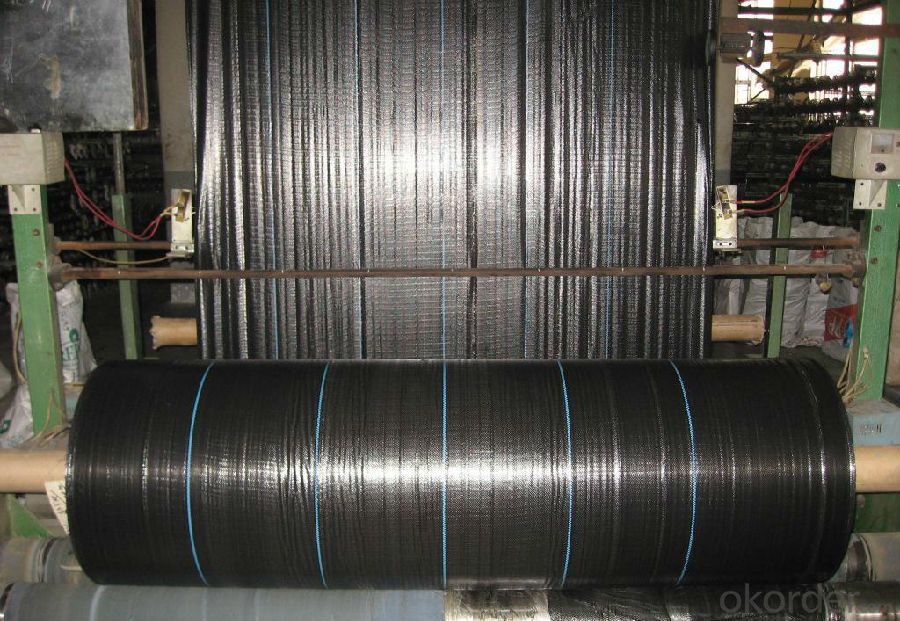

Capa Geotextil Groundcover for Agriculture/Landscape/Weed Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Woven Geotextile Introduction

Geotextiles are composed from synthetic polypropylene/polyester fibres through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration.

Type: 1. Wovens & knitted: use various fibre types in different combinations.

2. Non-wovens: staple or continuous fibres that are heat treated or needlepunched to “fix” fibres relative to each other.

Woven Geotextile Specification

1) Weight / Mass: 75g/m2-400g/m2 .

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP

5) Color: Black , white , grey, others

6) The biggest geotextile manufacturer/factory in China for many years . The equipment is introduced from Germany.

7) This geotextile can be made of polypropylene (PP).

8) The mass is available from 75g/m2 to 400g/m2 and the width available from 1.0m-8m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber.

9) Color: all kinds of color are available. The annual production ability is 10 million square meters.

Woven Geotextile Application

1) Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3 )Reinforcement:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 )Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles help with reinforcement of embankments?

- Geotextiles help with the reinforcement of embankments by providing stabilization and strength to the soil, preventing erosion and promoting proper drainage. They act as a barrier by separating different layers of soil, preventing the intermixing of fine and coarse particles. This enhances the overall stability of the embankment and increases its load-bearing capacity. Additionally, geotextiles help to distribute the applied loads more evenly, reducing the potential for differential settlement and ensuring long-term stability of the embankment.

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- That is, at home and home boundaries to break off. Or can not achieve the effect of waterproof

- Q: Geotextile mouth chain suture is what kind of picture

- Hello I am a professional geotextile and other geotextile materials,

- Q: River slope protection geotextile unit area quality is generally how much

- Geotextile width of 2-6 meters. Length can be customized according to the requirements, generally 100g - 1000g specifications, per square meter. I am specializing in the production of geotextile materials, welcome you, hope to adopt!

- Q: How do geotextiles help with soil stabilization in construction sites?

- Geotextiles help with soil stabilization in construction sites by providing reinforcement and separation between different soil layers. They act as a barrier, preventing the mixing of different soil layers, which helps maintain the stability and strength of the soil. Additionally, geotextiles distribute the load evenly across the construction site, reducing the potential for soil erosion and settling.

- Q: How are geotextiles used in shoreline protection?

- Geotextiles are used in shoreline protection to prevent erosion by stabilizing the soil and reducing wave energy. They are placed along the shoreline to act as a barrier, preventing sediment from being washed away and providing a stable foundation for vegetation to grow. Additionally, geotextiles can be used to filter water and trap sediment, improving water quality and protecting the shoreline from further degradation.

- Q: Water stable health with the geotextile, sticky on the water stable, how quickly cleared

- I professional production geomembrane / geotextile, the highest cost, I wish smooth

- Q: Geotextile use

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

- Q: Can geotextiles be used in geotechnical engineering?

- Yes, geotextiles can be used in geotechnical engineering. Geotextiles are permeable fabrics that can be used to enhance the performance and stability of soil in various geotechnical applications such as erosion control, soil reinforcement, filtration, drainage, and separation. They are commonly used in road construction, landfills, retaining walls, embankments, and other geotechnical structures. Geotextiles provide added strength, durability, and protection to the soil, making them an essential component in geotechnical engineering projects.

- Q: What are the standards and regulations governing geotextiles?

- Geotextiles are governed by various standards and regulations to ensure their quality, performance, and safety. Some of the key standards include ASTM D4355, which defines the classification system for geotextiles based on their functions and characteristics, and ASTM D4595, which specifies the test methods for determining the properties of geotextiles. Additionally, regulations such as the American Association of State Highway and Transportation Officials (AASHTO) and the Federal Highway Administration (FHWA) provide guidelines for the use of geotextiles in transportation projects. These standards and regulations aim to promote consistency, reliability, and effectiveness in the use of geotextiles for various applications.

Send your message to us

Capa Geotextil Groundcover for Agriculture/Landscape/Weed Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords