Geocells for Sale - Grass Protection Geogrids of Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

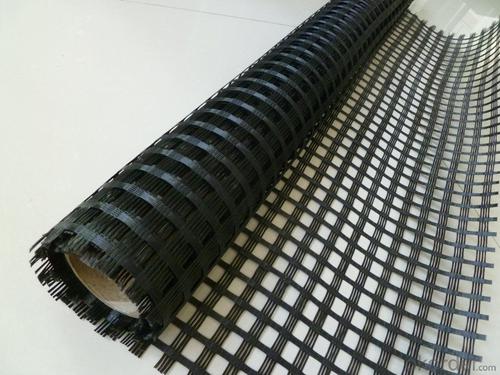

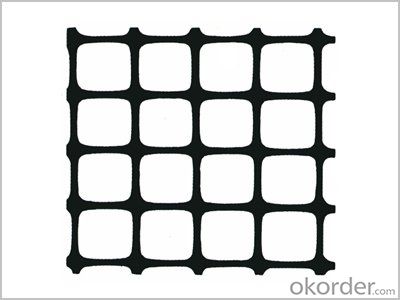

Our niaxial geogrids are made from polyester yarn, knitted or woven into a stable structure and have a PVC or polymeric coating. These flexible, user-friendly geogrids are inert to biological degradation and resistant to creep, strain and naturally found chemicals.

Unidirection-elongation plastic geogrid

The unidirection-elongation geogrid is a uniform-holed mesh from macromolecular polymer and subjected to elongation.This process enables the macromolecules to be in a directional and linear state,and assumes an elliptical integral structure with even distribution of macromolecules and high –strength nodes.This structure tends to have a considerable tensile strength and elongation modulus(elongation at 2% to 5%)that exceeds international standards.This provides soil with and idea interlocking system for load capacity and dispersion on the soil.The product has a tensile strength of over 150Mpa,hence is suitable for all types of soil and is now wildely used as reinforcement material.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geogrids suitable for use in cold climates?

- Yes, geogrids are suitable for use in cold climates. Geogrids are designed to withstand extreme weather conditions, including cold temperatures. They are made from materials that can resist freezing and maintain their structural integrity in cold environments. Additionally, geogrids are used for reinforcement and stabilization purposes in civil engineering projects, such as roads and retaining walls, in various climates worldwide, including cold regions.

- Q: How much is the tensile strength of geogrid???????

- Divided into three categories: the overall plastic stretch: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: Can geogrids be used in reinforcement of reinforced soil slopes?

- Yes, geogrids can be used in the reinforcement of reinforced soil slopes. Geogrids are commonly employed in these applications to enhance the stability and strength of the soil by providing tensile reinforcement. They are effective in preventing slope failures and soil erosion, making them a valuable tool in the reinforcement of reinforced soil slopes.

- Q: The cheapest two-way plastic geogrid manufacturers, two-way plastic geogrid prices?

- Its elongation rate is only 10% ~ ~ of the original plate of 15%. If the carbon black and other anti-aging materials are added in the geogrid, the utility model has the advantages of good acid resistance, alkali resistance, corrosion resistance, aging resistance and the like.

- Q: Product features: high strength, small deformation; creep; corrosion resistance, long service life: steel plastic geogrid with plastic material as a protective layer, which is supplemented with a variety of additives in aging resistance, oxidation resistance, corrosion resistance to acid and alkali, salt and other harsh environment

- What dialect! Is Chinese

- Q: How do geogrids help in reducing the risk of differential settlement of structures?

- Geogrids help in reducing the risk of differential settlement of structures by providing reinforcement and stability to the soil. They distribute the load over a larger area, preventing localized settlement and ensuring a more uniform settlement across the structure. This helps to maintain the integrity and stability of the structure, reducing the risk of differential settlement and potential damage.

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners?

- Yes, geogrids can provide reinforcement to geosynthetic asphalt liners. Geogrids are typically used to enhance the stability, strength, and performance of geosynthetic materials, including asphalt liners. They help distribute loads and reduce stress, improving the overall durability and longevity of the liner system.

- Q: What is the meaning of 400g geotextiles /100g woven fabric

- Main production, geotextile, geogrid, geomembrane

- Q: The geogrid is convenient for construction, time saving, labor saving, shorten the construction period and reduce maintenance cost.

- Fill enough paint to make it smooth.6, removal of leakage of tape. Then, note that all of the cracks have been properly repaired, with a fine composite material will be modified around the repair, so that it is as bright as new.

- Q: What are the factors to consider in selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, several factors need to be considered. These factors include the required strength and durability of the geogrid, the type and condition of the soil being reinforced, the anticipated load or traffic on the geogrid, the climate and environmental conditions of the project site, and the cost-effectiveness of the geogrid. Additionally, factors such as installation requirements, compatibility with other materials, and the availability of the geogrid in the required dimensions and specifications should also be taken into account.

Send your message to us

Geocells for Sale - Grass Protection Geogrids of Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords