Grade AISI 4140 _42CrMo4 Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI 4140 _42CrMo4 Steel Round Bar

Details of Grade AISI 4140 _42CrMo4 Steel Round Bar

Name | Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of Grade AISI 4140 _42CrMo4 Steel Round Bar

1.Size of 4140 Steel Round Bar | ||||||||

Round bar | Diameter(mm) | Length (mm) | ||||||

20~800 | 3000~9000 | |||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | |||||

Max:800 | Max:2200 | Max:9000 | ||||||

The specification can be customized. | ||||||||

2.Chemical Compositons | ||||||||

Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

42CrMo | 0.38~0.45 | 0.17~0.37 | 0.50~0.8 | ≤0.035 | ≤0.035 | 0.9~1.2 | 0.15-0.25 | ≤0.3 |

4140 | 0.40~0.45 | 0.15~0.35 | 0.75~1.0 | ≤0.035 | ≤0.040 | 0.8~1.1 | 0.15-0.25 | - |

SCM44 | 0.38~0.43 | 0.15~0.35 | 0.60~0.9 | ≤0.030 | ≤0.030 | 0.9~1.2 | 0.15-0.30 | ≤0.25 |

1.7225 | 0.38~0.45 | ≤0.40 | 0.60~0.9 | ≤0.025 | ≤0.035 | 0.9~1.2 | 0.15-0.30 |

|

3.Features of 4140 alloy steel | ||||||||

1. Chromium molybdenum alloy steel | ||||||||

2. Slightly higher carbon content then 4130 | ||||||||

3. Greater strength and heat treatment | ||||||||

4.Typical Applications | ||||||||

1. Applications in the oil and gas sector | ||||||||

2. Connection rods, collets, conveyor pins, | ||||||||

3. Gears, stem assemblies, | ||||||||

4. Pump shafts and tool holders | ||||||||

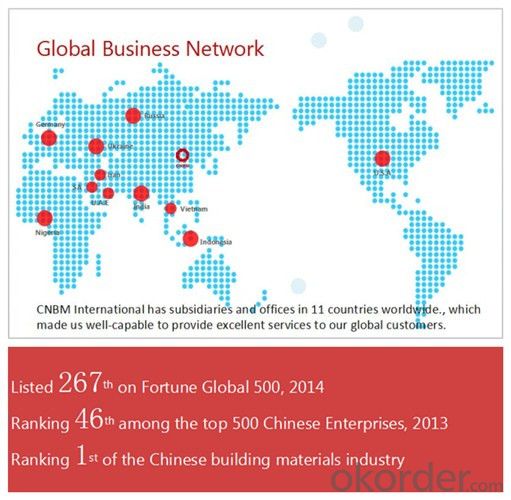

CNBM Introduction of Grade AISI 4140 _42CrMo4 Steel Round Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Grade AISI 4140 _42CrMo4 Steel Round Bar

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to improving product efficiency?

- Special steel contributes to improving product efficiency in several ways. Firstly, special steel typically has superior strength, durability, and corrosion resistance compared to regular steel. This allows manufacturers to design and produce products that can withstand higher loads, operate under harsh conditions, and have a longer lifespan. Secondly, special steel often has specific properties such as heat resistance or magnetic properties, which can be utilized in various industries like aerospace, automotive, and electronics. These properties enable the creation of more efficient and advanced products, such as high-performance engines, lightweight structures, or specialized electrical components. Additionally, special steel can be tailored to specific manufacturing processes, resulting in improved precision and productivity. Overall, the use of special steel enables the development of higher-quality, more reliable, and efficient products across multiple industries.

- Q: What are the different automotive grades of special steel?

- There are several different automotive grades of special steel used in the automotive industry. These grades are specifically designed to meet the unique requirements and demands of the automotive sector. Some of the commonly used grades include: 1. Advanced High-Strength Steels (AHSS): These grades of steel are known for their exceptional strength and excellent formability. AHSS is used in critical automotive components like chassis, body panels, and safety systems to enhance crash performance while reducing weight. 2. Dual-Phase Steels (DP): DP steels are a type of AHSS that offer a combination of high strength and good ductility. They are commonly used in automotive applications that require both strength and formability, such as structural components and reinforcements. 3. Martensitic Steels: These steels are known for their high strength and hardness. They are often used in automotive applications that require resistance to wear and impact, such as crankshafts, gears, and axles. 4. Transformation-Induced Plasticity (TRIP) Steels: TRIP steels are designed to provide high strength, good formability, and excellent energy absorption during impact. They are utilized in automotive safety components like bumper reinforcements and crash boxes. 5. High-Strength Low-Alloy (HSLA) Steels: HSLA steels offer a balance between strength, formability, and cost-effectiveness. They are commonly used in automotive structural components and suspension systems to reduce weight while maintaining structural integrity. 6. Stainless Steels: Stainless steels are corrosion-resistant and are used in automotive applications that require resistance to rust and corrosion, such as exhaust systems, fuel tanks, and decorative trims. These different grades of special steel provide automotive manufacturers with a wide range of options to meet specific needs in terms of strength, formability, durability, and corrosion resistance. The selection of the appropriate grade depends on the intended application and the desired performance characteristics.

- Q: How is alloy steel used in the production of gears and shafts?

- Alloy steel is commonly used in the production of gears and shafts due to its excellent combination of strength, durability, and resistance to wear and corrosion. The alloying elements such as manganese, chromium, nickel, and molybdenum enhance the properties of the steel, making it suitable for high-stress applications. The use of alloy steel in gears and shafts ensures their ability to withstand heavy loads, transmit power efficiently, and maintain dimensional stability under extreme operating conditions, thus increasing the overall lifespan and performance of the components.

- Q: How is nitrogen alloyed steel used in the production of high-strength bolts?

- Nitrogen alloyed steel is used in the production of high-strength bolts to enhance their mechanical properties. By adding nitrogen as an alloying element, the steel becomes stronger, more resistant to corrosion, and exhibits improved toughness. This makes the bolts suitable for applications requiring high levels of strength and durability, such as in construction, automotive, and aerospace industries.

- Q: Classification of special steel products

- Carbon structural steels are normally used directly under heat supply without heat treatment. The mass fraction of Q195, Q215, Q235 are usually of low carbon steel, good welding performance, good plasticity and toughness, a certain strength, often rolled into a sheet, steel, welded steel pipe, used for bridges, buildings and general manufacturing rivet, screw and nut parts etc.. Q255 and Q275 mass fraction of carbon steel is slightly high, high strength, good plasticity and toughness, can be welded steel, steel rolling, usually forming and plate structure and simple manufacturing machinery, connecting rod, gear coupling, pins and other parts. Plain carbon steel high carbon steel is basically contains alloy elements, the carbon content in the range of 0.65% ~ 1.35%, the production of low cost, easy to obtain raw materials, good machinability, after treatment can obtain high hardness and high wear resistance, so the steel is widely used to manufacture various. Cutting tool, mold, measuring tools.But the red hardness difference of this kind of steel, that is, when the working temperature is greater than 250 degrees, the hardness and wear resistance of steel will decline rapidly, and lose their ability to work. In addition, if carbon tools steel is made into larger parts, it is difficult to harden, and deformation and crack are easy to occur. This kind of steel must ensure both chemical composition and mechanical properties. The number is two digits by the average mass fraction of carbon steel in the 000 fraction (W C * 10000). For example, steel 45 shows the average mass fraction of carbon in steel is 0.45%; 08 steel indicates the average mass fraction of carbon in steel is 0.08%.

- Q: What are the limitations of special steel?

- Some limitations of special steel include its high cost and limited availability, as well as the difficulty in shaping and processing it. Additionally, special steel may have lower tensile strength compared to other materials and can be prone to corrosion if not properly maintained.

- Q: What are the properties of heat-resistant steel?

- Heat-resistant steel has several key properties that make it suitable for use in high-temperature environments. Firstly, it has a high melting point, allowing it to withstand extreme heat without deforming or melting. Additionally, it exhibits excellent strength and toughness at elevated temperatures, enabling it to maintain structural integrity under thermal stress. Heat-resistant steel also possesses good oxidation and corrosion resistance, preventing it from corroding or deteriorating when exposed to oxygen or other corrosive elements at high temperatures. Finally, it has low thermal expansion, ensuring dimensional stability even when subjected to significant temperature changes. Overall, the properties of heat-resistant steel make it a reliable choice for applications in industries such as aerospace, power generation, and petrochemicals, where it can endure and perform consistently under intense heat conditions.

- Q: Can special steel be used in the beverage manufacturing industry?

- Yes, special steel can be used in the beverage manufacturing industry. Special steel, such as stainless steel, is often preferred due to its corrosion resistance, hygienic properties, and durability. It is commonly used in various components of beverage production equipment, including tanks, pipes, valves, and fittings, to ensure the integrity and quality of the final product.

- Q: What are the main characteristics of tool steel?

- Tool steel is a type of steel that possesses several key characteristics, including high hardness, wear resistance, toughness, and heat resistance. It is specifically designed to be used in the production of tools and dies, where it needs to withstand intense pressure, abrasion, and high temperatures. Additionally, tool steel has the ability to retain its shape and sharpness even under heavy use, making it highly durable and reliable for various industrial applications.

- Q: What are the requirements for special steel used in marine applications?

- In order to ensure durability and performance in harsh marine environments, special steel used in marine applications must satisfy various specific criteria. These criteria encompass the following: 1. Corrosion resistance: To prevent degradation and maintain its structural integrity over time, special steel utilized in marine applications must possess a high resistance to corrosion, as it is exposed to saltwater in marine environments. 2. Strength and toughness: Steel employed in marine applications must exhibit adequate strength and toughness to withstand the dynamic forces and impacts encountered at sea. It must be capable of enduring heavy loads, extreme temperatures, and the impact of waves or collisions. 3. Weldability: Optimal weldability is a requirement for special steel used in marine applications, as it facilitates the construction and repair of marine structures. This characteristic ensures that the steel can be effortlessly joined without compromising its structural integrity. 4. Fatigue resistance: Special steel employed in marine applications must possess exceptional fatigue resistance to withstand the constant cyclic loading associated with wave motions, currents, and operational conditions. Failure to address this requirement can result in fatigue failure. 5. Low-temperature toughness: Due to the involvement of marine applications in cold climates or icy waters, special steel used in these scenarios must maintain its toughness and ductility even at low temperatures. This characteristic is pivotal in preventing brittle fracture and ensuring safety. 6. Fire resistance: High fire resistance is of utmost importance in marine applications. Therefore, special steel utilized in marine structures should possess a high level of fire resistance to prevent structural collapse and restrict the spread of fire. 7. Easy maintenance: Ongoing exposure to harsh environmental conditions necessitates that special steel used in marine applications be easy to maintain and repair. This ensures prolonged performance and minimizes downtime. To fulfill these requirements, special steel for marine applications frequently undergoes alloying with specific elements such as chromium, nickel, and molybdenum. This enhances corrosion resistance, strength, and toughness. Furthermore, advanced manufacturing processes and quality control measures are implemented to guarantee the highest standards of quality and performance in marine applications.

Send your message to us

Grade AISI 4140 _42CrMo4 Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords