Grade 309_316_316L Stainless Steel Flat Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grade 309_316_316LStainless Steel Flat Bar with High Quality

Details of Grade 309_316_316L Stainless Steel Flat Bar with High Quality

Name | 200,300,400 series Stainless Steel Flat Bar |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | 201/304/304L/309L/316/321 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 3mm-12mm |

steel flat bar width | 19mm-140mm |

steel flat bar length | 2m~6m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Chemical Composition of Grade 309_316_316L Stainless Steel Flat Bar with High Quality

Grade and Main chemical composition% | |||||||||

| C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | Other |

201 | ≤0.15 | ≤1.00 | 5.5-7.5 | 0.06 | 0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

304 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 8-10.5 | - |

304L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 13-Sep | - |

309S | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 22-24 | - | 15-Dec | - |

316 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 3-Feb | 14-Oct | - |

321 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | - | 13-Sep | Ti≥5×C |

CNBM Introduction of Grade 309_316_316L Stainless Steel Flat Bar with High Quality

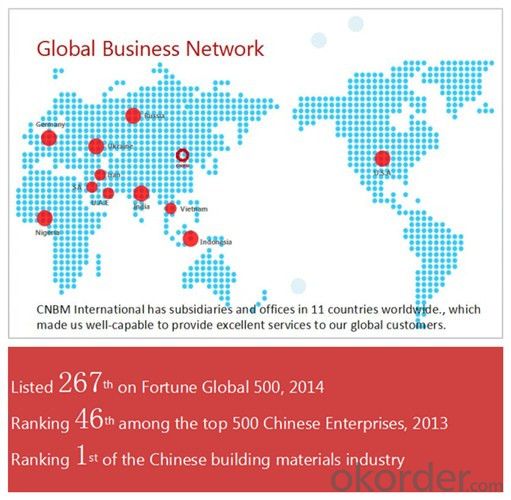

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of Grade 309_316_316L Stainless Steel Flat Bar with High Quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How do steel flat bars withstand heavy loads?

- Steel flat bars are specifically designed to withstand heavy loads due to their unique properties and construction. Firstly, steel is an incredibly strong and durable material. It has a high tensile strength, meaning it can withstand large amounts of force or pressure without breaking or deforming. This inherent strength makes steel flat bars an ideal choice for supporting heavy loads. Additionally, the flat shape of the bars provides increased stability and load-bearing capacity. The wide surface area of the flat bar allows for even distribution of the load, preventing concentrated stress points that could cause failure or deformation. Moreover, steel flat bars are often reinforced or tempered through various manufacturing processes. For example, they may be hot-rolled, which involves heating the steel to high temperatures and then rapidly cooling it to increase its strength and hardness. This process helps to further enhance the load-bearing capabilities of the flat bars. Furthermore, steel flat bars can be fabricated to meet specific load requirements. They can be cut, bent, or welded to create customized shapes and sizes that are optimized for the intended load. This versatility allows for the creation of structural elements that are specifically engineered to withstand heavy loads. Overall, the combination of steel's inherent strength, the wide surface area of the flat shape, reinforcement processes, and customization options make steel flat bars highly capable of withstanding heavy loads. They are a reliable and commonly used choice in construction, manufacturing, and other industries where robust load-bearing capabilities are necessary.

- Q: What are the different types of surface defects in copper steel flat bars?

- Some of the different types of surface defects in copper steel flat bars include scratches, dents, pits, scale, and oxidation.

- Q: Are steel flat bars suitable for high-traffic areas?

- Yes, steel flat bars are suitable for high-traffic areas. Due to their durability and strength, steel flat bars can withstand heavy foot traffic and the constant movement of people without getting easily damaged or worn out. They are resistant to impact and can handle the weight and pressure exerted by individuals walking or running on them. Additionally, steel flat bars are commonly used in industrial and commercial settings precisely because they are designed to withstand high traffic and heavy loads. Their sturdy construction and ability to handle constant use make them an ideal choice for areas such as walkways, staircases, platforms, and other high-traffic zones.

- Q: Can steel flat bars be used for manufacturing automotive parts?

- Yes, steel flat bars can be used for manufacturing automotive parts. Steel is a strong and durable material that is commonly used in the automotive industry. Flat bars made of steel can be easily shaped, welded, and manipulated to create various automotive components such as brackets, supports, frames, and reinforcement structures. These parts require strength, rigidity, and resistance to impact and wear, which are all characteristics of steel. Additionally, steel flat bars offer excellent mechanical properties, including high tensile strength and good ductility, making them suitable for withstanding the challenging conditions and loads experienced by automotive parts. Overall, steel flat bars are a versatile and reliable choice for manufacturing automotive components.

- Q: Can steel flat bars be used for making support beams or columns?

- Yes, steel flat bars can be used for making support beams or columns. Steel flat bars are versatile construction materials that are commonly used in various structural applications, including support beams and columns. They possess excellent strength and durability properties, making them suitable for bearing heavy loads and providing structural stability. Steel flat bars can be easily fabricated and welded to form the desired shape and dimensions required for support beams and columns. Additionally, their uniformity and consistent dimensions make them ideal for ensuring structural integrity in construction projects. Overall, steel flat bars are a reliable and widely used choice for making support beams and columns due to their strength, durability, and ease of fabrication.

- Q: Can steel flat bars be used as a base for mounting equipment or components?

- Yes, steel flat bars can be used as a base for mounting equipment or components. Steel flat bars are commonly used in construction and engineering projects due to their strength and durability. They provide a stable and sturdy foundation for mounting heavy equipment or components. Additionally, steel flat bars can be easily welded or bolted together to create custom mounting solutions. Their versatility and load-bearing capabilities make them suitable for a wide range of applications, including industrial machinery, electrical panels, and shelving systems.

- Q: What are the different heat treatment processes for steel flat bars?

- Steel flat bars can undergo different heat treatment processes to enhance their mechanical properties and overall performance. Some commonly used processes for steel flat bars include: 1. Annealing: By heating the steel flat bar to a specific temperature and slowly cooling it to room temperature, internal stresses are relieved, ductility is increased, and machinability is improved. 2. Normalizing: This process involves heating the steel flat bar above its critical range and allowing it to cool in air. Normalizing refines the grain structure, improves mechanical properties, and enhances overall toughness. 3. Quenching and tempering: In this two-step process, the steel flat bar is rapidly cooled in a liquid medium, such as oil or water, to achieve high hardness. This is followed by reheating the quenched steel to a lower temperature to reduce brittleness and improve toughness. 4. Case hardening: Also known as carburizing, this process involves heating the steel flat bar in a carbon-rich environment to add carbon to the surface. Case hardening creates a hard outer layer while maintaining a softer and more ductile core, enhancing wear resistance and providing a tough surface. 5. Stress relieving: This process is used to reduce residual stresses in the steel flat bar that may have accumulated during manufacturing or other processes. By heating the steel to a specific temperature and allowing it to cool slowly, stress relieving minimizes distortion and improves dimensional stability. These heat treatment processes can be customized to meet specific requirements and desired mechanical properties, making steel flat bars suitable for various applications in different industries.

- Q: Are steel flat bars resistant to wear or abrasion?

- Yes, steel flat bars are generally resistant to wear or abrasion. Steel is a durable and strong material that can withstand heavy loads and harsh conditions. The flat shape of these bars also helps distribute weight evenly, further enhancing their resistance to wear and abrasion. Additionally, steel can be hardened and treated to increase its wear resistance, making it even more suitable for applications where wear or abrasion is a concern. Overall, steel flat bars are a reliable choice when looking for a material that can withstand wear and abrasion.

- Q: What are the cost implications of using steel flat bars compared to other materials?

- The cost implications of utilizing steel flat bars in comparison to alternative materials can vary based on several factors. First and foremost, it is necessary to consider the cost of the steel flat bars themselves. Steel is a commonly used and readily available material, which often results in greater cost efficiency when compared to materials like aluminum or titanium. Additionally, steel flat bars can be manufactured in large quantities, leading to economies of scale and lower production costs. Furthermore, steel is renowned for its durability and strength, making it a favored choice in industries such as construction and manufacturing. Its high tensile strength enables the usage of thinner and lighter flat bars, ultimately reducing material costs. Steel also exhibits a high resistance to corrosion, thereby extending the lifespan of the product and reducing long-term maintenance and replacement expenses. However, it is crucial to consider additional costs associated with steel flat bars. For instance, steel possesses a higher density compared to alternatives like aluminum, which can result in increased transportation and handling costs due to its weight. Additionally, steel requires surface treatments or coatings to protect against rust, which may incur additional expenses. In contrast, other materials such as aluminum or titanium may have higher initial costs due to their scarcity or more intricate manufacturing processes. Nevertheless, these materials may offer advantages such as lighter weight, corrosion resistance, or specific mechanical properties that can justify their higher cost for certain applications. To summarize, the cost implications of utilizing steel flat bars in comparison to alternative materials depend on factors such as the initial material cost, durability, maintenance, transportation, and specific project requirements. It is essential to thoroughly evaluate the specific needs and priorities of the application to determine the most cost-effective option.

- Q: What are the different methods of cutting steel flat bars?

- There are several different methods of cutting steel flat bars, each with its own advantages and applications. 1. Sawing: One of the most common methods of cutting steel flat bars is using a saw. There are several types of saws that can be used, including band saws, circular saws, and abrasive saws. Band saws are ideal for cutting larger quantities of steel bars quickly and efficiently, while circular saws are more suitable for smaller jobs or cutting through thicker bars. Abrasive saws, also known as cutoff saws, use a rotating abrasive disc to cut through the steel. 2. Shearing: Shearing is another popular method for cutting steel flat bars. It involves using a shear machine that applies a significant amount of force to cut through the material. Shearing is particularly useful for cutting through thick steel bars, as the force applied allows for a clean, straight cut. 3. Plasma cutting: Plasma cutting is a more advanced method that uses a high-velocity jet of ionized gas to melt and cut through the steel. This method is highly precise and allows for intricate shapes and designs to be cut, making it suitable for more complex cutting requirements. 4. Laser cutting: Similar to plasma cutting, laser cutting utilizes a high-powered laser beam to melt and cut through the steel. This method is incredibly accurate and can produce clean, smooth cuts. Laser cutting is often used for cutting thin steel flat bars or for precise, intricate designs. 5. Waterjet cutting: Waterjet cutting utilizes a high-pressure jet of water mixed with abrasive particles to cut through the steel. This method is versatile and can cut through a wide range of materials, including steel. It is particularly useful for cutting through thicker steel bars or for materials that may be sensitive to heat. Overall, the choice of cutting method depends on factors such as the thickness of the steel, the desired precision, and the complexity of the design. Each method has its own advantages and limitations, so it is important to consider these factors when selecting the appropriate cutting method for steel flat bars.

Send your message to us

Grade 309_316_316L Stainless Steel Flat Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords