Gpc143041 Hot Rolled Aluminum Coils for Oil Tanker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Hot Rolled Aluminum Coils for Oil Tanker

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Hot Rolled Aluminum Coils for Oil Tanker

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Hot Rolled Aluminum Coils for Oil Tanker

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

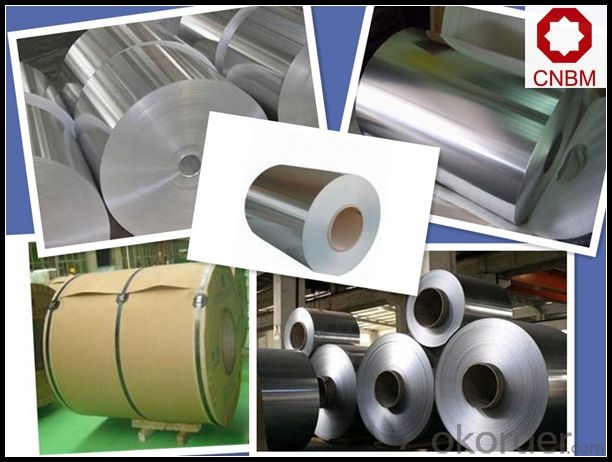

5. Image of Hot Rolled Aluminum Coils for Oil Tanker

6. Package and shipping of Hot Rolled Aluminum Coils for Oil Tanker

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the typical delivery options for aluminum coils?

- Delivery options for aluminum coils can vary depending on the supplier and customer's requirements. However, there are several common options available. 1. Direct delivery: Many suppliers offer the convenience of delivering the coils directly to the customer's location. This is particularly useful for customers who need large quantities or have limited transportation capabilities. The supplier will make arrangements for transportation, using trucks or shipping containers, to deliver the coils directly to the customer's facility. 2. Pickup from supplier: Customers also have the choice of arranging their own transportation and collecting the aluminum coils from the supplier's location. This option is often preferred by customers who are located nearby or already have their own transportation logistics in place. 3. Third-party logistics (3PL): Some suppliers collaborate with specialized logistics companies to handle the delivery of aluminum coils. These companies have expertise in transportation and offer efficient and cost-effective delivery services. Customers who prefer to outsource their logistics operations often choose this option. 4. International shipping: Customers requiring international delivery of aluminum coils have the option of using air or ocean freight. However, these methods may involve additional costs and longer delivery times due to customs clearance and transportation logistics. It's important to note that the specific delivery options may vary depending on the supplier's capabilities and the customer's location. Therefore, it is recommended to directly discuss delivery options with the supplier to ensure the most suitable and cost-effective method is chosen.

- Q: What is the maximum width of aluminum coils?

- The maximum width of aluminum coils can vary depending on various factors such as the manufacturing process, the specific grade and type of aluminum, and the capabilities of the equipment being used. However, in general, aluminum coils can have a maximum width ranging from a few inches to several feet. Industrial coil lines can typically handle widths up to 72 inches, while specialized equipment may be able to accommodate even wider coils. It is important to consult with the manufacturer or supplier to determine the specific maximum width available for a particular application.

- Q: Can aluminum coils be painted?

- Indeed, it is possible to paint aluminum coils. By applying paint to aluminum coils, an extra layer of protection against corrosion can be achieved, along with an improvement in their aesthetic appearance. Nevertheless, it is crucial to properly prepare the surface prior to painting in order to ensure a strong adhesion and durability. This typically involves a thorough cleaning of the coils, the removal of any existing paint or coatings, and the application of a primer specifically designed for aluminum surfaces. Once the primer has dried, a suitable paint can be applied using a brush, roller, or spray. For optimal and long-lasting results, it is advisable to use a high-quality paint specially formulated for metal surfaces. Additionally, following the instructions provided by the manufacturer and taking into account any environmental factors, such as temperature and humidity, that could impact the painting process, is of utmost importance.

- Q: How are aluminum coils protected against UV degradation?

- Aluminum coils are commonly protected against UV degradation through the application of protective coatings or treatments. These coatings act as a barrier between the aluminum surface and the harmful ultraviolet (UV) rays from the sun, preventing them from causing damage or degradation to the metal. One common method of protection is the application of organic coatings, such as polyvinylidene fluoride (PVDF) or polyester coatings. These coatings are specifically formulated to provide excellent resistance against UV radiation. They form a durable and protective layer on the surface of the aluminum coil, shielding it from the harmful effects of prolonged sun exposure. Another method is anodizing, which involves an electrochemical process that creates a protective oxide layer on the aluminum surface. This oxide layer acts as a barrier against UV rays and prevents them from reaching the underlying metal. Anodized aluminum coils are known for their excellent resistance to UV degradation and are commonly used in outdoor applications where long-term durability is required. In addition to these protective coatings and treatments, aluminum coils can also be designed with specific alloy compositions that enhance their resistance to UV degradation. Certain alloy elements, such as magnesium and manganese, can improve the natural ability of aluminum to withstand UV radiation. These alloy additions increase the overall durability and UV resistance of the aluminum coil, minimizing the potential for degradation over time. Overall, the protection of aluminum coils against UV degradation is a critical consideration in applications where the coils are exposed to sunlight. By utilizing protective coatings, anodizing, or selecting appropriate alloy compositions, manufacturers can effectively safeguard the aluminum coils and ensure their long-term performance and durability even in challenging outdoor environments.

- Q: Are aluminum coils easy to install?

- Yes, aluminum coils are generally easy to install. They are lightweight and flexible, which makes them easier to handle and maneuver during installation. They can be easily cut and shaped to fit the specific requirements of the installation, and they are often available in pre-cut sizes, further simplifying the installation process. Additionally, aluminum coils are typically designed with features such as interlocking edges or snap-on connectors, which make it easier to join multiple coils together or connect them to other components. Overall, with the right tools and basic knowledge of HVAC installation, aluminum coils can be installed relatively easily.

- Q: What are the recognized standards that dictate the quality of aluminum coil?

- <p>Yes, there are several standards that define the quality of aluminum coil. These include ASTM B209, which specifies requirements for aluminum and aluminum alloy flat sheet, coil, and plate for general usage. ASTM B210 covers aluminum and aluminum alloy sheet and plate for heat-treating. Additionally, EN 485 is a European standard that specifies the requirements for aluminum and aluminum alloy cold-rolled sheets, strips, and plates. These standards outline dimensions, chemical composition, mechanical properties, and other quality aspects to ensure the material meets industry requirements.</p>

- Q: What are the potential applications of perforated aluminum coils?

- Perforated aluminum coils offer a wide range of potential applications due to their unique characteristics and versatility. Here are some of the potential uses of perforated aluminum coils: 1. Architectural applications: Perforated aluminum coils can be used in architectural projects for facades, sunscreens, and cladding systems. The perforations can create aesthetically pleasing designs while also providing ventilation and sun control. 2. Filtration systems: The perforated holes in aluminum coils allow them to be used as filters for various applications. They can be utilized in air, liquid, or gas filtration systems, ensuring the removal of contaminants while maintaining an efficient flow. 3. Industrial equipment: Perforated aluminum coils can be incorporated into industrial equipment such as heat exchangers, condensers, and evaporators. The perforations aid in heat transfer, promoting efficient cooling or heating processes. 4. Automotive industry: The lightweight and durable nature of perforated aluminum coils make them suitable for the automotive industry. They can be used in the manufacturing of automobile parts like grilles, radiator covers, and engine components, providing both functionality and aesthetic appeal. 5. Acoustic panels: The perforations in aluminum coils can help in sound absorption and noise reduction. They can be used in the construction of acoustic panels for auditoriums, theaters, recording studios, and other spaces where sound quality is crucial. 6. Decorative applications: Perforated aluminum coils can be utilized for decorative purposes in interior design projects. They can be shaped into screens, room dividers, or wall panels, creating visually appealing patterns and adding a touch of modernity to spaces. 7. Agricultural applications: Perforated aluminum coils can find applications in the agricultural sector. They can be used in crop protection systems, allowing for controlled air circulation while protecting plants from pests or excessive sunlight. 8. Energy-efficient solutions: The perforations in aluminum coils can be beneficial for energy-efficient applications. They can be incorporated into solar panels, allowing light to pass through while maintaining structural integrity. Overall, perforated aluminum coils offer a wide range of potential applications across various industries, including architecture, filtration, industrial equipment, automotive, acoustic panels, decorative projects, agriculture, and energy-efficient solutions. The versatility, lightweight, durability, and aesthetic appeal of these coils make them a popular choice for many different uses.

- Q: What are the common surface treatments for aluminum coils in the construction industry?

- The common surface treatments for aluminum coils in the construction industry include anodizing, painting, and powder coating. Anodizing creates a protective oxide layer on the surface, enhancing corrosion resistance. Painting provides aesthetic appeal and additional protection against environmental elements. Powder coating offers a durable and decorative finish by applying a powder coating material electrostatically and then curing it in high heat.

- Q: What are the differences among various types of steel wires and their respective coiling techniques?

- <p>Yes, there are differences between different types of steel wires and their coiling methods. Steel wires can be categorized based on their composition, strength, and use, such as carbon steel, stainless steel, and alloy steel wires. Each type has unique properties that affect their coiling methods. For instance, carbon steel wires are strong and ductile, suitable for standard coiling techniques, while stainless steel wires offer corrosion resistance and may require special handling to prevent damage. The coiling methods also vary; some common ones include spool coiling, loop coiling, and pancake coiling. Each method has specific applications and considerations for wire diameter, tension, and storage. Understanding these differences is crucial for selecting the appropriate wire and coiling technique for a given application.</p>

- Q: Can aluminum coils be used for heat exchangers?

- Yes, aluminum coils can be used for heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. These coils are typically used in applications where heat transfer is required, such as in HVAC systems, refrigeration units, and automotive radiators. The high thermal conductivity of aluminum allows for efficient heat transfer, while its corrosion resistance ensures durability and a longer lifespan for the heat exchanger. Additionally, aluminum coils can be easily formed into various shapes and sizes, making them versatile for different heat exchanger designs.

Send your message to us

Gpc143041 Hot Rolled Aluminum Coils for Oil Tanker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords