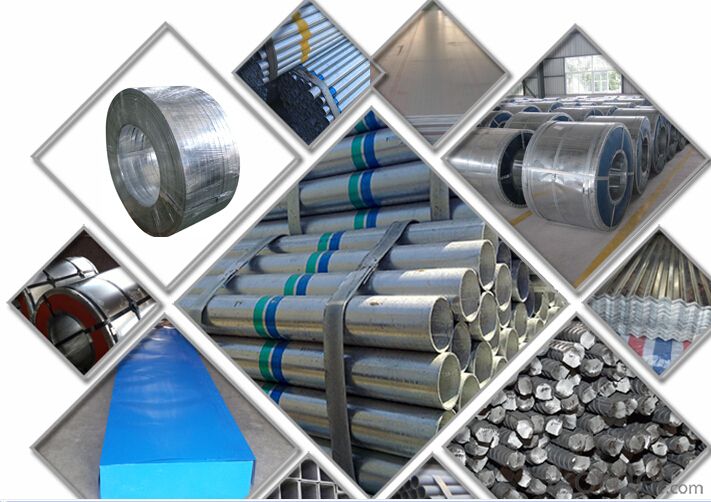

Good Quality New Colored Cold Rolled Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colored Cold Rolled Steel Coil description:

Standard:AISI,GB,JIS

Grade:DX51D+Z

Thickness:0.18-1.5mm

Model Number:prepainted steel coil

Type:Steel Coil

Technique:Hot Rolled

Surface Treatment:color coated/galvanized

Width:914-1250mm

Length:Coil

| Product Description of Colored Cold Rolled Steel Coil |

| Standard | ASTM,GB,JIS |

| Grade | DX51D+Z,SGCC |

| Thickness | 0.18-1.5MM |

| Width | 914,1000,1219,1250MM |

| Coil weight | 3-6mts |

| Top paint | 20MIL |

| Back paint | 7MIL |

| Surface treatment | color coated/galvanized/galvalume |

| Delivery time | 7-20 working days |

| Packing : | waterproof paper, galvanized steel covered and steel strip packed |

| USeage | widely used in construction,home,appliance,decoration,wear resistant steel,etc |

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: How do steel coils compare to other materials in terms of strength?

- Steel coils are renowned for their remarkable strength and durability, rendering them among the most robust materials obtainable in the market. In comparison to alternative materials like aluminum or plastic, steel coils demonstrate unparalleled strength and resilience against deformation or breakage. Due to the elevated tensile strength of steel, coils can withstand substantial loads, thereby rendering them perfect for diverse industrial uses, encompassing construction, automotive manufacturing, and the production of heavy machinery. Moreover, steel coils possess exceptional fatigue resistance, enabling them to endure repetitive stress and strain without compromising their structural integrity. This strength advantage positions steel coils as the preferred choice for applications that prioritize reliability and safety.

- Q: How do steel coils contribute to the construction industry?

- Steel coils are a crucial component in the construction industry as they are used to manufacture various structural elements like beams, columns, and girders. These coils are transformed into different shapes and sizes, providing the necessary strength and durability required for construction projects. Additionally, steel coils are also used in the production of roofing, siding, and other building materials, making them an essential resource in the construction industry.

- Q: Is condensation on steel caused from water being pulled out or is the condensation formed from the air around the steel object?

- When moist air comes in contact with the cooler steel, the water vapor changes to a liquid or condenses. Steel is made of iron and carbon, not water.

- Q: Is it possible to have a 25 room Hotel building with Steel structure. Thay is instead of traditional RCC can we have a 25 room hotel constructed using steel construction? Is it economic and how much time will it take to construct the same? Appraximate area would be 5000sq.ft to 10000sqft.

- it is possible...but with the current ever rising cost of steel...it is more expensive than reinforced concrete..... ...one more disadvantage is tat u have to use large I sections for the columns as steel do not take compression as good as concrete... ..tat is why u see..almost all totally steel structures are bridges where tensile strength rules more than compression.

- Q: What is the role of steel coils in the production of storage shelves?

- Steel coils play a crucial role in the production of storage shelves as they serve as the primary material for manufacturing the shelf frames and support structures. These coils are processed and formed into various components, such as beams and brackets, which provide strength and durability to the shelves. By using steel coils, storage shelves are able to withstand heavy loads and ensure long-lasting performance in commercial and industrial settings.

- Q: What bike companies make the best Steel Road bikes?

- Lots of good companies out there. Surly Pacer is one to check out.

- Q: What are the different steel coil finishes available?

- Some common steel coil finishes include hot rolled, cold rolled, galvanized, and coated finishes.

- Q: How are steel coils used in the production of metal cladding?

- Steel coils are used in the production of metal cladding as they are rolled into flat sheets and then formed into various shapes and profiles. These coils provide the raw material for manufacturing metal cladding panels, which are widely used in construction for their durability, weather resistance, and aesthetic appeal.

- Q: Apparently, this has to do something with electrochemical cells.

- Steel wool is a mild abrasive. I don't know what it is you are cleaning, but it is probably to remove any coating or oxidisation from the metal. Maybe you are using a metal for an electrode (perhaps a steel nail pushed into a lemon?).

- Q: Hi, I need to know why stainless steel is rust proof please tell me its for my science project. :)

- Stainless steel is characterized by the presence of chromium. Chromium oxidizes like aluminium does, by passivation, that is, it forms a though oxide layer that sticks to the metal underneath and protects it. On the other hand, iron oxidizes by turning into rust, which is a brittle material that flakes off, exposing the metal under for more oxidation. Now, what happens when you have a metal that is made of both iron and chromium? Any iron on the surface will rust and flake off (at the atomic level, so do not expect to see much rusting) until the surface is a pure chromium layer (again, we are talking about a layer that is a few atoms thick) and that chromium will oxidize but stay put. Then rust then has no way of getting deeper, and the metal will remain clean.

Send your message to us

Good Quality New Colored Cold Rolled Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords