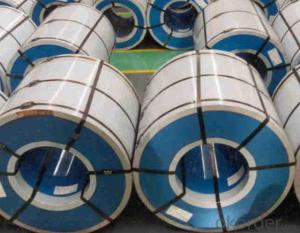

Good adhesion building material prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,JIS | Grade: | SGCC | Thickness: | 0.18-1.5 mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | CNBM | Model Number: | PPGI |

| Type: | Steel Coil,prepainted steel coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Construction,Electrial appliance,Furniture,Carrying trade,Others | Width: | 30-1250mm, mainly in 914, 1000, 1219, 1250mm | Steel grade: | CGC, CGCD, CGLCC, CGLCD |

| Packing weight(without pallet): | 25 kgs | Packing condition: | seaworthy | weight/coil: | 3-8 ton |

| Outside diameter: | according to the weight of coil | inside diameters: | 508 mm | Surface Finished color: | According to RAL standard |

Packaging & Delivery

| Packaging Detail: | SEAWORTH PACKING |

| Delivery Detail: | WITHIN 30 DAYS |

Specifications

Prepainted steel coil

1.Good adhesion.

2.The color not change.

3.Protective film can be covered.

4.Decoration.

Product Description

Prepainted steel coil Profile

A Prepainted Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality.

1.Steel grade: CGC, CGCD, CGLCC, CGLCD

2.Thickness:0.18-1.5 mm

3.Width: 30-1250mm, mainly in 914, 1000, 1219, 1250mm.

4.Surface Finished color : According to RAL standard

5.Coating Thickness: Min. Single Side coating Thickness: 50 g/sqm

Max. Single Side coating Thickness: 225 g/sqm

6.inside diameters: 508 mm

7.Outside diameter: according to the weight of coil

8.weight/coil :3-8 ton

9.Packing condition: seaworthy

Packing weight(without pallet):25 kgs

Packing weight(with pallet ):55 kgs

10.Delivery time :30 days (less than 500 ton )

Coat | Dope Type | Coat | Rigidity | Shine 60°(%) | Bend | Return | ||||

High | Middle | Low | Thickness≤0.75mm | Thickness>0.75 | ||||||

A | B | |||||||||

Second | PE | ≥20 | ≥F | >70 | 40-70 | <40 | ≤3T | ≤5T | 90° | ≥9 |

SMP | ≥20 | ≥F | >70 | 40-70 | <40 | ≤3T | ≤5T | 90° | ≥9 | |

PVDF | ≥20 | ≥F | -- | 40-70 | <40 | ≤2T | ≤5T | 90° | ≥9 | |

Plastisol | ≥100 | -- | -- | 40-70 | <40 | ≤1T | ≤5T | 90° | ≥9 | |

First | PE | ≥10 | ≥HB | >70 | 40-70 | <40 | ≤3T | ≤5T | 90° | ≥9 |

Prepainted steel coil Applications

Construction | Outside | workshop, agricultural, warehouse, residential precast unit, corrugated roof, wall, rainwater,drainage pipe, retailler booth, roller shutter door |

Inside | door,doorcase,ligh steel roof structure,folding screen,ceiling,elevator,stainway,vent gutter | |

Electrial appliance | refrigerator,washer,switch cabinet, instrument cabinate,air conditioning,micro-wave oven,bread maker | |

Furniture | central heating slice, lampshade,chiffarobe, desk, bed,lacker,bookshelf | |

Carrying trade | exterior decoration of auto and train, clapboard,container,lsolation board | |

Others | writing panel, garbage can,billboard,timekeeper, typewriter,instrument panel,weight sensor,photographic equipment | |

Wood grain and marble are also available

The Remarks for the marble color coated steel.

1. Good adhesion , can be roll forming easily for the marble color coated steel.

2. The color not change even after being roasted under high temperture for 6-12 years.

3. Process: Continuous coil coating line --- 3 coating and 3 bake.

4. Protective film can be covered.

5. The marble color coated steel can be easily used for the decoration. the building material, the door, electronics. tiles.wallings.furnitures.militaries' building etc.

6. More marble colors can be choosed or can be disigned.

- Q: What is the role of steel coils in the manufacturing of pipes and tubes?

- Steel coils play a crucial role in the manufacturing of pipes and tubes as they serve as the primary raw material. These coils are unwound and then formed into the desired shape through various processes such as rolling, bending, and welding. The strength and durability of steel make it an ideal material for pipes and tubes, ensuring their ability to withstand high pressure, corrosion, and other demanding conditions.

- Q: what pokemon are week to steel type pokemon like lucario? help please, and thank you.

- I believe Ground-type, Ice-type, Rock-type, Dark-type, Normal-type, Psychic-type, and Ghost-type Pokemon are weak to a Lucario. Steel is super effective against Rock and Ice-type Pokemon. Fighting is super effective against Rock, Ice, Normal, and Dark-type Pokemon. The reason why I added Psychic-type and Ghost-type Pokemon to the list of Pokemon that are weak to a Lucario is because Lucaro has the ability to learn Dark Pulse at high levels, so if he knows this move, then he should be able to deal super effective blows to Ghost and Psychic-type Pokemon. Of course, these are only if the Pokemon that you are facing is a single-type Pokemon. The Pokemon that you face will determine if a move is weak against it or not. Study up on the Pokemon you are facing and what types they are so that you can determine if your Lucario will be super effective against it or not. Have your Lucario stay away from Fighting-type and Fire-type Pokemon as they are both super effective against Steel-type Pokemon. Hope this helps :)

- Q: How do steel coils contribute to the manufacturing of construction materials?

- Steel coils contribute to the manufacturing of construction materials by providing a reliable and versatile raw material. These coils are typically made from high-quality steel and can be easily shaped, cut, and formed into various components such as beams, pipes, and sheets. The strength and durability of steel make it ideal for use in construction, ensuring the integrity and longevity of buildings and structures. Additionally, the consistent quality and availability of steel coils enable efficient and cost-effective production processes, making them an essential element in the manufacturing of construction materials.

- Q: How are steel coils used in the production of pipelines?

- Steel coils are used in the production of pipelines as they are rolled into flat sheets and then formed into the required shape. These coils provide the necessary strength and durability for the pipelines, ensuring they can withstand the high pressure and harsh conditions they will be exposed to.

- Q: How are steel coils used in the production of automobile frames?

- Automobile frames rely heavily on steel coils, which are indispensable for their production. These coils, crafted from top-notch steel, undergo a process of uncoiling before being fed into a stamping press, where they assume various forms, constituting parts of the frame. The presence of steel coils is crucial as they furnish the frame with the requisite strength and rigidity, ensuring it can bear the vehicle's weight and maintain structural integrity. Once shaped, the coils are frequently welded together to construct the frame structure. This welding procedure securely binds the individual components, guaranteeing that the frame can endure the forces and strains encountered during the vehicle's operation. Utilizing steel coils in the production of automobile frames also allows for design flexibility, as they can be effortlessly shaped and manipulated to fulfill specific requirements. Moreover, steel coils possess exceptional durability and corrosion resistance, rendering them ideal for automotive applications. Frames fashioned from these coils are not only robust and dependable but also capable of withstanding harsh conditions and road vibrations. This not only enhances the vehicle's safety but also contributes to its longevity and overall performance. Steel coils also find use in other critical vehicle components, including suspension systems, chassis, and body panels. Their versatility, strength, and cost-effectiveness make them a favored choice in the automotive industry. Overall, the incorporation of steel coils in automobile frame production plays a significant role in guaranteeing the safety, durability, and performance of modern vehicles.

- Q: What are the common uses of pre-painted steel coils?

- Pre-painted steel coils are commonly used in various industries such as construction, automotive, and appliances. They are utilized for manufacturing roofing and wall panels, garage doors, ductwork, and other building components. In the automotive sector, pre-painted steel coils are employed to produce body panels, trims, and other exterior parts. Additionally, they find applications in the manufacturing of household appliances like refrigerators, washing machines, and ovens.

- Q: Can steel coils be customized?

- Yes, steel coils can be customized according to specific requirements such as size, thickness, width, and even surface finish. Customization allows manufacturers to meet the unique needs of various industries and applications.

- Q: What are the various surface finishes available for steel coils?

- Steel coils offer a range of surface finishes, each with its own properties and uses. Some commonly used finishes include: 1. Hot rolled: Steel is rolled at high temperatures, resulting in a rough surface. This finish is great for structural applications like construction materials and industrial machinery. 2. Cold rolled: Steel is rolled at room temperature, creating a smoother surface. It is commonly used in automotive and appliance manufacturing due to its superior finish and accuracy. 3. Galvanized: Steel is coated with zinc to protect against corrosion. Galvanized coils have a shiny appearance and are suitable for outdoor applications such as roofing and fences. 4. Electro-galvanized: Coated with a thinner layer of zinc through an electroplating process, these coils offer good corrosion resistance. They are commonly used in electrical appliances, automotive parts, and construction. 5. Pre-painted: Coated with paint or polymer film, pre-painted coils provide both corrosion protection and aesthetic appeal. They are extensively used in construction for roofing, cladding, and wall panels. 6. Stainless steel: Stainless steel coils have unique properties, including corrosion resistance, heat resistance, and chemical damage resistance. They are ideal for industries like food processing, medical equipment, and marine applications. These examples showcase the variety of surface finishes available for steel coils. The choice of finish depends on factors such as the intended use, desired appearance, and level of corrosion resistance required.

- Q: I am searching for an online article which discusses any aspect of the use of austenitic stainless steels. I was just wondering if anyone could help me find one. No sales articles. Thank you!

- *Austenitic, okorder

Send your message to us

Good adhesion building material prepainted steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords