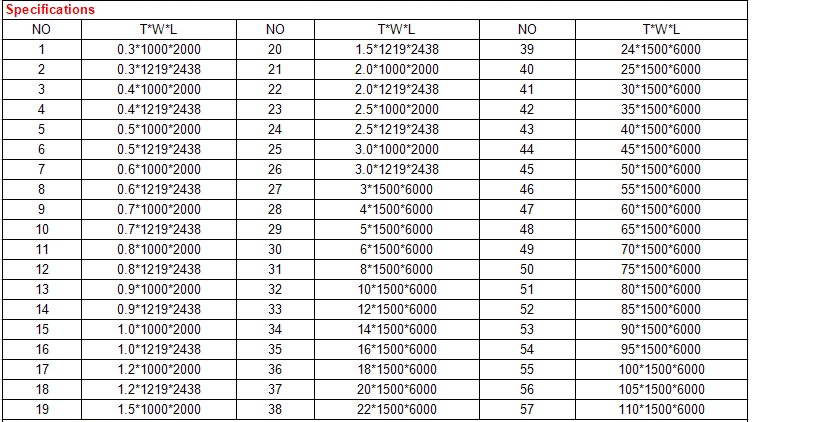

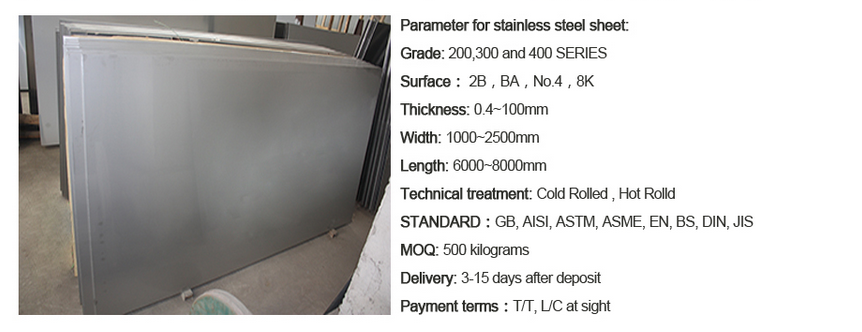

Gold supplier 201 304L 316 316L 304 stainless steel plate price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are stainless steel pipes suitable for chemical processing?

- Yes, stainless steel pipes are highly suitable for chemical processing due to their excellent corrosion resistance and ability to withstand high temperatures and pressures. They are also hygienic, durable, and have low maintenance requirements, making them a preferred choice for handling various chemicals in industries such as pharmaceuticals, petrochemicals, food processing, and more.

- Q: What is the maximum length of a stainless steel pipe?

- The maximum length of a stainless steel pipe can vary depending on various factors such as the manufacturing process, the specific grade of stainless steel used, and the intended application. In general, stainless steel pipes can be manufactured in lengths ranging from a few feet to several hundred feet. However, it is important to consider practical limitations such as transportation and installation requirements, as longer lengths may pose logistical challenges. Additionally, longer pipes may be prone to increased structural stress and potential for bending or sagging. Therefore, it is advisable to consult with a manufacturer or supplier to determine the maximum length of a stainless steel pipe suitable for a specific application.

- Q: Is galvanized steel pipe stainless steel pipe?

- Not galvanized pipe, but the surface of the welded pipe galvanized zinc rust protection. The stainless steel pipe is welded by stainless steel band, or made of stainless steel bar punched (seamless pipe). And the two prices are very different

- Q: Can stainless steel pipes be used for brewery and beverage industry applications?

- Yes, stainless steel pipes can be used for brewery and beverage industry applications. Stainless steel is highly resistant to corrosion, making it suitable for handling liquids and beverages. It is also easy to clean and maintain, ensuring the hygienic requirements of the industry are met. Stainless steel pipes are commonly used in these industries due to their durability, longevity, and compatibility with various fluids.

- Q: What is the difference between Type 409 and Type 410 stainless steel pipes?

- Type 409 and Type 410 stainless steel pipes are two different grades of stainless steel that have distinct characteristics and applications. Type 409 stainless steel is a ferritic stainless steel that contains a lower percentage of chromium compared to Type 410. It is primarily composed of iron, carbon, and up to 11% chromium. This composition gives Type 409 stainless steel good corrosion resistance in low-oxygen environments and moderate resistance to pitting and crevice corrosion. It is often used in applications where high-temperature oxidation resistance is not required, such as automotive exhaust systems, catalytic converter shells, and heat exchangers. On the other hand, Type 410 stainless steel is a martensitic stainless steel that contains a higher percentage of chromium (around 11-13%) and a small amount of nickel. This composition provides Type 410 stainless steel with excellent corrosion resistance and good mechanical properties. It is a general-purpose stainless steel that can be heat treated to achieve high strength and hardness. Type 410 stainless steel is commonly used in applications where corrosion resistance and/or wear resistance is required, such as cutlery, surgical instruments, valves, and pump parts. In summary, the main difference between Type 409 and Type 410 stainless steel pipes lies in their composition and resulting properties. Type 409 stainless steel is a ferritic stainless steel with good corrosion resistance in low-oxygen environments, while Type 410 stainless steel is a martensitic stainless steel with excellent corrosion resistance and higher strength and hardness. The choice between these two types of stainless steel pipes depends on the specific application requirements and the desired properties needed for that application.

- Q: How do you calculate the required support spacing for stainless steel pipes?

- To calculate the required support spacing for stainless steel pipes, several factors need to be taken into consideration. These factors include the pipe diameter, the material's weight, the temperature of the system, the fluid flowing through the pipe, and the desired safety factor. The first step is to determine the pipe diameter. This can be measured directly or calculated using the pipe's schedule and nominal size. Once the diameter is known, the weight of the stainless steel pipe per unit length can be determined using the density of stainless steel. Next, consider the temperature of the system in which the pipe will be operating. Stainless steel pipes can expand and contract with temperature changes, and this thermal expansion needs to be accounted for when determining support spacing. The thermal expansion coefficient of stainless steel can be used to calculate the expected expansion over the temperature range. The fluid flowing through the pipe should also be considered. If the fluid is corrosive or has high velocity or pressure, additional supports may be required to prevent excessive vibration or stress on the pipe. Lastly, the desired safety factor should be taken into account. This factor represents the additional support spacing required to ensure the integrity and stability of the pipe system. Common safety factors range from 1.5 to 3, depending on the specific application and industry standards. Once all these factors are known, various industry standards and guidelines can be used to calculate the required support spacing for stainless steel pipes. These standards provide formulas and tables that take into account the aforementioned factors, allowing engineers and designers to determine the appropriate distance between pipe supports. It is important to note that these calculations should be performed by qualified professionals with knowledge of industry standards and local regulations to ensure the safe and efficient operation of the stainless steel pipe system.

- Q: Are stainless steel pipes suitable for brewing systems?

- Yes, stainless steel pipes are highly suitable for brewing systems. Stainless steel is corrosion-resistant, non-reactive, and easy to clean, making it an ideal material for handling various brewing processes, including transporting water, wort, and beer. It helps maintain the purity and quality of the brew, ensuring there are no off-flavors or contaminants introduced during the process. Additionally, stainless steel pipes are durable and can withstand high temperatures and pressure, making them a reliable choice for brewing systems.

- Q: Why is the outer diameter of 1 inch galvanized pipe 33.7? And the outer diameter of one inch stainless steel pipe is 25.4

- The 1 inch galvanized pipe refers to the nominal size holes of 1 inches of water, the outer diameter is 33.7, its diameter fits a 1 inch pipe thread wire, and one inch stainless steel tube outer diameter is 25.4 that of the tube is in diameter standard specifications.

- Q: Can stainless steel pipes be cold worked?

- Yes, stainless steel pipes can be cold worked. Cold working is a process in which the metal is deformed at room temperature, typically through processes like bending, drawing, or rolling. Stainless steel's excellent mechanical properties and ductility make it well-suited for cold working, allowing for the creation of complex shapes and designs while retaining its strength and corrosion resistance.

- Q: What is the difference between nominal size and actual size in stainless steel pipes?

- The distinction between nominal size and actual size in stainless steel pipes lies in their measurement and labeling methods. Nominal size refers to the assigned name of a pipe based on its approximate dimensions, typically in inches or millimeters. This name serves the purpose of easy identification and standardization. In contrast, actual size refers to the precise measurements of the pipe, including its outer diameter (OD) and wall thickness. These measurements are usually expressed in fractions of an inch or millimeters. The accurate dimensions are vital for determining the pipe's compatibility with fittings, valves, and other components, as well as for calculating flow rates and pressure ratings. It is important to acknowledge that the nominal size of a stainless steel pipe may not always align with its actual size. This discrepancy arises from historical factors and manufacturing practices. In certain instances, the nominal size may be slightly larger or smaller than the actual size to account for variations in wall thickness or to conform to industry standards. Therefore, when selecting stainless steel pipes, it is crucial to consider both the nominal size and the actual size to ensure proper fit and functionality. Referring to the manufacturer's specifications or seeking professional advice can aid in determining the appropriate pipe size for a specific application.

Send your message to us

Gold supplier 201 304L 316 316L 304 stainless steel plate price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords