FACTORY DIRECT SALE -201 304 316L STAINLESS STEEL TUBE+COMPETITIVE PRICE with GOOD QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

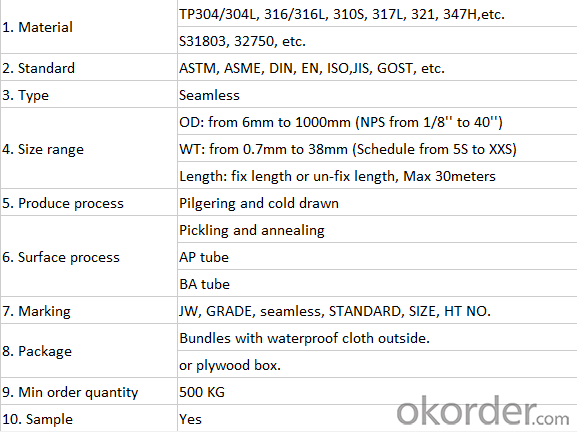

1,description of our factory direct sale of stainless steel pipe

2,Speciality and advantages:

Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

We have complete after-sale service to deal with the problems in time.

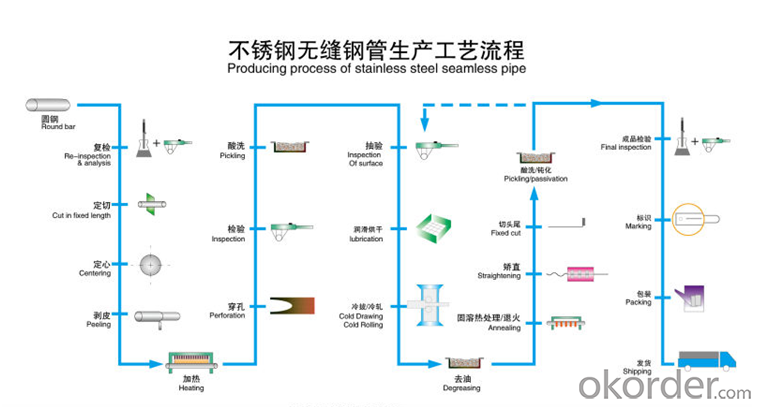

3,producing processing

4,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

3. Q: What is the application of 400 series stainless steel?

A: 410S stainless steel and 430 stainless steel are widely used for: kitchenware, tableware, cutleries, stainless steel pots, plates & bowls, sinks, gas stove, disinfection cabinet, household appliances, construction decorations etc. 409L stainless steel is usually used for exhaust pipe.

- Q: How are steel pipes used in the manufacturing of scaffolding?

- Steel pipes are commonly used in the manufacturing of scaffolding as they provide structural support and stability. These pipes are used to create the framework of the scaffolding structure, allowing workers to safely access and work at heights. The steel pipes are connected and secured together using couplers, providing a strong and reliable base for the scaffolding system.

- Q: How are steel pipes used in data centers?

- Steel pipes are commonly used in data centers for various purposes such as routing cables, running water cooling systems, and providing structural support for equipment. They are used to create a robust and organized network infrastructure, ensuring efficient and reliable data transmission and management within the facility.

- Q: Can steel pipes be used for conveying hazardous chemicals?

- Steel pipes can be used for conveying hazardous chemicals, as they are highly resistant to corrosion and can withstand high pressures. However, it is crucial to consider the compatibility of the chemicals with steel and ensure that appropriate safety measures and protective coatings are in place to prevent any potential leaks or reactions.

- Q: What is the difference between steel pipe and copper pipe?

- The composition and properties of steel pipe and copper pipe are what set them apart. Steel pipe is made from carbon steel, an alloy of iron and carbon, while copper pipe is made from naturally occurring copper. Durability is a key distinction. Steel pipe is renowned for its strength and resilience, making it suitable for high-pressure situations and harsh environments. It is highly resistant to corrosion, ensuring its longevity. On the other hand, copper pipe is prized for its malleability and ease of installation. It is not as durable as steel and can corrode over time, particularly when exposed to certain chemicals or aggressive water conditions. Another difference lies in thermal conductivity. Copper pipe is an exceptional heat conductor, making it perfect for applications requiring efficient heat transfer, such as plumbing systems for hot water supply. Conversely, steel pipe has lower thermal conductivity compared to copper, which may affect its performance in specific applications. Cost is also an important factor. Copper pipe tends to be pricier due to the higher cost of copper as a raw material. Moreover, installing copper pipe necessitates specialized tools and techniques, which can increase overall expenses. Conversely, steel pipe is often more cost-effective and easier to work with, making it a popular choice for various applications. In conclusion, the primary discrepancies between steel pipe and copper pipe encompass their composition, durability, thermal conductivity, and cost. Each type possesses its own advantages and disadvantages, and the selection between them hinges on the specific requirements of the given application.

- Q: How do steel pipes handle ground freezing and thawing?

- Steel pipes are highly resistant to ground freezing and thawing due to their inherent strength and durability. They are designed to withstand extreme temperature variations without significant damage or deformation. Additionally, steel pipes have low thermal conductivity, meaning they do not transfer heat as easily as other materials, allowing them to maintain their structural integrity even in freezing conditions. Thus, steel pipes are an excellent choice for underground infrastructure and can effectively handle ground freezing and thawing.

- Q: Are steel pipes suitable for transporting fluids?

- Yes, steel pipes are suitable for transporting fluids. They have high tensile strength, durability, and resistance to corrosion, making them an ideal choice for transporting various fluids, including water, oil, gas, and chemicals, over long distances. Steel pipes are commonly used in industries such as oil and gas, water treatment, and manufacturing due to their ability to withstand high pressure and temperature conditions.

- Q: What are the different types of steel pipe fittings for chemical processing plants?

- There are various types of steel pipe fittings used in chemical processing plants, including but not limited to, elbows, tees, reducers, flanges, and couplings. These fittings are designed to connect and control the flow of fluids within the piping system, ensuring safe and efficient operation in industrial settings.

- Q: What are the different types of steel pipe supports for overhead piping?

- Some of the different types of steel pipe supports for overhead piping include clevis hangers, beam clamps, pipe straps, and pipe rollers. Clevis hangers are used to suspend the pipe from a beam or other structural element. Beam clamps attach the pipe to a beam or other support structure. Pipe straps are used to secure the pipe to a wall or other surface. Pipe rollers allow the pipe to move freely while providing support.

- Q: How are steel pipes used in the construction of water treatment plants?

- Due to their numerous advantages and suitability for this specific application, steel pipes find wide usage in the construction of water treatment plants. They serve various purposes to ensure the effective and dependable operation of these facilities. To begin with, steel pipes are commonly employed for transporting water from its source to the treatment plant. With their high durability and ability to withstand high pressure, they ensure the secure and safe delivery of water over long distances. Moreover, their resistance to corrosion is crucial in preventing any contamination of the water supply. Within the treatment plant, steel pipes are utilized in the distribution system to convey water to different treatment processes. Typically laid underground or integrated into the facility's infrastructure, they facilitate a seamless flow of water between different treatment units. Due to their exceptional strength and structural integrity, steel pipes are highly suitable for this purpose. Furthermore, steel pipes are utilized in the construction of various water treatment equipment. For example, they are incorporated into the construction of sedimentation tanks, where water is allowed to settle while impurities are removed. Similarly, steel pipes are used in the construction of filtration systems, where water passes through different layers of filters to eliminate contaminants. Another significant application of steel pipes in water treatment plants is their use in the construction of pumping stations. These stations are responsible for maintaining a steady water flow throughout the treatment process. To ensure efficient water movement between different treatment stages, steel pipes are employed in the design and construction of the pumping systems. To summarize, steel pipes play a critical role in the construction of water treatment plants. They are utilized for water transportation, distribution within the facility, construction of treatment equipment, and in the design of pumping stations. Their durability, resistance to corrosion, and exceptional strength make them an ideal choice for this essential infrastructure.

- Q: Galvanized steel pipe in addition to good rust resistance, what are the advantages?

- First, the surface of the steel pipe is treated by embroidery, which is more durable, not faster than the rapid oxidation, and will not form white rust on the steel tube;Two. The steel pipe is fully protected. After heating, each part of the steel pipe is plated with zinc, and the concave convex part is protected;

Send your message to us

FACTORY DIRECT SALE -201 304 316L STAINLESS STEEL TUBE+COMPETITIVE PRICE with GOOD QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords