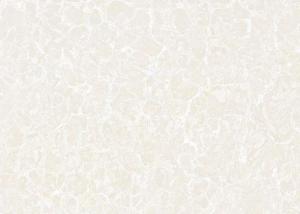

Glazed Porcelain Floor Tile 600x600mm CMAX-LP6036

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

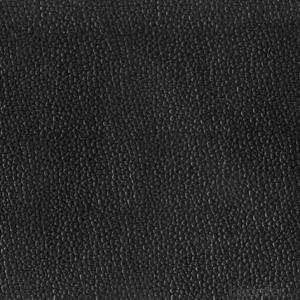

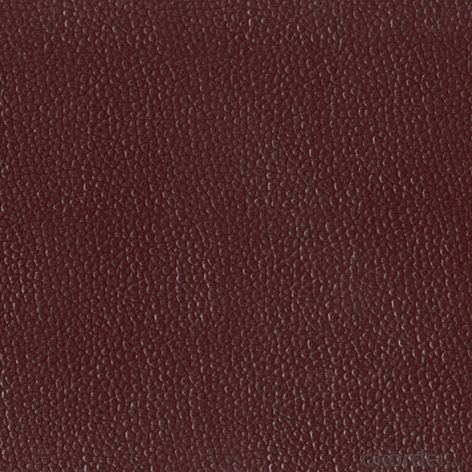

The glazed porcelain floor tile is wildly popular in Europe, North America and Middle East. The modle NO. CMAX-LP6036 is one of the popular designs in the present market. Just like other glazed porcelain floor tile, it could be used for interior floor and wall for apartment, villa, as well as other public areas, due to its unique antique feel image and texture. Besides, it is also proper for retails and distribution marketing channels.

Product Features

Excelent glaze surface and porcelain tile body

Grade AAA quality standard only

The basic size is 600*600mm, which could be cut into 30*60mm, 30*30mm, 15*60mm based on the actual project needs.

Strict quality control system on water absorption rate, color shade, deformation, anti-pollution, slip-resistance, abrasion resistance .

Compititive prices

Standard export packing: Pater Carton+ Solid Wooden Pallet

Fast production arrangement

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Product Specification

Tile Type: Glazed Porcelain Floor Tile

Quality standard: GB/T4100-2006, ISO13006,EN14411.

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1300 N

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.5%

Wearing Strength: 《1600 mm3

Slip Resistance: 》 0.5

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6m2/20’Fcl

For 300x600mm, 8pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6 m2/20’Fcl

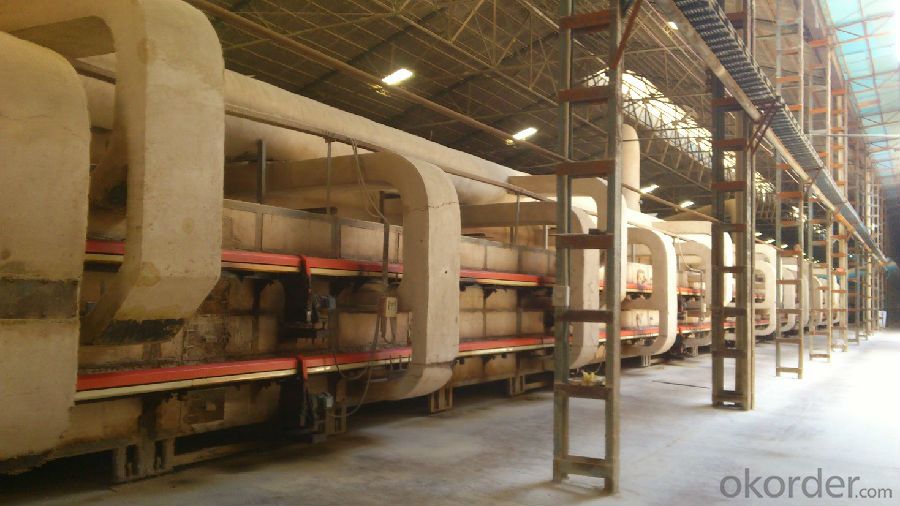

Production Line & Package

FAQ

1. What is the delivery time after we paid the deposit?

—— Normally, we shall get all items ready for loading within 3 weeks after we get the deposit or the formal Letter of Credit. For orders which demand cutting job, it will take a longer time.

2. For the delivery term, could you go with CFR our port?

—— Yes, of course. We have very good relationship with those big shipping company, such as COSCO, MSC, HPL etc. We have a very professional logistic team to arrange the shipping issue well.

3. Could we be your exclusive agent in our country?

—— Possibly. For some countries we are hoping to find a proper partner in working market together. For sure we need to have a good talking for the details.

4. Could we arrange the our own QC to check the items before container loading?

—— Yes, of course. Your quality checking will be welcome all the times.

5. What is the MOQ for this tile?

—— Normally the MOQ is one 20’ container. For those models whose production could be arranged frequently, we could mix 2 or 3 models in one container.

- Q: What are the high-end brands in the tiles?

- Golden rudder ceramic is to take the noble and luxurious line, to grade people to build, perfect match luxury Washington.

- Q: Our kitchen has vinyl tile squares from the 70‘s for the floor. Underneath that is terrazzo (sp?) and nothing else. They are proving to be a massive pain in the butt to remove so I was wondering if we even really need to. They are very thin and very stuck. Can we just skip tearing them out and go ahead with the new ceramic tile install?

- No, you are asking for trouble to consider leaving the vinyl tiles. I might suggest that you get a heat gun or use a regular iron with a dampened towel to help remove the vinyl tiles first.

- Q: It has been installed on a concrete slab for about five months now, could the slab not have cured right or is the tile layed wrong?

- here's the deal about laying tile over a concrete slab. either the tiler has to essentially build a floor over the slab (slab, then firring strips, plywood subfloor, thinset, backerboard, thinset, tile), or must use what's called an 'isolation membrane' to install the tiles directly on the slab (slab, then membrane, thinset, tile). the isolation membrane is a self-levelling rubbery substance that thinset can adhere to, that allows the slab to crack underneath without the cracks propagating upwards through the thinset and cracking the tile. if the tiler did neither, it's almost a guarantee that eventually the tiles over the slab will crack. (yes, if the slab had not fully cured, that might have caused the crack underneath; however, most all slabs will eventually crack even if everything else is perfect. that's the reason for the isolation membrane.)

- Q: My grandpa‘s bathroom needs to have a few adjustments made to it, namely safety bars put in place around the tub to help him in and out. The problem: every wall is covered in glazed tile (which I know makes a difference) and the bars need to be screwed in.My question is this: how? I know that using just a drill bit will shatter the tile, even a carbide one because the tile‘s glazed.Thanks much, kisses and ten points to the best answer.

- you got to get the screws in wall studs or they will just fail as soon as any weight is put on the bars. drilling thru a ceramic wall tile --- that part is easy.

- Q: According to the Home Depot book I should NOT install on top of existing vinyl tiles but according to the Lowes website I can if it is smooth and in good condition(which it is). It would be easier to install on top but I would like to do it the way that is the best.

- Yes, Vinyl can be installed over the top of vinyl. If it is sheet vinyl inspect for loose areas and cut a seam and reglue it down. If it is square (or similiar) tiles inspect each piece and if loose re-glue. There is no problem with laying over top of the old floor. I have renovated numerous homes and for mediocre money you can make a old floor look nice.

- Q: Not sure it it‘s mold/mildew ot the sealer stripping off. I‘ve used Tilex but it didn‘t work. Even scrubbed it with a stiff brush. Anyone know what this film is and how to get it off?

- Are these tiles applied directly to a concrete floor that sits on the ground? If so, it sounds like efflorescence, where salt moves from the ground into the floor and then through the tile appearing as a white film on the surface of the tile (it happens through basement walls and if bricks are placed on the ground). Scrubbing may not be enough. You may have to check at your local hardware store for a sealer for your tiles or a cleaner strong enough to prevent the film from forming again.

- Q: We purchased a 12 year old house and some of the ceramic floor tiles are cracked and need to be replaced. Where can you find old ceramic tile patterns? Do I have to replace the entire area?

- If you can get one tile to carry as your sample, then check stores that sell tiles. Doubt you will find them. Best bet is take sample to store that specializes in tile; they MAY have outdated tiles in their warehouse. Dig out some from area that could use contrast colors. Use pulled up ones (extra work to 'clean' back of old tiles) and replace the cracked/broken tiles. Use contrasting tiles around visible outside wall border or center of area. Now have 2 different colors but not replacing entire floor.

- Q: We are using some leftover floor tile (6x6 size) and some new decorative tile (2x2 and 1x1) to tile our backsplash. Can we use the same mortar that we used on the floor? Also, we used a 1/4 inch notched trowel when doing the floor -- should we use a smaller notch for the backsplash (say, a 1/8 inch notched trowel)? Finally, the floor tile and the 1x1 tiles are porcelain. The 2x2 tile is tumbled travertine with quite a few pits on the surface. We don‘t know if we should fill those pits with grout or not. On one hand -- it will make the tiles easier to clean if they are filled (yes?). On the other, we like the look of the pits and don‘t know if we want the grout (which is a slightly darker color) filling the pits. Any suggestions?

- Yes you can use the same mortar I prefer to use the 1/4 inch trowel because I've seen to many tiles not well enough adheard with the 1/8 inch.On the travertine I'm in agreement with you to keep the pits.Simply blue tape over the tiles then grout.Hope this helps 8 yr experienced tile installer.

- Q: all ceraminc tiles, mounted in between to tiles maybe?

- Your idea will not hold well and may be dangerous if you slip in shower and hit the shelf. Built-ins are better and safer.

- Q: would it be to hard for me to do by myself and is there an adhesive that I put under the tile?

- The okorder for eco-friendly home decor products and tips!

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-LP6036

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches