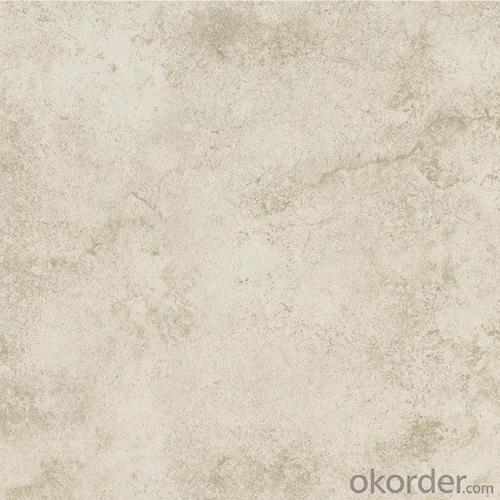

Glazed Porcelain Floor Tile 600x600mm CMAX-A6012

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

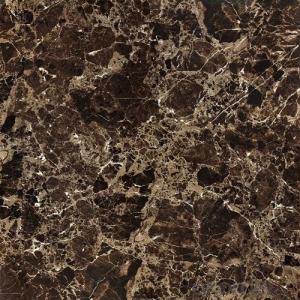

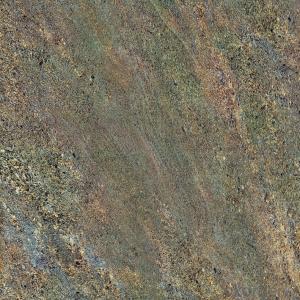

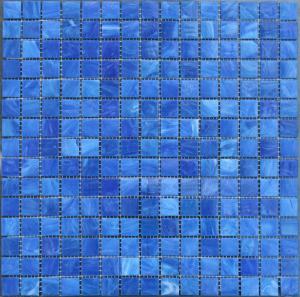

You Might Also Like

Product Brief Introduction

Glazed Porcelain Tile CMAX-A6012 is one of the popular colors in the present market. Just like other series, it could be used for interior floor and wall for apartment, villa, as well as other public areas, due to its unique antique feel image and texture. The glazed porcelain floor tile is wildly used in Europe, North America and Middle East.

Product Features

Glazed Porcelain Floor Tile

Grade AAA available only

Mainly the basic size is 600*600mm, which could be cut into 30*60mm, 30*30mm, 15*60mm.

Strict quality control system for monitoring water absorption rate, color shade, deformation, anti-pollution, slip-resistance, abrasion resistance as well as packing.

More competitive prices in China supplying market

Standard export packing: Pater Carton+ Wooden Pallet

Fast production arrangement

OEM service could be offered based on the actual requirement

Marketing support on samples, catalogues as well as carton designing

Professional sales team for the whole purchasing process.

Product Specification

Tile Type: Glazed Porcelain Floor Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1300 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.5%

Edge Straightness: ±0.5%

Wearing Strength: 《1600 mm3

Slip Resistance: 》 0.5

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6m2/20’Fcl

For 300x600mm, 8pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6 m2/20’Fcl

Production Line & Package

FAQ

1. For Glazed Porcelain Floor Tile, what is the difference from polished porcelain tile?

—— For Glazed Porcelain Floor Tile, there is a special glaze layer on the tile surface, which makes the surface feel matt or rough, while the surface of polished porcelain tile is glossy and smooth.

2. For the delivery term, could you go with CFR our port?

—— Yes, of course. We have very good relationship with those big shipping company, such as COSCO, MSC, HPL etc. We have a very professional logistic team to arrange the shipping issue well.

3. Could you company supply polished porcelain tile?

—— Yes. We could supply various kinds of polished porcelain tile, with size 60*60, 80*80, 100*100 and 60*120.

- Q: my husband put in tile in the motel i work at and it is ceramic tile and some of the rooms are popping up up can you tell me why? by the way could it be the climate i live in florida!

- Could be the humidity. What did he use to stick them down? Did he use a mastic that comes already mixed in a tub? If so, there will probably always be problems in a humid or wet areas. Thinset is best for tile.

- Q: Complete DIY newbie here with an outdated bathroom that I want to make a master. The floor is covered in hideous 1x1 tiles. I will replace this tile with some 12x12 or 8x8. Any suggestions on how to get this stuff off?

- If you are going to replace everything down to subfloor and start fresh, hammer the tiles to break them loose. Some people will use a sledge hammer also. Then you just have to use a flat edge shovel to pick up broken tiles and toss out. Have a wheel barrow or a garbage can lined with a contractors trash bag close by. (they are stronger than regular type) Wear a dust mask also, gets dust everywhere.

- Q: We are looking to buy a house and we‘re choosing between tile and hardwood floor. I prefer hardwood because I feel its easier to clean and more comfortable. Husband prefers the tile. Is it just personal preference or is one better than another, cleaning wise.

- cleaning hardwood floors or tile will more than likely be the same, cleaning wise. My personal preference is hardwood. They do have to be cleaned alot and you can feel any speck of dirt on them. I have tile floors in my kitchen and it is the same way. Sorry I don't believe this helps. compromise get both, my house has hardwood floors throughout and then in the kitchen and bathroom we have tile.

- Q: Just how long the renovation of the new house, my home bathroom tiles on the ground as long as the bath will be seepage, the investigation of the pipeline without problems, leaks are no problems, where the problem? Urgent to be resolved.

- You say is the bath water up to it! This is because the water can not flow in time when the water or water from the wall tiles and seepage, the ground tile pavement is empty shop, so the water will go back! If it is water infiltration, it goes without saying that waterproof is not done!

- Q: What purpose does it serve? Is it safe to assume the tile will settle half of the trowel thickness? For example, if using a 1/4 inch trowel, will the tile settle 1/8 inch when set in place? Thanks for any help/advice!

- Thinset cements the tile to the subfloor. The settling depends on the tile, and whether or not you press it down.

- Q: MyMy bathroom. which is about 75 square feet has a carpet and I want to change it to tile. The only utility is a toilet.How do I handle the toilet? If I use ceramic tile, does the toilet sit on the ceramic tile and does that cause a problem with breaking the tile?What do you recommend that is practical, easy to install, and still functional?

- You need to remove the toilet-it will give you a much better job as you will never make good cuts around it..The toilet wont crack your tiles..and a deep wax seal should work fine.After you pull that carpet I strongly suggest putting down wire mesh, or Hardi-Backer,,I dont care what some thin-set makers claim--I dont believe in putting tiles right on the wood.

- Q: I would appreciate a double check on this problem. I believe I‘ve saved myself a lot of cutting, but I just want to make sure. My shower is 59 inches wide. My tile is 4.25 inches wide and tall. (square)My spacers are .25 inches wide. The middle point of my shower 29.5 inches. If I move my center line to the right or left by 2 and 1/8 inches I should be able to cover the entire width with 13 tile IF I allow for a 1/8th inch addition in each corner. Is this correct?

- Ok so ignore your center line it does not matter here your tiles are 4.25, your grout lines are .25 and you are trying to get the tile and grout lines into a space that is 59 so if you take 13 tiles you get 55.25 for those tiles you will have 12 standard .25 grout lines totaling 3 giving you a total of 58.25 now from here what I would do instead of adding grout line and caulking on each end is form an L with the next wall (assuming you have 3 walls to tile to enclose the shower) because a standard wall tile is about .25 thick this would give you an 1/8 bead of caulk in each corner. Make sense?

- Q: There are 5 red tiles, 4 blue tiles 3 green tiles. whats the probablitiy of reaching into the bag and getting a blue tile and then, without replacing that tile, reaching into the bag again and getting a red tile?

- there are 12 tiles altogether probability of getting blue tile first is 4/12 but then there will be only 11 tiles so there is a probability of getting a red tile second is 4/11 so, 4/12 times by 4/11 which equals 4/33

- Q: can you tile an old brick fireplacegt;?would it look stupid?

- To do that it is a bit more complicated than it sounds. You would need to make the brick surface smooth, no crevaces. It's expensive time consuming. Consider resurfacing the fireplace

- Q: Dont worry about looks with the dollar tile just want to know pricing pretty much on the tile and how expensive it is.

- If you are doing the tile work yourself, it will be cheaper than having one of those fiberglass shower enclosures put in. You are looking at the cost of tile (at $1/sqft.), grout ($10 or less), permabase/durock ($9 per 3x5 sheet), mastic ($30 for high quality), and caulk ($4), to get the job done. On an average size shower, this will bring your total material bill in at right around $200. This is based on entirely ripping out your old shower walls (back to the studs), and building an entirely new shower. A complete rennovation for $200. This is what I do for a living, and I can honestly tell you that you will save tons if you are handy enough to do this yourself. One side note on the pre-fab showers (fiberglass, urethane, etc) - we get a lot of calls to come out and remove mold from these types of enclosures. On most that I've seen there are a lot of corners and small nooks that moisture gathers up and sits in. Just something to watch out for should you go that method. Good luck to you, either way.

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-A6012

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches