Glasswool and Rockwool Aluminum Foil FSK insulation facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

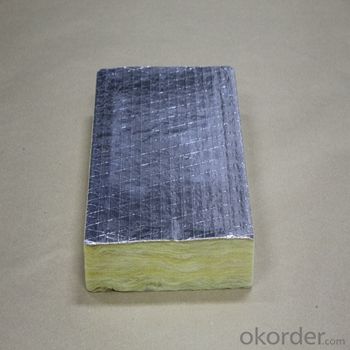

1. Aluminum Foil Facing Description:

Aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

2.Main Features of the Aluminum foil facing:

• Light weight

• Small inertia resistance

• High manufacturing accuracy

• Strong heat dissipation ability

• Good visual effect

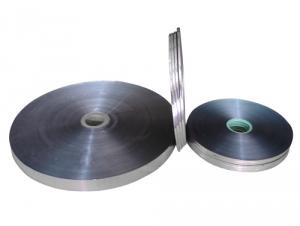

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

- Q: This question asks for various purposes that aluminum foil facing can be used for, other than its conventional use.

- <p>Aluminum foil facing has several alternative uses. It can be used as a reflective surface to enhance the heat distribution in grilling or baking. It can also serve as a protective barrier in gardening to deter pests or as a makeshift sled for sliding on snow. Additionally, it can be used to clean stubborn stains or as a shield to protect surfaces from paint splatters during home improvement projects. Some people even use it for crafting or DIY projects due to its malleability and reflective properties.</p>

- Q: Is it safe and practical to use aluminum foil facing as a protective layer for a cutting board?

- <p>Yes, you can use aluminum foil facing as a temporary cover for a cutting board. It provides a smooth surface that can protect the cutting board from scratches and stains. However, it's not recommended for long-term use or heavy-duty cutting as it may tear or dent easily. For regular use, a proper cutting board cover or a plastic cutting mat is more durable and safer.</p>

- Q: Is it safe and effective to use aluminum foil facing material for wrapping rice for storage purposes?

- <p>Using aluminum foil facing to wrap rice for storage is not recommended. Aluminum foil facing is not designed for food contact and may contain chemicals that could contaminate the rice. Instead, opt for food-grade materials like plastic bags or containers specifically designed for food storage. These materials are safer and help maintain the freshness and quality of the rice.</p>

- Q: This question asks for methods to clean aluminum foil after it has been used for cooking and has old food stuck to it.

- <p>To remove old food from aluminum foil facing after cooking, start by letting the foil cool down to avoid burns. Then, use a plastic scraper or the edge of a credit card to gently scrape off the food particles. For stubborn residue, you can soak the foil in warm, soapy water for a few minutes before scrubbing with a soft sponge or cloth. Avoid using metal scrubbers as they can scratch the foil. After cleaning, rinse thoroughly and dry before storing or reusing.</p>

- Q: Describe the process of aluminum foil facing in a few sentences.

- <p>Aluminum foil facing is a process used to laminate aluminum foil to a substrate, typically for decorative or functional purposes. The process begins with the preparation of the substrate, ensuring it is clean and free of contaminants. Then, a layer of adhesive is applied to the substrate. The aluminum foil is then placed onto the adhesive-covered substrate and pressure is applied to ensure proper adhesion. The laminated product is then cured, which can involve heat or UV light to set the adhesive. Finally, the product is trimmed and inspected for quality before being packaged and shipped. This process is used in various industries, including construction, automotive, and consumer goods.</p>

- Q: What are the eco-friendly options available to replace plastic containers?

- <p>Yes, there are several alternatives to plastic containers that are more environmentally friendly. Glass containers are a popular choice due to their durability and ability to be reused multiple times. Stainless steel containers are also a great option as they are long-lasting and do not leach chemicals. Biodegradable materials like bamboo, silicone, and certain types of plant-based plastics are other alternatives. Additionally, using cloth bags or reusable food wraps can help reduce the need for single-use plastic containers.</p>

- Q: Can aluminum foil be used as a substitute for a pizza stone or baking sheet when making pizza?

- <p>Yes, you can use aluminum foil as a makeshift surface for making pizza if you don't have a pizza stone or baking sheet. However, it may not provide the same even heat distribution or crispiness as a pizza stone. Ensure the foil is heavy-duty to prevent tearing and preheat it with the oven to get a better result. Keep in mind that the foil can reflect heat, which might affect the bottom crust's texture. It's a good alternative, but for consistent quality, using a proper pizza stone or baking sheet is recommended.</p>

- Q: What specific safety measures should be considered when utilizing aluminum foil in a kitchen setting?

- <p>When using aluminum foil in the kitchen, it's important to handle it carefully to avoid sharp edges that can cause cuts. Avoid using it in direct contact with an open flame as it can melt and release toxic fumes. Do not use aluminum foil with non-stick cookware as it can damage the surface. Keep it away from high heat sources like broilers and never use it to line baking sheets as it can catch fire. Always ensure that any food wrapped in aluminum foil is sealed properly to prevent the foil from coming into contact with heat sources directly.</p>

- Q: Is it possible to use aluminum foil with a reflective side facing up for cooking or frying food?

- <p>Using aluminum foil with a reflective side facing up for frying food is not recommended. Aluminum foil is not designed for direct contact with high heat sources like frying pans or oil. It can cause uneven heating, stick to the food, and potentially release harmful aluminum particles into the food. For safe and effective cooking, use appropriate cookware designed for high heat and direct contact with food.</p>

- Q: What are the particular criteria or considerations when choosing aluminum foil facing materials?

- <p>When selecting aluminum foil facing, specific requirements include the foil's thickness, which affects durability and insulation properties; surface finish, which can impact heat reflection and aesthetics; and the type of adhesive used for bonding, which should be resistant to heat and moisture. Additionally, the foil should have good barrier properties to prevent moisture and air infiltration, and it should be compatible with the substrate materials to ensure a strong bond. Compliance with safety and environmental standards is also crucial.</p>

Send your message to us

Glasswool and Rockwool Aluminum Foil FSK insulation facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords