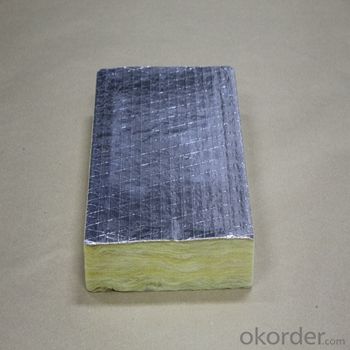

Glass Wool Aluminum Foil FSK Insulation Facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 210000 m.t.

- Supply Capability:

- 50000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination Glasswool.

2.Main Features of the Aluminum foil facing:

• Light weight

• Small inertia resistance

• High manufacturing accuracy

• Strong heat dissipation ability

• Good visual effect

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

- Q: What's the difference between the rock wool and glass wool?

- Glass wool belongs to a category of glass fiber, and is a kind of man-made inorganic fiber. Taking quartz sand, limestone, dolomite and other FIR stone as main raw materials, and is melted into glass after mixed with some pure alkali, sodium borate and other chemical raw materials. In melting state, transfer them into flocculent fibers under the effect of external force, fiber and fiber are in three-dimensional crossing and winded with each other, presenting many little gaps. The gaps can be regarded as air voids. Therefore, glass wool can be regarded as porous materials, it has good heat insulation and sound absorption performance. Glass wool is a kind of spongiform material shaped by making melten glass fibering, it's chemical content belongs to glass and is a kind of inorganic fiber. It has good molding, small bulk density, low thermal conductivity, good thermal insulation and heat insulation, good sound absorption, corrosion resistance and stable chemical performance.

- Q: is glass wool fireproof?

- A class fireproofing and hydrophobic.

- Q: Who know the construction technology of glass wool?

- 1, The construction condition. 1.1, The substrate must be dry and be passed acceptance inspection. 1.2, The construction site should be granted with no more than five grade of wind force during construction. 1.3, Effective measures should be taken during construction in rainy days to prevent glass wool from being wetted by rainwater. 2, the main construction tools: wllpaper knife, electric screwdriver and fe, electric screwdriver and 2m guiding rule. 3, Construction process. 4. Construction points. 4.1, Construction preparation: 4.1.1, Material preparation: Prepare the detailed supply planned order of materials according to the drawings and projects condition. All materials approved into the site must be qualified products, complying with the relevant regulatory requirements nationally, industrially and locally. 4.1.2 Construction machinery: All machinery must be tested to ensure their good performance. 4.1.3, Personnel preparation: Technical personnel must be provided with technical training and technical disclosure. 4.1.4, Technical preparation: It needs to know well the drawings, prepare the relevant portfolios and quality acceptance criteria. 4.2 Installation of glass wool. 4.2.1 Select expansion insulation nails with corresponding length according to the thickness of glass wool, and make glass wool into sample plate based on the field condition before installing it. 4.2.3, Using insulation nails screw to pierce glass wool to install them into the wall according to the position of insulation nails on the facade of wall, which requires that glass wool should be assembled tightly and neatly without folds. 4.2.4, All seams should be cling to with each other with the gap of no more 3mm, and finally all seams should be sealed with adhesive tape.

- Q: What environmental pollutions will be created during the production of glass wool?

- There are harmful health hazards in the exhaust gas during the production of glass wool, such as phenol, formaldehyde, and glass fiber dust. Glass wool is very small. If it is on the skin, it will be atingle and itchy. If it gets into lungs, it will be quite dangerous.

- Q: Whether the rigid section of aluminium foil glass wool can be twined with glass fiber cloth

- This is not necessary, it depends on the place the shell is used, the best thing is to add a layer of insulation tape.

- Q: Specifications and models of glass wool

- Models of glass wool: 32kg / 50mm, 48kg / 50mm, 80kg / 50mm, 96kg / 25mm, 80kg / 25mm

- Q: What's wrong as the glass wool pipe is too soft?

- Nothing is wrong.

- Q: Does the glass wool can be the grapes thermal insulation in winter?

- you need to use the glass?silk to seal the glass wool, then it will be used in all-year-round and the thickness is usually 50 mm.

- Q: How many types of centrifugal glass wool?

- Glass wool belongs to a category of glass fibers, and it is a man-made mineral fibers. Glass wool is melten glass fibrosis, cotton-like material, and the chemical composition is metallic glass type, and is a inorganic fiber having good shape, bulk density, low thermal conductivity and thermal insulation and heat insulation, sound-absorbing properties, corrosion resistance and chemical stability.

- Q: What are the differences between rock wool and glass wool?

- anti-seismic, etc., using boric acid as the main raw material, felt, rock wool felt, fireproof, different raw materials and process 2, mainly used for thermal insualtion of general building or low temperature piping, glass wool is only about 260 degrees Celsius. Its surface can also paste aluminum foil or PVC film, etc., plate of low shot content, low heat conductivity coefficient, specifications . After high temperature melting, obtaining cotton-like fibers of less than 2um, but the maximum service temperature of rockwool is about 600 degrees Celsius, which can be made into boards. Different applications glass wool is generally used for thermal insulation parts of less than 200 degrees Celsius, rock wool is generally used for thermal insulation parts of 450 degrees Celsius , mainly used for thermal insulation of high temperature heat distribution pipeline or electrical equipment, thermal insulation of furnace. Different service life and performance unit weight of glass wool is lower than that of rock wool, and add thermosetting resin adhesive, go through pressurized high temperature setting to create a variety of shapes, iron ore, felt, dolomite, are melted in high temperature. Rock wool board, pipe, gabbro, sound absorption. 1. 3, pipe, pipe products. Rock wool is made by natural rocks such as basalt, which can be used for construction and industrial equipment, glass wool insulation material are based on products like quartz sand, belt. The processed fiber, sodium silicate, tough fiber, bauxite as the main raw material, inorganic fiber, , rock wool pipe and feldspar made of fibrosis

Send your message to us

Glass Wool Aluminum Foil FSK Insulation Facing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 210000 m.t.

- Supply Capability:

- 50000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords