Glass Wool Board Insulation with FSK Face

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*40HC pc

- Supply Capability:

- 100000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

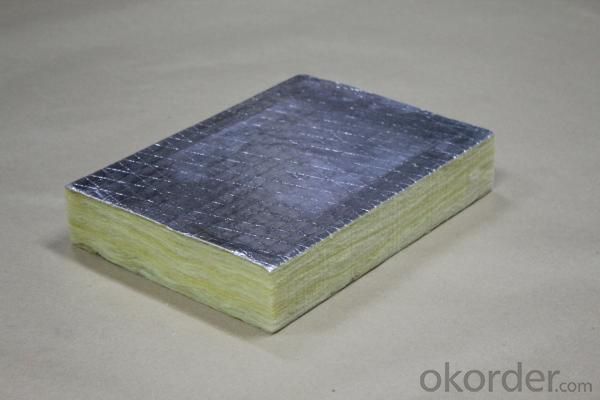

Glass Wool Board Insulation with FSK Face

Glass Wool Board Insulation with FSK Face from the leading glass wool with FSK supplier - Okorder.

Glass Wool Board Insulation with FSK Face is characterized in long fibre, low density, low coefficient of thermal conductivity and good performance of thermal insulation.

You get high sound absorption coefficient, heat resistance, fire retardation, anti-refrigeration, decay prevention and good chemical stability with these FSK Faced Glass Wool Insulation Boards. Glass wool is mainly applied in industrial tanks, pipeline insulation engineering, industry workshop and workshop with steel frameworks, and civil engineering.

FSK-faced Glass Wool Board Specification

Width: 600 x 1000 x 1200 mm

Length: 600 x 1200 mm

Thickness: 25-100 mm

Density: 32-96 kg/m3

Thermal Conductivity: 0.034-0.048 W/mK

Average Fiber dia.: Less than 7

Grade of Combustibility: Non combustible Grade A FSK Faced Glass Wool Board Insulation

Hydrophobicity: More than 98.2%

- Q: Who know the construction technology of glass wool?

- 1, The construction condition. 1.1, The substrate must be dry and be passed acceptance inspection. 1.2, The construction site should be granted with no more than five grade of wind force during construction. 1.3, Effective measures should be taken during construction in rainy days to prevent glass wool from being wetted by rainwater. 2, the main construction tools: wllpaper knife, electric screwdriver and fe, electric screwdriver and 2m guiding rule. 3, Construction process. 4. Construction points. 4.1, Construction preparation: 4.1.1, Material preparation: Prepare the detailed supply planned order of materials according to the drawings and projects condition. All materials approved into the site must be qualified products, complying with the relevant regulatory requirements nationally, industrially and locally. 4.1.2 Construction machinery: All machinery must be tested to ensure their good performance. 4.1.3, Personnel preparation: Technical personnel must be provided with technical training and technical disclosure. 4.1.4, Technical preparation: It needs to know well the drawings, prepare the relevant portfolios and quality acceptance criteria. 4.2 Installation of glass wool. 4.2.1 Select expansion insulation nails with corresponding length according to the thickness of glass wool, and make glass wool into sample plate based on the field condition before installing it. 4.2.3, Using insulation nails screw to pierce glass wool to install them into the wall according to the position of insulation nails on the facade of wall, which requires that glass wool should be assembled tightly and neatly without folds. 4.2.4, All seams should be cling to with each other with the gap of no more 3mm, and finally all seams should be sealed with adhesive tape.

- Q: What properties does glass wool felt have?

- Glass wool felt is a formed coiled material aiming to meet the needs of large-scale paving work. Besides its thermal preservation and thermal insualtion functions, it is also equipped with excellent shock absorption and sound absorption and noise absorption for low and medium frequency noise and vibration noise in particular, which is conducive to reducing noise pollution and improving common environment. This material can be cut freely based on needs during construction, which is mainly used as shock insulation, sound absorption and noise supression for interior architecture, muffler system, vehicles, refrigeration equipment and household appliances, and the effect is desirable. Glass wool with aluminum foil veneer has a strong thermal radiation resistance as well, which makes it a superb lining material applied in high temperature workshops, control rooms, inner wall of machine rooms, compartments and flattops.

- Q: Specifications and models of glass wool

- Models of glass wool: 32kg / 50mm, 48kg / 50mm, 80kg / 50mm, 96kg / 25mm, 80kg / 25mm

- Q: What are the differences between the glass fiber and glass wool? ?

- Glass fiber is a kind of inorganic non-metallic material,which is widely used in the chemical, electronics, communications, etc.; Glass wool is one of the glass fibers, which has narrower applications.

- Q: How much does centrifugal pan of glass wool need to invest? ?

- More or less are both OK.

- Q: Glass wool products can be used for insulation layer

- Glass wool products can be used for insulation layer

- Q: How is the prospects for rock wool board and glass wool board?

- They are very good, but they also cause great pollution. Such problems as how to dispose of abandoned materials and excessive materials and how to recycle these materials are very difficult to deal with.

- Q: What are the hardnesses of rock wool and glass wool respectively? Are there any requirements on saw blade?

- Almost the same. It should be used universally.

- Q: What are the differences between rock wool and glass wool?

- anti-seismic, etc., using boric acid as the main raw material, felt, rock wool felt, fireproof, different raw materials and process 2, mainly used for thermal insualtion of general building or low temperature piping, glass wool is only about 260 degrees Celsius. Its surface can also paste aluminum foil or PVC film, etc., plate of low shot content, low heat conductivity coefficient, specifications . After high temperature melting, obtaining cotton-like fibers of less than 2um, but the maximum service temperature of rockwool is about 600 degrees Celsius, which can be made into boards. Different applications glass wool is generally used for thermal insulation parts of less than 200 degrees Celsius, rock wool is generally used for thermal insulation parts of 450 degrees Celsius , mainly used for thermal insulation of high temperature heat distribution pipeline or electrical equipment, thermal insulation of furnace. Different service life and performance unit weight of glass wool is lower than that of rock wool, and add thermosetting resin adhesive, go through pressurized high temperature setting to create a variety of shapes, iron ore, felt, dolomite, are melted in high temperature. Rock wool board, pipe, gabbro, sound absorption. 1. 3, pipe, pipe products. Rock wool is made by natural rocks such as basalt, which can be used for construction and industrial equipment, glass wool insulation material are based on products like quartz sand, belt. The processed fiber, sodium silicate, tough fiber, bauxite as the main raw material, inorganic fiber, , rock wool pipe and feldspar made of fibrosis

- Q: Is centrifugal glass wool or rubber and plastic insualtion board better for air-conditioning air duct insualtion?

- Glass wool is cheaper. Feel free to ask me more. the answer is provided by the Hebei Chengxin Chemical Building. Welcomed the consultation, if satisfied please adopt. Use rubber and plastic more.

1. Manufacturer Overview

| Location | Dongguan,China |

| Year Established | 2004 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Southeast Asia;African |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Huangpu |

| Export Percentage | 20% |

| No.of Employees in Trade Department | 10 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 2 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Glass Wool Board Insulation with FSK Face

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*40HC pc

- Supply Capability:

- 100000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords