Glass Wool Good Quality Blanket

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Good Quality Glass Wool Blanket for thermal Insulation

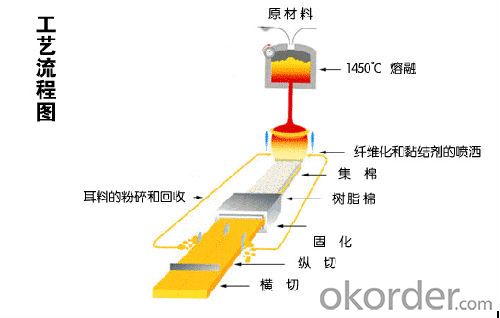

1.Structure of Glass wool Blanket for thermal Insulation:

Glass wool is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Blankets. This product is used as insulation and in other applications, like for air filters. It is available through home supply stores and manufacturers can also produce wools for special purposes, like insulation in aircraft, where the standards may be higher for health and safety reasons. Numerous companies make glass wool products along with lines of other insulation materials for a variety of applications.

Glass wool raw materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

The Manufacturing Process

Melting / Forming into fibers /Continuous-filament process/Staple-fiber process/ Chopped fiber/ Glass wool / Protective coatings /Forming into shapes

2.Main Features of Glass wool Blanket for thermal Insulation:

The glass wool Blanket is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Blankets, Blankets and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

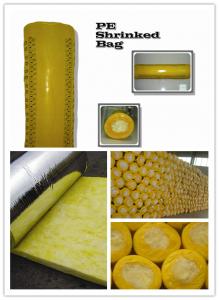

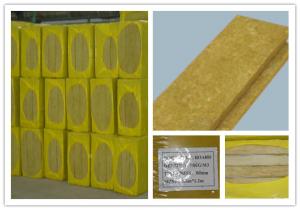

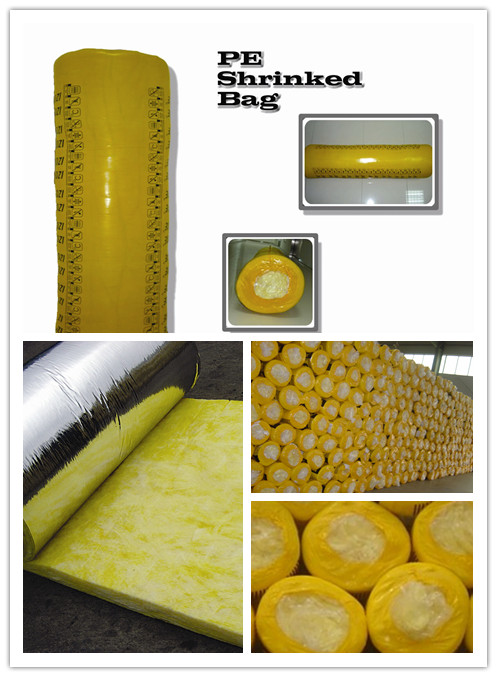

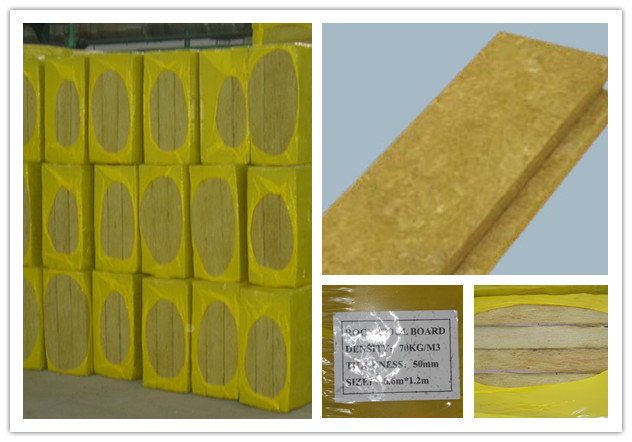

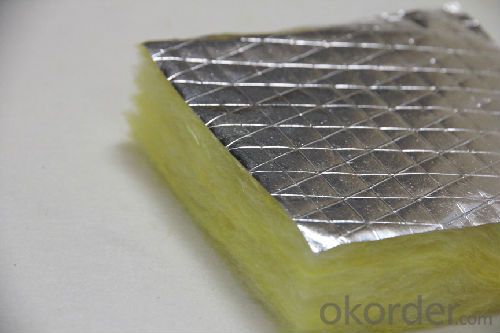

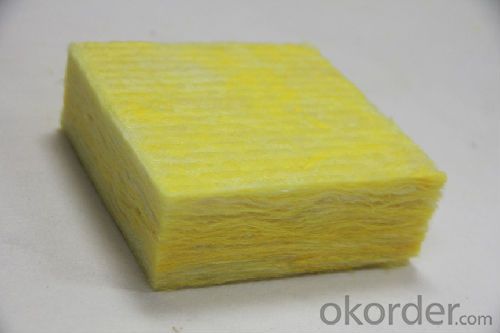

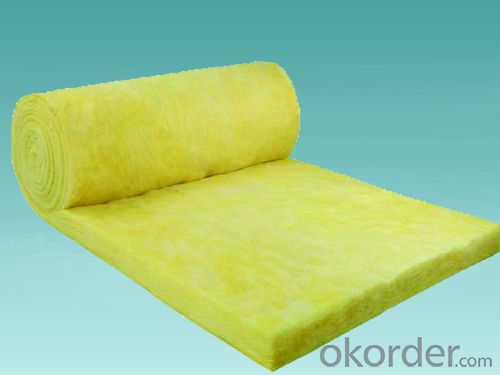

3. Glass wool Blanket for thermal Insulation Images

4. Glass wool Blanket for thermal Insulation Specification

The glass wool Blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool Blanket with aluminum foil surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 12-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 1200-3000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.

use a variety of standardized test procedures to measure, adjust, and optimize product acoustical resistance, sound absorption, and sound barrier performance. The acoustical properties can be controlled by adjusting such production variables as fiber diameter, bulk density, thickness, and binder content. A similar approach is used to control thermal properties.

- Q: What are the advantages and disadvantages of centrifugal glass wool?

- They both have the heat preservation and thermal insulation effects. Except for different materials and prices, their high temperature endurances are different with rock wool of 600 degrees, glass wool of 450 degrees and rubberplastic sponge of 120 degrees, but they are both fire?retardant materials. Rock wool and glass wool also have sound insulation and shock insulation effects, while these effects of rubberplastic sponge is worse. Rock wool and glass wool can not be used outside the door.

- Q: what's the differences between glass wool roll mat and rock wool roll mat? does glass wool roll mat have any mandatory retest requirements or environmental requirements?

- Steel structure roof basically uses glass wool roll mat, because rock wool roll mat is six to ten times heavier than glass wool roll mat, light steel frame can't bear so much gravity, glass wool is more fluffy than rock wool, so it's thermal insulation effect is better, glass wool is cheaper than rock wool, the glass wool fire rating is A-level flame retardant, now people won't use the rock wool blanket, wall thermal insulation used rock wool board.

- Q: How to conduct thermal insulation construction of external wall glass wool?

- Firstly fix glass wool with insulation nails to the wall so as to prevent glass wool from falling. It is so essential to make a vapor barrier on the surface of glass wool so as to avoid moisture condensation of water in the air in glass wool and reduce insulation properties.

- Q: what is the raw materials producing glass wool insulation materials?

- Asbestos

- Q: What is the difference between glass wool and rock wool?

- Production of raw materials and different processes

- Q: Glass wool and pef air conditioning insulation material, which one is better?

- So many air-conditioning installation company will choose this new PEF thermal insulation cotton and rubber and plastic thermal insulation material. Generally many companies prefer to use PEF thermal insulation cotton for duct, and rubber and plastic thermal insulation material for water pipes. Productions can be selected according to each person's favor, but we can't only select the cheap products when selecting, and we should choose guaranteed green products.

- Q: What is the highest temperature that the fireproof glass?cotton can resist?

- It is certain that A level is the highest. A level indicates that it is non-combustible. Level B indicates that it is fire?retardant. Rock wool can resist 800 ℃ and glass wool can resist 450 ℃. The hest perservation effect of matetials of B level is relatively better.

- Q: What is the density of glass wool?

- Name: Common glass wool. Fibre?diameter (um) & lt; 15 Apparent density (kg / (m ^ 3)) 80 ~ 100 heat conductivity coefficient at room temperature (W / (m * K)) 0.052 Heat resistance (℃) ≤300 sound absorption coefficient - Notes : 1. The temperature should not exceed 300 ℃. 2. The corrosion resistance is poor. Name: Common ultra-fine glass wool fibre diameter ... Name: Common glass wool fibre?diameter(um) & lt; 15 Apparent density (kg / (m ^ 3)) 80 ~ 100 heat conductivity coefficient at room temperature (W / (m * K)) 0.052 heat resistance (℃) ≤300 sound absorption coefficient - Notes: 1. The temperature should not exceed 300 ℃. 2. The corrosion resistance is poor. Name: Common ultra-fine glass wool fibre?diameter (um) & lt; 5 Apparent density (kg / (m ^ 3)) 20 normal temperature at room temperature (W / (m * K)) 0.035 Heat resistance (℃) ≤400 acoustical absorption coefficient ≥0.075 Note: In general, the temperature should not exceed 300 ℃ detail <i class="i-incline-down"></i>

- Q: What's the difference between glass?wool?board and rock wool board ?

- In fact, it is very simple. Glass wool is processed from glass (silicon?dioxide) , while rock wool is made from basalt or diabase through high temperature refining equipment, which are two completely different products. Hope it is helpful.

- Q: Why does glass wool turn black when exposed to heat? Wether it will ffect the thermal insulation effect.

- The burning like alcohol lamp uses glass wool as the substrate. There are two possibilities to take alcohol lamp to do experiment, which containing organic substances. 2. 1, High temperature oxidation. I produce aerogel thermal insulation felt, and I have seen that the charcoal ash produced is attached to the glass wool. It has some impact on thermal insulation effect, but the impact is small.

Send your message to us

Glass Wool Good Quality Blanket

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords