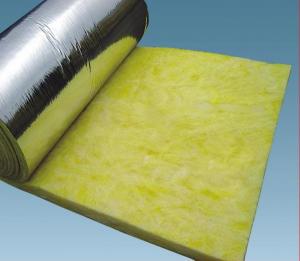

Glass Wool FSK Faced Blanket

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*40HQ pc

- Supply Capability:

- 100000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of Glass Wool Blanket

Glasswool board is a plate product with fixed strength after hot-setting the centrifugal glass wool. It has excellent thermal insurance performance at both high and low temperature environment.

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 20-100 |

Width | mm | 600-1 200 |

Length | mm | 1 200,2 400 |

Special product with special specification can be made to order.

Unfaced and faced felts are both provided

2. Application of Glass Wool Blanket

It is mainly used for the separating wall in the high-grade building, ceiling, air conduit or inner wall of bellows for thermal insurance, or machine shops for noise absorption, or metal ceiling for control of moisture. High density panels with laminated facing can be used for Air-Conditioning Duct System.

3.Package of Glass Wool Blanket

Normal packing: Each roll is wrapped with vacuum plastic bag, and then in PE woven bag.

Special required package like PE BAG and PE SHRINKED BAG can be made with additional charge.

- Q: What's the difference between the rock wool and glass wool?

- Glass wool: Main raw material is glass, A level fireproof grade, thermal conductivity coefficient 0.037, thermal shrinkage temperature 270 degrees, application: obvious cold insulation effect. Rock wool: Main raw material is glass, A level fireproof grade, thermal conductivity coefficient 0.040, thermal shrinkage temperature 730 degrees, application: It'd used in construction, ship building, petroleum chemical and other high-end engineering. hope it can help you.

- Q: If the glass wool is used for thermal insulation outside seamless steel tube, should the pipe be rust-proof and sprayed paint?

- That depends on the requirements. Brushing paint is needed. I an engaged in thermal insulation material wholesale and construction (see name).

- Q: Standard for the implementation of glass wool products

- Standard for the implementation of glass wool products

- Q: Glass fiber, glass wool, what is the difference

- Glass wool is the fibrous glass fiber, the formation of cotton-like material, chemical composition of glass, is a kind of inorganic fiber. Has a good shape, small density, thermal conductivity, thermal insulation, sound-absorbing performance, corrosion resistance , Chemical stability.

- Q: What's the types of glass wool points? do they have the same sound insulation effect?

- Rock wool and glass wool have poor sound insulation effect, and different prices, glass wool is easy for construction.

- Q: What harm dose glass fiber cotton do to human body?

- It may cause great harm to eyes and mucosa. Workers who are exposed to glass fiber for a long time may contract contact dermatitis, but some workers can gradually endure it, which is known as "hardening phenomenon".The degree of skin damage depends on fiber diameter and roughness of surface. For now it is widely recognized that only when the diameter exceeds 5μm, the fibre will be obviously irritative.Few workers who contact glass fiber and rock wool have skin allergies, but so far these fibers have not been confirmed to be sensitinogen.

- Q: Which is the more commonly used thermal insulation material between thermal insulation glass?silk wool and rock wool?

- Glass wool is a little better in that it has a lighter volume-weight than rock wool and better water-resistance ability, but it is more expensive than rock wool a lot of density, waterproof performance is better than lighter than wool to wool, but glass wool is more expensive in price per unit. In terms of fireproof effect, rock wool is definitely superior to glass wool. Rock wool has a maximum temperature of 1100 ℃, whereas glass wool has only 600 ℃. In addition, if used in the external walls, since glass wool has a limited volume-weight, which can merely reach at 60 to 90 in general, but rock wool have a volume-weight up to 140, so present-day external walls will not employ glass wool in general. Instead, rock wool is usually available because it is a A-level fireproof material. Glass wool is slightly lower than roock wool in thermal conductivity, while rock wool has longer fiber length. As for prices, glass wool per ton is more expensive than rock wool, but if the price is measured by per square, glass wool then is cheaper than rock wool.

- Q: What is the difference between glass wool and rock wool?

- What is the difference between glass wool and rock wool?

- Q: Why is glass wool board used in portable house on the construction site?

- Could it be that it is for fireproofing and prevention of burglary.

- Q: Which has better effect of sound absorption, glass wool or rock wool?

- Glass wool rock wool has a security risk. It is easy to pulverize, so it may cause pruritus and respiratory allergies. PANHOO gradient sound absorption wool is the best in currently market, which is eco=friendly, healthy, most efficient in full-frequency sound absorption.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 1999 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Southeast Asia;African |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Xingang; |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 1000,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Glass Wool FSK Faced Blanket

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*40HQ pc

- Supply Capability:

- 100000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords