Fiberglass Mat Tissue Glass Fiber Roving 2400 tex Glass Fiber Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Fiber Roving 2400 Tex Glass Fiber Roving Price

Introduction:

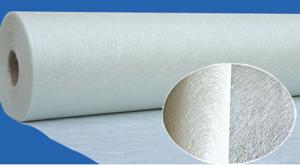

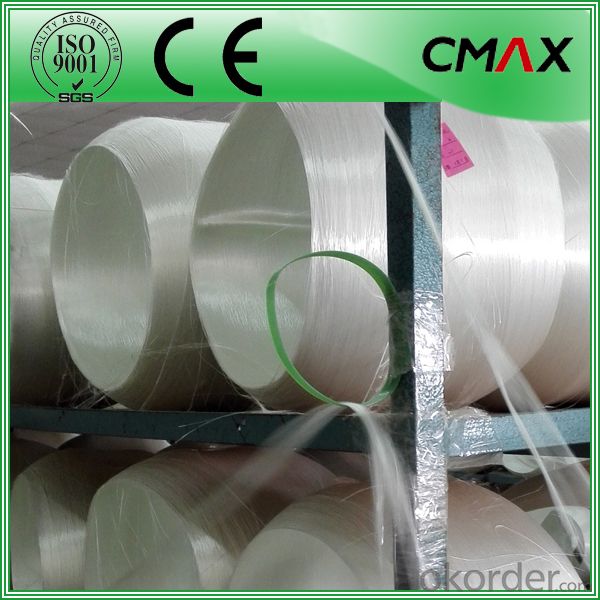

E-glass sprary-up roving, fiberglass gun roving, fiberglass roving is coated with a silance-based sizing, compatible with unsaturated polyester, vinyl ester and polyurethane resins.

It is a versatile general purpose spray-up roving used to manufacture boats, bathroom sinks ,yacht, sanitary ware, swimming pool and automotive parts and also pipe by centrifugal casting process.

Product Features:

1)Silane based coupling agent which delivers most balanced sizing properties.

2)Special sizing formulation which delivers good compatibility with martix resin.

3)Consistent fiber linear density,good mold ability and dispersion

4)Excellent mechanical properties of composite products

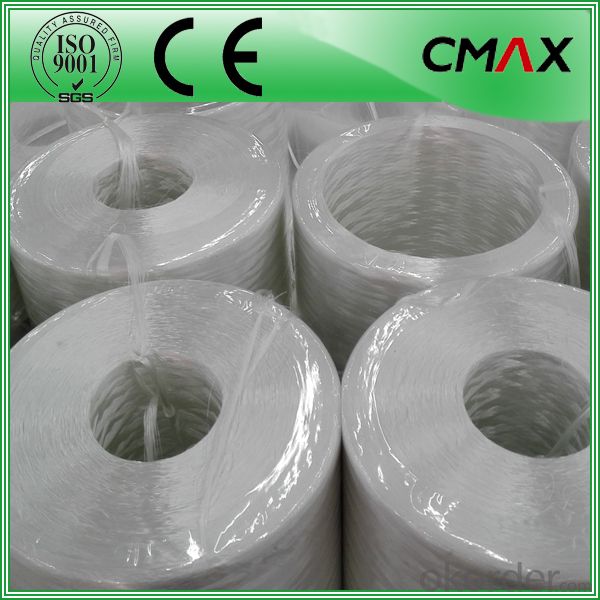

Packaging:

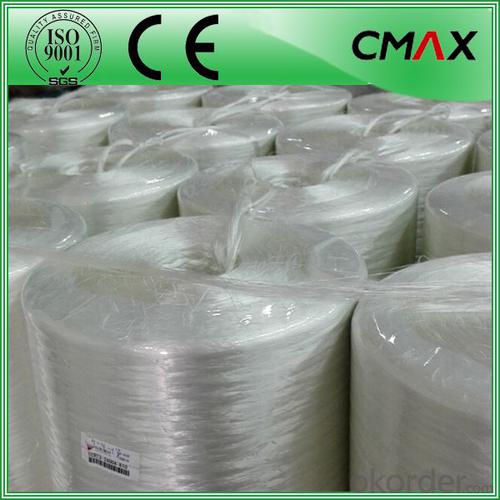

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

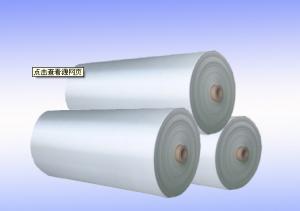

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: What are the common sizes available for fiberglass mat tissue?

- The common sizes available for fiberglass mat tissue vary, but typically range from 1.27 meters (50 inches) to 2.54 meters (100 inches) in width, and can be customized to desired lengths by manufacturers.

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass boats?

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass boats. Fiberglass mat tissue is a non-woven material made up of randomly oriented fiberglass strands held together by a binder. It is lightweight, flexible, and easy to work with, making it an ideal choice for reinforcing fiberglass boats. When used in boat construction, fiberglass mat tissue is typically used in conjunction with fiberglass resin to create a strong and durable composite material. The mat tissue is laid down and impregnated with resin, which then cures and hardens to form a rigid structure. This process helps to increase the strength, stiffness, and impact resistance of the boat. Fiberglass mat tissue is commonly used in areas that require additional reinforcement, such as the hull, deck, or other high-stress areas. It helps to distribute and absorb forces, reducing the risk of cracking or failure. Additionally, it can provide added protection against impacts and abrasions, helping to prolong the lifespan of the boat. However, it is important to note that fiberglass mat tissue alone may not be sufficient for reinforcing fiberglass boats. It is often used in combination with other reinforcement materials, such as fiberglass cloth or woven roving, to provide a balanced and optimized reinforcement system. Ultimately, the use of fiberglass mat tissue for reinforcing fiberglass boats can greatly enhance their structural integrity and durability. It is a versatile and cost-effective option that is widely used in the boat building industry.

- Q: Can fiberglass mat tissue be used for insulating concrete forms (ICFs)?

- Yes, fiberglass mat tissue can be used for insulating concrete forms (ICFs). It is commonly used as a reinforcement material in ICF construction due to its excellent insulation properties and ability to improve the overall strength and durability of the concrete structure.

- Q: Can fiberglass mat tissue be used for boat building?

- Yes, fiberglass mat tissue can be used for boat building. It is commonly used as a reinforcement material in boat construction due to its strength, durability, and ability to resist water damage.

- Q: Can fiberglass mat tissue be used for insulation in cold environments?

- Yes, fiberglass mat tissue can be used for insulation in cold environments. Fiberglass is a common material used for insulation due to its excellent thermal properties. It has a low thermal conductivity, meaning it can effectively resist the transfer of heat, thus providing insulation in cold environments. Fiberglass mat tissue is specifically designed to provide thermal insulation and is commonly used in applications such as walls, roofs, and floors to prevent heat loss and maintain a comfortable temperature indoors. Additionally, fiberglass is resistant to moisture and does not easily degrade or lose its insulating properties in cold and damp conditions, making it a suitable choice for insulation in cold environments.

- Q: Is fiberglass mat tissue resistant to fading?

- In general, fiberglass mat tissue tends to lack resistance against fading. Fading refers to the loss of original color or brightness in a material caused by exposure to sunlight or other environmental factors. Although fiberglass itself is known for its durability and ability to withstand weathering, the mat tissue used in fiberglass products often succumbs to fading over time. This can be attributed to both the binder or resin used to bind the fiberglass fibers together and the pigments or dyes used to color the tissue. When exposed to UV rays and other outdoor elements, these components can deteriorate and fade, resulting in a decrease in color intensity or brightness. Therefore, if maintaining the visual appeal of a fiberglass product is important, it may be necessary to take additional protective measures, such as applying a UV-resistant coating or using pigments specifically formulated for outdoor use.

- Q: Does fiberglass mat tissue require any special treatment for UV resistance?

- Special treatment is required for UV resistance when using fiberglass mat tissue. This tissue is composed of fine strands of glass fibers which can be easily damaged by prolonged exposure to ultraviolet (UV) radiation. The degradation of the fibers due to UV rays can result in a reduction in strength and dimensional stability. To enhance the UV resistance of fiberglass mat tissue, manufacturers often apply a unique coating or treatment to the material. This treatment serves to safeguard the fibers from UV radiation and prevent their deterioration. The specific treatment employed may vary based on the intended application and the desired level of UV resistance. Furthermore, it is important to acknowledge that despite the special treatment, fiberglass mat tissue may still experience some degree of UV damage over time. It is therefore advised to minimize direct sunlight exposure whenever possible to ensure the longevity and performance of the material.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- Yes, fiberglass mat tissue can be used for insulation in pharmaceutical storage areas. Fiberglass mat tissue is a versatile material that offers excellent thermal insulation properties. It is often used in various industries, including pharmaceuticals, due to its ability to regulate temperature and provide insulation against heat transfer. In pharmaceutical storage areas, maintaining the appropriate temperature is crucial to ensure the integrity and stability of stored medications and vaccines. Fiberglass mat tissue can help create a temperature-controlled environment by reducing heat transfer between different areas and protecting the stored products from external temperature fluctuations. Additionally, fiberglass mat tissue is lightweight, easy to install, and resistant to moisture, making it suitable for pharmaceutical storage areas where cleanliness and hygiene are essential. It can be easily placed between walls, ceilings, and floors to provide a barrier against heat flow, thus maintaining the desired temperature inside the storage area. Moreover, fiberglass mat tissue is a non-combustible material, which adds an extra layer of safety in pharmaceutical storage areas. It does not contribute to the spread of fire, ensuring the protection of valuable pharmaceutical products and reducing the risk of fire-related accidents. Overall, fiberglass mat tissue is an effective choice for insulation in pharmaceutical storage areas, providing thermal regulation, moisture resistance, cleanliness, and fire safety. It helps maintain the required temperature and ensures the integrity and stability of stored medications and vaccines.

- Q: What is fiberglass mat tissue made of?

- Fiberglass mat tissue is made of fine strands of glass fibers that are bonded together with a resin or binder material.

- Q: Can fiberglass mat tissue be used for making lightweight doors?

- Fiberglass mat tissue is a lightweight material commonly used in different industries due to its strength and durability. It consists of thin strands of fiberglass bonded together with a binder, resulting in a flexible and strong material. When utilized in door construction, fiberglass mat tissue offers multiple advantages. Firstly, its lightweight nature makes it perfect for creating doors that are easy to handle and install. This is particularly beneficial in residential or commercial settings where doors are frequently opened and closed. Moreover, fiberglass mat tissue possesses exceptional thermal and acoustic insulation properties. This means that doors made with this material can effectively block out noise and regulate temperature, resulting in a more comfortable and energy-efficient environment. Furthermore, fiberglass mat tissue is highly resistant to moisture, rot, and insects, making it a durable and long-lasting option for door construction. It can withstand harsh weather conditions, making it suitable for both interior and exterior doors. In conclusion, fiberglass mat tissue is a versatile material that can be used to create lightweight doors that offer strength, durability, insulation, and resistance to various environmental factors.

Send your message to us

Fiberglass Mat Tissue Glass Fiber Roving 2400 tex Glass Fiber Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords