E Glass Fiberglass Chopped Strand Mat with Fiberglass Facing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E glass Fiberglass Chopped Strand Mat Factory

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

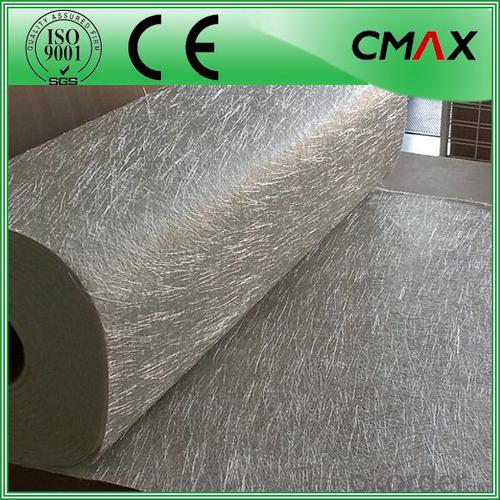

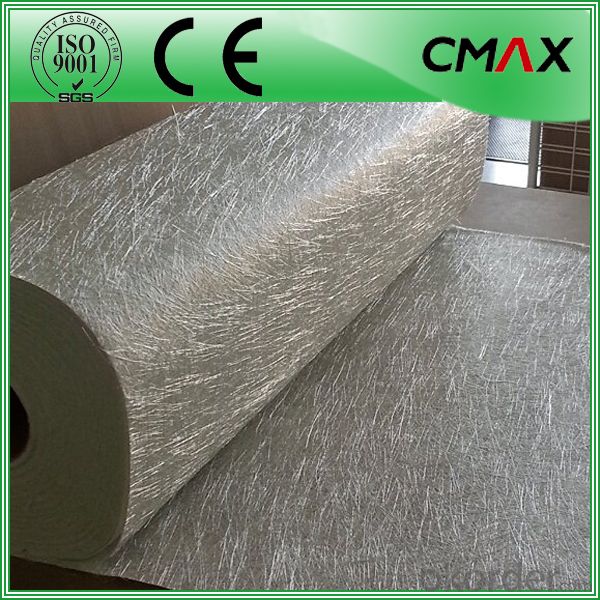

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: What distinguishes black fiberglass tissue from standard fiberglass tissue in terms of color, properties, and applications?

- <p>Black fiberglass tissue is a type of fiberglass material that has been treated to give it a black color, often through the addition of pigments or dyes. This coloration can enhance its aesthetic appeal in certain applications. It offers similar properties to regular fiberglass tissue, such as strength, durability, and heat resistance, but may have slightly different thermal properties due to the pigmentation. Regular fiberglass tissue is typically white or off-white and is used in a wide range of applications, including insulation, construction, and automotive parts. The choice between black and regular fiberglass tissue often depends on the specific requirements of the project, such as visual appearance, thermal efficiency, and cost.</p>

- Q: This question asks for guidance on selecting a dependable supplier for black fiberglass tissue, a material used in various industries.

- <p>To choose a reliable supplier of black fiberglass tissue, consider the following: Check their industry reputation and customer reviews. Ensure they have the necessary certifications and comply with industry standards. Evaluate their product quality by requesting samples. Assess their delivery times and reliability. Consider their customer service and after-sales support. Look for a supplier with a wide range of products to meet various needs. Finally, compare prices to ensure you're getting a fair deal without compromising on quality.</p>

- Q: This question asks if there is any difference between black fiberglass tissues that are domestically produced and those that are imported.

- <p>Yes, there can be differences between domestic and imported black fiberglass tissues. These differences may include quality standards, manufacturing processes, material composition, and cost. Domestic products are often more readily available and may be subject to local regulations and standards, while imported products might have different certifications or comply with international standards. Additionally, the cost can vary due to factors like transportation, import duties, and market demand. It's important to consider the specific application and requirements when choosing between domestic and imported black fiberglass tissues.</p>

- Q: Is it possible to utilize black fiberglass tissue in the construction industry?

- <p>Yes, black fiberglass tissue, also known as black fiber-reinforced polymer (FRP), can be used in construction. It is valued for its high strength-to-weight ratio, corrosion resistance, and durability. Black fiberglass is often used in reinforcing concrete structures, as a component in composite materials, and for strengthening or repairing existing structures. It is also used in the creation of lightweight and strong building materials, such as rebar replacements and for cladding due to its resistance to harsh weather conditions.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other organic fibers, focusing on their properties and applications.

- <p>Black fiberglass tissue, also known as black glass fiber, is an inorganic fiber made from glass that is often used for its strength and heat resistance. Compared to organic fibers such as cotton, wool, or silk, black fiberglass tissue is non-flammable, has a higher melting point, and offers superior insulation properties. It is also resistant to chemicals and does not rot or decay. However, it lacks the softness and breathability of organic fibers, making it less suitable for clothing. Organic fibers are biodegradable and more comfortable for direct contact with skin, but they are generally weaker and less heat-resistant than black fiberglass tissue.</p>

- Q: Is it safe to use black fiberglass tissues in a microwave oven?

- <p>No, you should not use black fiberglass tissues in a microwave oven. Black fiberglass can absorb microwaves and potentially cause sparks or a fire. It is recommended to use microwave-safe materials such as glass, ceramic, or microwave-safe plastic containers when heating food in a microwave. Always check the manufacturer's guidelines for the specific microwave-safe materials and avoid using anything that could be a fire hazard.</p>

- Q: Is it possible to utilize black fiberglass tissue as a flooring material in residential settings?

- <p>Yes, black fiberglass tissue can be used for flooring in residential homes. It is known for its durability, resistance to moisture and chemicals, and is often used in areas prone to water or chemical exposure. However, it may not be as aesthetically pleasing as traditional flooring options and can be slippery when wet, so it's important to consider these factors when deciding on its use for residential flooring.</p>

- Q: What is the tensile strength of black fiberglass paper, measured in terms of force per unit area?

- <p>The tensile strength of black fiberglass paper can vary depending on the specific type and manufacturer. Generally, it is known to have a tensile strength ranging from 100 to 200 MPa (megapascals). This high tensile strength makes it suitable for applications requiring durability and resistance to tearing, such as in electrical insulation and reinforcement in composite materials. It's important to check the specific product specifications for precise tensile strength values.</p>

- Q: What distinguishes black fiberglass from other types of glass fiber in terms of properties and applications?

- <p>Black fiberglass is a type of glass fiber that has been treated with a black pigment or dye, which gives it a distinct appearance and specific properties. Unlike other types of glass fibers which can be clear or have other colors, black fiberglass is primarily used for aesthetic purposes or to absorb light, reducing glare and reflections. It is often used in applications where a dark, non-reflective surface is desired, such as in some types of automotive components, exterior building materials, or in certain industrial settings. Other types of glass fibers may be used for their strength, insulation properties, or electrical non-conductivity, and are not necessarily colored. The choice between black fiberglass and other types of glass fibers depends on the specific requirements of the application in terms of appearance, performance, and functionality.</p>

- Q: This question asks about the cost of purchasing and installing black fiberglass tissue.

- <p>The cost of black fiberglass tissue can vary significantly based on several factors such as the quality, quantity, and the specific project requirements. On average, the material cost alone can range from $1 to $5 per square foot. Installation costs can add another $2 to $10 per square foot, depending on labor rates and complexity. For an accurate estimate, it's best to consult with a local supplier or contractor who can provide a quote tailored to your specific needs. Keep in mind that prices are subject to change and can differ by region and market conditions.</p>

Send your message to us

E Glass Fiberglass Chopped Strand Mat with Fiberglass Facing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords