Geotextile Sand Filter - Pet Continuous Filament Spunbond Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of PET Continuous Filament Spunbond Needle Punched Nonwoven Geotextile

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

5) Color: Black , white , grey and other color

6) Certificate: CE/ISO9001 , ISO14001

7) Manufacturing method: nonwoven / woven

8) The Biggest geotextile manufacturer/factory in China for many years

FAQ:

What is the main application of PET Continuous Filament Spunbond Needle Punched Nonwoven Geotextile ?

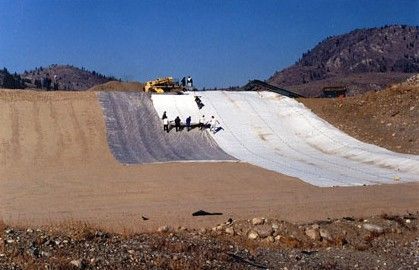

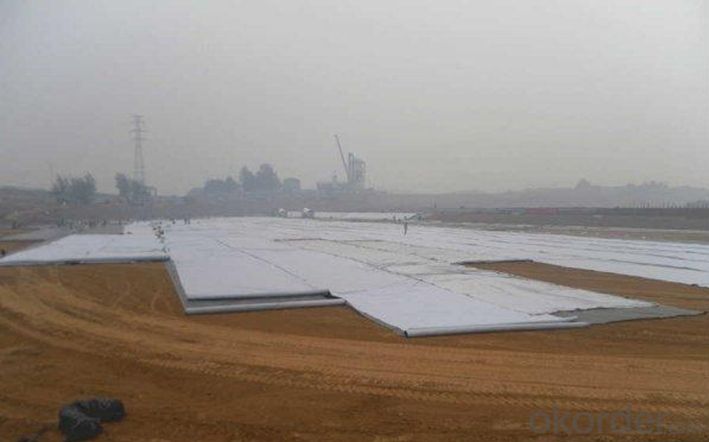

The main application of our PET Continuous Filament Spunbond Needle Punched Nonwoven Geotextile is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for PET Continuous Filament Spunbond Needle Punched Nonwoven Geotextile ?

One of the largest manufacturer of PET Continuous Filament Spunbond Needle Punched Nonwoven Geotextile for Construction with advanced equipment, big production capacity and excellent quality.

- Q: 400g / m2 two cloth a layer of water permeable geotextile technical requirements

- Two cloth a film will not be permeable, the composite film index breaking strength 5kn top broken 1.1kn tear 0.15kn peel 6n / cm or substrate fracture without stripping, the current 2008 standard weight has not been required, the original standard For not less than 360 grams

- Q: Geotextile with the welding tool where to buy

- Geotextile manufacturers, to buy geotextile belt welding machine

- Q: Can geotextiles be used in railway track stabilization?

- Yes, geotextiles can be used in railway track stabilization. Geotextiles are widely used in civil engineering projects to improve the stability, durability, and performance of the structures. In railway track stabilization, geotextiles can be placed beneath the ballast to prevent the mixing of finer particles with the ballast, reduce track settlement, and enhance the overall stability of the track. Additionally, geotextiles can also help in improving drainage and reducing the maintenance requirements of the railway track.

- Q: Today someone told me about a boyfriend, said to be geotextile. I wonder, geotextile cloth is what cloth? Is there there? Why is it used More

- Geotextile geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Divided into: non-woven geotextile, a textile geotextile (reinforced geotextile), warp knitted geotextile with demand can contact: Fang Lingyan Tel:

- Q: What are the key factors to consider when selecting a geotextile?

- The key factors to consider when selecting a geotextile are the intended application, the type and characteristics of the soil, the required strength and durability, and the desired drainage and filtration properties. Additionally, factors like installation methods, project budget, and environmental considerations should also be taken into account.

- Q: What are the different geotextile tensile strength test methods?

- There are several different geotextile tensile strength test methods, including the grab test, strip test, wide-width strip test, and trapezoid tear test. Each method has its own advantages and is used to evaluate the tensile strength and performance of geotextiles in different applications.

- Q: What are the design considerations for geotextile applications?

- Some design considerations for geotextile applications include the type and weight of the geotextile material, the strength and durability requirements, the expected level of permeability, the ability to withstand environmental conditions such as UV exposure or chemical exposure, and the compatibility with other materials used in the project. Additionally, factors such as installation methods, load distribution, and long-term maintenance should also be taken into account during the design process.

- Q: What are the considerations for geotextile selection in shoreline erosion control?

- There are several key considerations for geotextile selection in shoreline erosion control. First, the geotextile must have a high tensile strength to withstand the forces exerted by waves and currents. It should also be permeable to allow for water drainage and prevent the buildup of hydrostatic pressure. Additionally, the geotextile should be resistant to UV degradation and chemical exposure to ensure long-term durability. The choice of material and installation method should also take into account the specific site conditions, such as wave energy, sediment composition, and slope stability. Finally, cost and availability of the geotextile should be considered to ensure the solution is practical and feasible.

- Q: What is the difference between woven and non-woven geotextiles?

- Woven geotextiles are made by interlacing yarns or fibers together in a regular pattern, creating a strong and durable fabric. Non-woven geotextiles, on the other hand, are manufactured by bonding or felting fibers together, forming a random web-like structure. This results in a fabric that is less strong but offers excellent filtration and drainage properties. In summary, woven geotextiles are stronger and more suitable for applications requiring high tensile strength, while non-woven geotextiles are ideal for filtration and drainage purposes.

- Q: What are the specifications for geotextiles in stormwater management projects?

- The specifications for geotextiles in stormwater management projects vary depending on the specific requirements of the project. However, some common specifications include the type and thickness of the geotextile, its permeability, tensile strength, and durability. Additionally, the specifications may also outline the installation methods and quality control measures to be followed during the project.

Send your message to us

Geotextile Sand Filter - Pet Continuous Filament Spunbond Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords