Geotextile Samse Waterproofing Needle Punched Geotextile Membrane Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

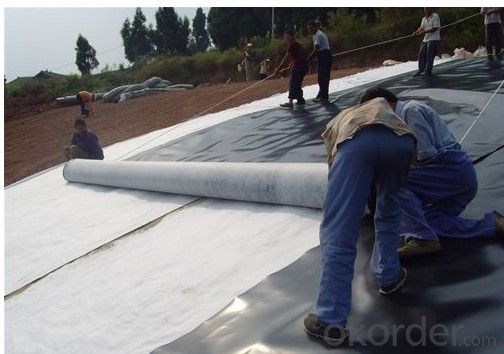

Product Introduction

Material: HDPE, LDPE

Thickness: 1mm-3mm

Width:4m-9m

Quality Inspection Standard: GB/T17643-1998

Quality Control Measure: strictly comply with ISO9001:2000

Have passed the CE certificate in Sep. 2008.

Features:

1) Can bear chemical erosion.

2) A wider using temperature range and a longer using life.

geomembrane hdpe

Geo-membrane is produced by a method of three layer co-extrusion model. The raw material is processed at 200°C by fusing and coextrusion, whose basic properties are kept during the producing process.

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the different installation guidelines for geotextiles in reinforcement projects?

- There are several guidelines to follow when installing geotextiles in reinforcement projects. Firstly, ensure that the subgrade is properly prepared and compacted before laying the geotextile. Next, carefully unroll the geotextile and secure it in place using stakes or by embedding it in the soil. It is important to overlap adjacent rolls of geotextile by at least one foot to ensure proper coverage. Additionally, avoid wrinkles or folds in the geotextile as they can reduce its effectiveness. Finally, cover the geotextile with a layer of soil or aggregate to protect it from damage and to provide additional reinforcement.

- Q: Are geotextiles suitable for use in stormwater management systems?

- Yes, geotextiles are suitable for use in stormwater management systems. They have proven to be effective in filtering sediment and pollutants from stormwater runoff, reducing erosion, and promoting infiltration. Geotextiles can enhance the performance and longevity of stormwater management systems by providing additional support, strength, and stability to the infrastructure.

- Q: Can geotextiles be used in landfill construction?

- Yes, geotextiles can be used in landfill construction. They are often used as a barrier or liner material to separate the waste from the underlying soil and prevent leachate from contaminating the surrounding environment. Geotextiles can also be used to reinforce the landfill slopes and prevent erosion.

- Q: How are geotextiles affected by UV exposure?

- Geotextiles are usually made of synthetic materials such as polypropylene or polyester, which can be negatively affected by prolonged exposure to UV radiation. UV exposure can cause degradation and weakening of the fibers, leading to reduced tensile strength and overall performance of geotextiles. To mitigate this, manufacturers often add UV stabilizers to enhance their resistance to UV radiation, thereby extending their lifespan and ensuring their effectiveness in various geotechnical applications.

- Q: Basically I'm thinking of doing a thesis defense on this topic and I want to know if it is any good.

- Any bio-degradable material is not a better substitute for a geotextile material in long run Materials from polymer family may suit better, like Polyamide Polypropylene Polyethylene My answer refers to about having the ability to separate, filter, reinforce, protect, or drain If your purpose of using geotextile material regarding Beach Erosion, Riverbank Erosion, then coconut fibers is a better option

- Q: What are the key factors affecting the clogging behavior of geotextiles?

- The key factors affecting the clogging behavior of geotextiles include the particle size and gradation of the soil or other material being filtered, the permeability and porosity of the geotextile, the hydraulic loading conditions, the presence of fines or clay particles in the soil, and the duration of exposure to clogging agents. Other factors such as the geotextile's physical and chemical properties, the presence of biological organisms, and the maintenance practices also play a role in determining the clogging behavior.

- Q: How do geotextiles help with groundwater protection?

- Geotextiles help with groundwater protection by acting as a barrier that prevents the movement of contaminants and pollutants from entering the groundwater. They are designed to filter and separate soil particles, allowing water to pass through while trapping harmful substances. Additionally, geotextiles can also enhance the stability and permeability of soil, reducing the risk of erosion and promoting proper drainage, which further aids in protecting the quality and quantity of groundwater.

- Q: How to calculate the volume weight of polypropylene nonwoven geotextile

- This is not necessarily to see the light of the needle or heavy.

- Q: Are geotextiles suitable for use in high-traffic areas?

- Yes, geotextiles are suitable for use in high-traffic areas. Geotextiles are durable and provide reinforcement and stabilization to the soil, making them ideal for use in areas with heavy foot or vehicle traffic. They prevent soil erosion, distribute loads, and increase the longevity of the pavement or surface, making them a reliable choice for high-traffic areas.

- Q: How do geotextiles improve the performance of embankments?

- Geotextiles improve the performance of embankments by providing reinforcement and stabilization. They distribute loads more evenly, preventing the embankment from settling or shifting. Additionally, geotextiles control erosion by allowing water to flow through while retaining soil particles, reducing the risk of slope failure.

Send your message to us

Geotextile Samse Waterproofing Needle Punched Geotextile Membrane Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords