Geotextile R63 PVC Foam Sheet, Plastic PVC Resin, PVC Extruded Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description:

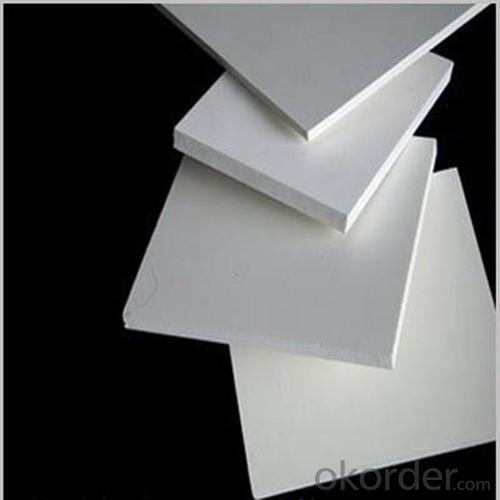

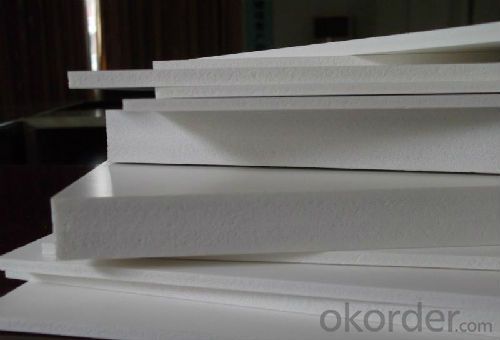

PVC Foam Sheet, a kind of high-tech product, is one product of Kingstar Plastic Sheet series. Through special machinery and technology processing, the main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as shinny or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

2.Application:

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

3.Feature:

1) UVprotected, Antichemical corrosion

2) Fire retardant and it can automatically extinguish by itself

3) Sound insulation, sound absorption, heat insulation and heat preservation

4) Moistureresistant, mildew proof, water repellent and shock proof

5) Nondeformation, agingresistant, color fastness for a very long time through particular formula

6) Light weight, easy and convenient for storage, transportation and using

7) It has a smooth and hard surface and is suitable for painting

4.Specifications:

1 | Product | PVC Foam sheet |

2 | Standard size | 1560mm × 3050mm |

3 | Thickness | 2mm-4mm |

4 | Density | 0.5g/cm3 |

5 | Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

6 | Executive standard | QB/T 2463.1-1999 |

7 | Certificate | ISO、SGS PONY Cetification |

8 | Weldable | Yes |

10 | Packing | Carton box or wooden pallet packing |

11 | production capability | 500000 pcs per month |

12 | Life Span | >50 years |

13 | Flame retardance | self-extinguishing less than 5 seconds |

5.RFQ

Q: If the products have some quality problem ,how will you deal with it?

A: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind. Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q: Could you provide samples?

A: Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

Q: Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.

Q: What factors affect the price?

A: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information to get exact quotation.

- Q: What are the different methods of geotextile installation?

- Some of the different methods of geotextile installation include trenching and backfilling, direct placement, and anchoring. Trenching and backfilling involves excavating a trench, laying the geotextile in the trench, and then backfilling it with soil. Direct placement involves simply placing the geotextile on the intended surface without any additional steps. Anchoring involves fixing the geotextile to the ground using various anchoring techniques such as stakes, pins, or sandbags. These methods can be chosen based on the specific project requirements and site conditions.

- Q: Can geotextiles be used in green roof applications?

- Yes, geotextiles can be used in green roof applications. Geotextiles are often used as a protective barrier or filter layer in green roofs to prevent soil erosion and aid in drainage. They can help retain moisture and provide stability to the growing medium, promoting healthy plant growth on green roofs.

- Q: Heap half a month later in the mound inside dug a tree tree hole, a heavy rain, a region which has two trees in the area of water, to several days of talent, which is normal, please expert advice, More

- Are you geotextile or composite film? Is your waterproofing layer ready? Do not leak?

- Q: The difference between the geotextile and the geotextile

- I professional production geotextile geomembrane and other geotechnical materials, a professional construction of the welding team, wish smooth

- Q: What are the advantages of using geotextiles in waste containment systems?

- Geotextiles offer several advantages in waste containment systems. Firstly, they act as a barrier, preventing the migration of pollutants and contaminants into the surrounding environment. This helps to protect groundwater and nearby ecosystems from potential harm. Additionally, geotextiles enhance the stability and structural integrity of waste containment systems, reducing the risk of failure or leakage. They also aid in the filtration and drainage of liquids, allowing for proper waste management and preventing the buildup of excess moisture. Overall, geotextiles provide an effective and environmentally-friendly solution for waste containment, ensuring safer disposal of waste materials.

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- The meaning of the protective layer and the isolation layer is not the same, figured out the role and meaning of nature know how to set up. 1, the protective layer of the waterproof layer contains a two-tier meaning. First, if there are other waterproof layer above the construction layer, due to the construction process may cause damage to damage to water, so need to do protective layer; Second, the roof is the function of the master or planting, the activities of personnel may cause damage to water , Need to do protective layer. 2, the role of the isolation layer is also divided into two kinds. First, to prevent the adverse effects of the two kinds of materials (incompatible), with the isolation layer for the interface, such as PVC coil and polystyrene foam insulation board, because the plasticizer in the membrane will migrate , The direct contact with the benzene plate will produce melt damage; Second, the coil surface of the rigid layer, may be due to thermal expansion and contraction deformation affect the waterproof layer, in the rigid layer of the larger part of the deformation, Too large and damage the waterproof layer, then need to set the isolation layer. There is a geotextile isolation layer between the waterproofing membrane and the pebble press material. 3, not all of the waterproof layer and the protective layer between the need for isolation layer. When the cement mortar is used as the protective layer, the cement mortar may be directly applied to the waterproof surface. When the flexible protective material (heat reflective coating, etc.) or the insulation layer is used, the isolation layer is not required.

- Q: How do geotextiles help with slope stabilization?

- Geotextiles help with slope stabilization by providing erosion control, reinforcement, and drainage. They act as a barrier to prevent soil erosion, retain soil particles, and allow water to drain through the fabric, reducing the buildup of excess water pressure. Additionally, geotextiles enhance the stability and strength of slopes by distributing loads and limiting soil movement, thus preventing landslides and slope failures.

- Q: How do geotextiles help with asphalt overlay?

- Geotextiles help with asphalt overlay by providing a stable and durable base for the new asphalt layer. They act as a barrier, preventing the mixing of the new asphalt with the existing pavement, which improves the overall strength and performance of the overlay. Additionally, geotextiles help in reducing reflective cracking and extending the lifespan of the asphalt overlay by distributing the load and reducing stresses on the pavement.

- Q: What are the materials used for spinning geotextiles?

- Spinning is made of synthetic fibers through acupuncture or weaving made of permeable geosynthetics. There are at least two sets of parallel yarns (or flat yarn), a group of looms along the loom (the direction of fabric travel) called warp yarns, another group The horizontal arrangement is called weft yarn.With the different weaving equipment and the process, the warp and the weft are woven together into a cloth, and can be knitted into different thickness and density according to different use range. Generally, the spinning and weaving cloth is thin and vertical Have a very strong tensile strength (longitude than latitude), with good stability. There are spinning geotextile according to the weaving process and the use of latitude and longitude is divided into reinforced geotextile and non-reinforced geotextile two categories, plus The tensile strength of the geotextile is much larger than that of the ordinary geotextile, and the general application of the geotextile is reinforced with the reinforcement of the geotextile project. The main function is reinforced by reinforcement and has the function of plane isolation and protection. Can be selected according to the specific purpose of use.

Send your message to us

Geotextile R63 PVC Foam Sheet, Plastic PVC Resin, PVC Extruded Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords