Plastic Sheets - PVC Foam Sheet for Advertisement, Extruded PVC Sheet Mould

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Size

Thickness range : 1mm -30 mm

Width max. : 2050mm

Length: Any length

Standard sizes:1220*2440mm 1560*2440mm 2050*3050mm

*We can also provide any other sizes according to your special needs.

Standard colors

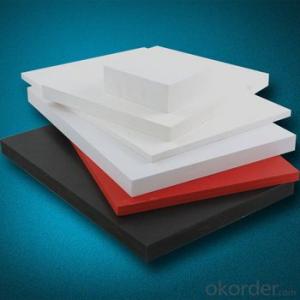

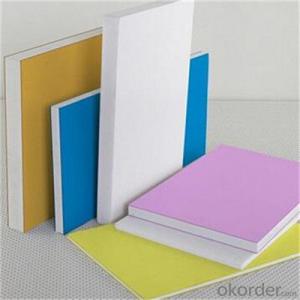

White,gray,blue,and other special colors

Characteristics

A new type of environmental protective plastic materials instead of woods and steels.

It is a flexible, economical, extremely versatile PVC-U sheet.

The fine cell structure and smooth surface finish makes it the preferred choice of professional printers and sign makers.

Light-weight, anti-flaming.Non-toxic.

Alkali &acid resistance, moisture proof, water-proof, good heat preservation, sound insulation, shock absorption and so on.

The board can be filmed or printed colorfully

It owns many ways of processing such as nailing, sawing, planning, cementing, jointing and so on.

Tough, rigid with the high impact strength.

Stable color retention

Pvc 1/2 inch high density foam sheet is made in a closed cell foam structure. This structure gives it the properties that make it useful as a material distinct from regular PVC plastics. Solid foam products are classified as being either open or closed cell. The open-celled foams have a system of tiny pores running throughout that are all connected to each other. These types of foam absorb liquids into the pore structure. Closed cell foam does not have pores that connect to each other.

PVC foam does not appear like many of the other foam products people are familiar with. Instead, it is almost always compressed into thin sheets that actually resemble cardboard more than larger and more pliant foam products. However, it is still a foam, it is just created in a foam board structure so that it can be cut and shaped easily while taking advantage of the strengths of the material.

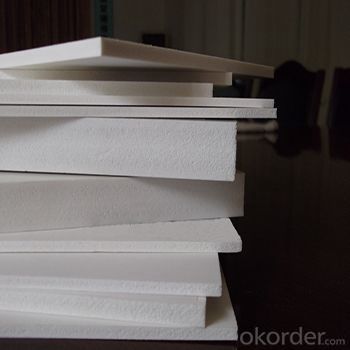

Pictures

FAQ:

Q1: Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

A: we are manufacturer specializing in stationery and plastic packing products in highly quality

and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,

packages of cosmetic and other daily necessities.

Q2: If the products have some quality problem ,how will you deal with it?

A1: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

- Q: How do plastic sheets handle extreme weather conditions?

- Plastic sheets are designed to be durable and resistant to extreme weather conditions. They can withstand high temperatures, heavy rain, strong winds, and even snow. However, prolonged exposure to extreme weather can cause some degradation over time, such as fading or brittleness. To ensure their longevity, it is important to choose high-quality plastic sheets and provide proper maintenance and protection, such as regular cleaning and UV-resistant coatings.

- Q: What are the advantages of using plastic sheets?

- There are several advantages to using plastic sheets. Firstly, they are lightweight and easy to handle, making them convenient for various applications. Additionally, plastic sheets are highly durable and resistant to impact, moisture, and chemicals, making them suitable for both indoor and outdoor use. They also offer excellent thermal insulation properties, helping to maintain desired temperatures. Moreover, plastic sheets are cost-effective compared to other materials, making them a cost-efficient choice for construction and packaging industries. Lastly, plastic sheets can be easily molded and customized to fit specific shapes and sizes, providing versatility in design and functionality.

- Q: Are plastic sheets resistant to weathering?

- Yes, plastic sheets are generally resistant to weathering. They are designed to withstand various weather conditions such as sunlight, rain, wind, and temperature changes. However, the degree of weather resistance may vary depending on the type and quality of the plastic used.

- Q: Put some drops of water on a glass or plastic sheet. After evaporation we seesome white spots like dust over?

- If I'm not mistaken, these white spots are actually caused by dust and dirt in the air that were caught by the water, and they are left behind after evaporation.

- Q: What are the advantages of plastic sheets?

- Plastic sheets have several advantages, including their durability, flexibility, and cost-effectiveness. They are resistant to impact, weather, and chemicals, making them ideal for various applications. Plastic sheets are lightweight and easy to handle, making installation and transportation convenient. Additionally, they offer excellent insulation properties, are easy to clean and maintain, and can be molded into different shapes and sizes to meet specific requirements.

- Q: Can plastic sheets be used for safety guards in manufacturing?

- Yes, plastic sheets can be used for safety guards in manufacturing. They are commonly used due to their durability, flexibility, and transparency, which allows for visibility and protection against various hazards in the manufacturing process.

- Q: Can plastic sheets be bent or folded?

- Yes, plastic sheets can be bent or folded.

- Q: Do plastic sheets have any insulating properties?

- Yes, plastic sheets can have insulating properties. They can act as a barrier to heat transfer, reducing the conduction of heat between two surfaces. However, the insulation effectiveness of plastic sheets can vary depending on their thickness, composition, and application.

- Q: do you put the picture under the plastic and put the plastic over it again and leave it?first time using photo sheet as an album thing, and usually i always seen the ones that are individual slots one.

- Yes, the photos are supposed to be under the plastic sheet for protection, while you look at them. Make sure the plastic sheets are of archival quality.

- Q: Can the toilet be covered with plastic buckles?

- PVC plastic buckle, water resistance, scrub resistance is very strong. It takes PVC as raw material, processed into the groove type profile, has the characteristics of light weight, easy installation, waterproof, moisture-proof, anti moth, its surface color pattern change very much, and resistant to pollution, easy cleaning, sound insulation, heat insulation performance is good, especially in the process of adding new flame retardant materials and make it from the fire that destroyed, use more safety.

Send your message to us

Plastic Sheets - PVC Foam Sheet for Advertisement, Extruded PVC Sheet Mould

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords