Geotextile HDPE Geomembrane Polyethylene Geomembrane Roll as Waterproof Facing of Earth in Bangladesh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

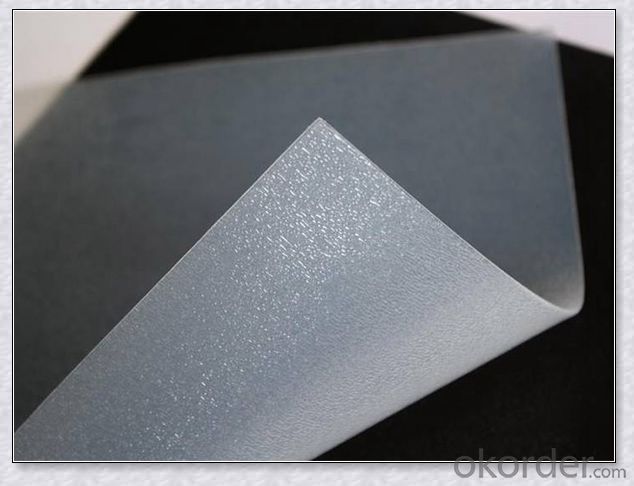

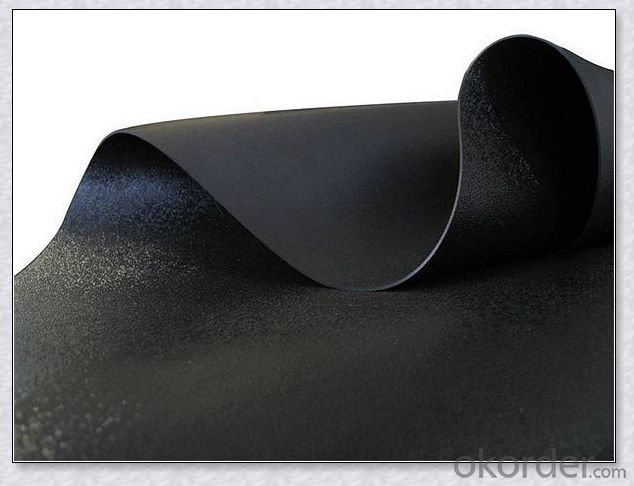

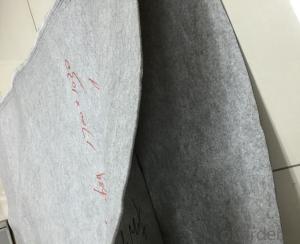

Photos:

Type:

Geomembranes

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

geomembrane

Material:

EVA, HDPE, LDPE, LLDPE, PVC

HDPE GEO Membrane

Our enterprise is a trustworthy manufacturer, exporter and supplier of HDPE GEO Membrane. This membrane is manufactured at our advanced manufacturing unit using avant-grade polymer resin and ultra-modern techniques under the guidance of our dexterous professionals. The membrane provided by us is used to control fluid migration in a human-made structures, project etc. In addition to this, the offered HDPE GEO Membrane can be availed with us at market leading rate.

Features:

Least permeability

Fine finish

Flexible

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Mainly on the cement concrete laying asphalt overlay and deck pavement, a bit puzzled, sticky words and how to design more

- Can be set together, geotextile in the lower layer can play a good pull, the role of protection!

- Q: What are the main functions of geotextiles?

- The main functions of geotextiles are to provide separation, filtration, reinforcement, and drainage in various civil engineering applications. They help prevent the mixing of different soil layers, enhance soil stability, control erosion, and allow for the efficient flow of water.

- Q: Can the tunnel longitudinal drains be wrapped with geotextiles and wrapped with a waterproof board?

- With geotextile wrapped drainage pipe is generally played the role of seepage drainage, do not need waterproof board (you said the waterproof board should be geomembrane it) Chong Hong geotextile material manufacturers

- Q: We are scrambling to sell geotextiles, recommended geotextile. What is the principle of geotextile seepage? Why can geotextile seepage? More

- Geotextile definition is too broad, and anti-seepage is mainly refers to the PE film

- Q: How do geotextiles help in preventing the loss of aggregate in unpaved roads?

- Geotextiles help in preventing the loss of aggregate in unpaved roads by acting as a barrier between the road surface and the underlying soil. They provide a stable and durable layer that prevents the aggregate from being displaced or eroded by the forces of traffic, water, and wind. This helps to maintain the integrity of the road and reduce maintenance costs.

- Q: Can geotextiles be used in oil and gas industry applications?

- Yes, geotextiles can be used in various oil and gas industry applications. They are commonly used in areas such as erosion control, filtration, dewatering, and soil stabilization. Geotextiles can help prevent soil erosion, protect pipelines from damage, and provide reinforcement in construction projects. They are versatile and cost-effective materials that offer numerous benefits in the oil and gas industry.

- Q: What are the factors to consider when selecting geotextiles for embankment stabilization?

- When selecting geotextiles for embankment stabilization, several factors should be considered. These include the strength and durability of the geotextile, its ability to withstand environmental conditions such as sunlight exposure and chemical degradation, its filtration and drainage properties, and its compatibility with the soil and other materials used in the embankment. Additionally, factors such as cost, installation requirements, and the specific project requirements and goals should also be taken into account.

- Q: U400 geotextile u400 what it means

- Is not 400g / ㎡ of geotextile? My company specializes in the production of geotextiles, details (hand) to see capital (machine) material

- Q: Unit of the quality of 400 geotextile piercing strong is generally how much? Hurry more

- First, geotextile polyester staple fiber geotextile (PET) and polyester filament geotextile two. Two kinds of geotextile anti-puncture strong (should be CBR burst strong) different. Polyester staple geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester staple geotextile CBR burst strength ≥ 2.1KN. Polyester filament geotextile in accordance with the national standard GB / T-2008 standard implementation, 400g GB polyester filament geotextile CBR burst strength ≥ 39KN. 400g GB polyester staple geotextile longitudinal and horizontal tear strength ≥ 0.33KN, 400g GB polyester filament geotextile longitudinal and horizontal tear strength ≥ 0.56KN.

- Q: Can geotextiles be used in green roof construction?

- Yes, geotextiles can be used in green roof construction. Geotextiles are commonly used as a separation layer between the growing medium and the drainage layer in green roofs. They help prevent the migration of fine particles into the drainage layer and maintain proper water flow within the system. Additionally, geotextiles can enhance root penetration and overall stability of the green roof.

Send your message to us

Geotextile HDPE Geomembrane Polyethylene Geomembrane Roll as Waterproof Facing of Earth in Bangladesh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords