Geotextile Fabric Roll for Polyester Geogrid Hill Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Polyester Geogrid for Hill Slope Reinforcement:

Product Introduction:

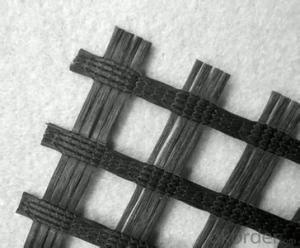

1. High tensile strength;

2. Low elongation ratio;

3. Anti-erosion and anti-aging;

4. Strong combination with gravel and soil;

5. Being light and has drainage effect.

Main Features of Polyester Geogrid for Hill Slope Reinforcement:

The road should be levelled and cleaned before construction at first. Then the geogrid should be laid on the coarse stone of asphalt layer. If customers use normal geogrid, they need specific steel-nail to fix geogrid joints. The intersections should be bigger then the size: 5cm on the horizontal direction and 10cm on the vertical direction. It’s better to spill the least asphalt adhesive oil. If customers use self-adhesive geogrid, they can pave and compact asphalt mixture after crushing of tyre-wheels roller, and there’s no need to fix with specific steel-nails.

Specifications of Polyester Geogrid for Hill Slope Reinforcement:

Short fiber nonwoven geotextile technical data

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Applications of Polyester Geogrid for Hill Slope Reinforcement:

1. It mainly applied on strengthening soft ground of road, railway and municipal road. It can improve the strength of foundation effectively, and prevent road cracking.

2. Polyester geogrid is widely used on enforcement and isolation of damsand rivers in hydraulic projects. It can strengthen the soft soil foundation, enhance the protective ability and improve the bearing capacity and stability of foundation.

3. Polyester geogrid is applied on the enforcement of embankement, slope and retaining wall to strengthen the overall intensity. It’s used on the enhancement of soft soil of road, railway and hydraulic projects.

4. Warp knitted polyester geogrid is used on railway ballast protection. Because of the train vibration and weather factors, the ballast will lose greatly. Wrapping ballast with geogrid can prevent ballast loss and improve the stability of foundation.

5. The product is used on railway retaining wall, for example the goods pallet to prolong the lifespan and reduce maintenance costs.

6. It’s applied on enforcement of retaining wall: highway and vertical wall with polyester geogrid could improve the bearing capacity of retaining wall.

7. The abutment foundation is easy to sink. Applying polyester geogrid under abutment foundation can improve the bearing capacity stability.

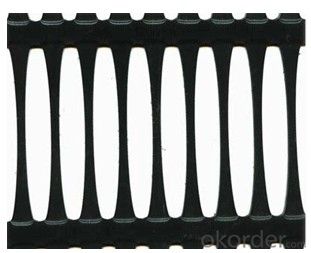

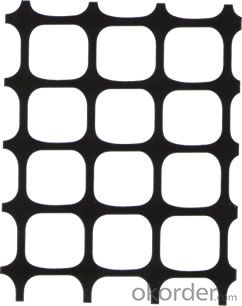

IMages of Polyester Geogrid for Hill Slope Reinforcement:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: A creek next to our property is eating away the embankment and an engineer suggested using the sand in the creek bed.. wrapping it up in geotextile fabric in the form of a burrito but he did mnot mention how to fasten them shut..any ideas or experience with erosion control out there?

- Get some tie wire or baling wire. It's a soft wire used for tying reinforcing steel together or for baling straw. You could also use plastic cable ties.

- Q: How do geotextiles help with sediment control in construction sites?

- Geotextiles are used in construction sites to help with sediment control by acting as a barrier that traps sediment and prevents it from being washed away by water runoff. These permeable fabrics allow water to pass through while retaining the sediment, reducing erosion and preventing pollution of nearby water bodies.

- Q: Geotextile Model PP200-4-750 What does it mean?

- Is the geotextile 200g / ㎡? Geotextile is generally based on the weight per unit area to divide the specifications. Geotextile manufacturers Zhang Ming Chao for you to answer, I hope to help you.

- Q: What are the different geotextile installation techniques for landfill applications?

- There are several geotextile installation techniques commonly used for landfill applications. These include the direct placement method, the trench method, the soil cover method, and the liner method. The direct placement method involves placing the geotextile directly on the subgrade or waste material, while the trench method involves placing the geotextile in a trench and then covering it with soil. The soil cover method involves placing the geotextile on top of the waste material and then covering it with a layer of soil. The liner method involves placing the geotextile on top of a geomembrane liner to provide additional protection and support. Each method has its own advantages and considerations depending on the specific requirements of the landfill site.

- Q: Can geotextiles be used for slope stabilization?

- Yes, geotextiles can be used for slope stabilization. Geotextiles are commonly used in slope stabilization projects to reinforce the soil, control erosion, and provide structural support. They can help improve the stability and strength of slopes by preventing soil movement, promoting vegetation growth, and distributing loads evenly.

- Q: How are geotextiles affected by chemical exposure?

- Geotextiles can be negatively affected by chemical exposure, as certain chemicals can degrade the material and reduce its effectiveness. The specific impact will depend on the type and concentration of the chemical, as well as the composition and quality of the geotextile. Regular monitoring and selection of chemically resistant geotextiles can help mitigate the potential damage caused by chemical exposure.

- Q: How do geotextiles help with reinforcement of geotextile bags?

- Geotextiles help with the reinforcement of geotextile bags by providing strength and stability to the bags. They act as a barrier and prevent the soil or other fill material from escaping through the pores of the bags. Additionally, the geotextiles distribute the weight of the fill material evenly, reducing the risk of bulging or bursting of the bags.

- Q: How do geotextiles contribute to soil stabilization?

- Geotextiles contribute to soil stabilization by providing a barrier that prevents soil erosion, increases soil strength, and improves overall stability.

- Q: How do geotextiles help with soil stabilization?

- Geotextiles help with soil stabilization by providing a barrier that separates the soil layers, preventing them from mixing and maintaining their structural integrity. This prevents erosion, improves drainage, and enhances the overall stability of the soil, reducing the risk of slope failure and ensuring long-term stability of the area.

- Q: What are the different geotextile weight classes and their applications?

- Geotextile weight classes range from lightweight to heavyweight, typically categorized as classes 1 through 5. Class 1 geotextiles are lightweight and used for erosion control, filtration, and separation in landscaping and gardening projects. Class 2 and 3 geotextiles are medium-weight and commonly used for road construction, pavement reinforcement, and drainage applications. Class 4 geotextiles are heavy-duty and suitable for shoreline protection, slope stabilization, and landfill lining. Lastly, Class 5 geotextiles are the heaviest and used in geotechnical engineering for applications such as soil stabilization, embankment reinforcement, and railway construction.

Send your message to us

Geotextile Fabric Roll for Polyester Geogrid Hill Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords