Geotextile Cells Anti-Skid Needle Punched Non Woven Geotextile with High Strength Cmax

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Application of Geotextile

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

Specifications:100GSM-1500GSM

length:50m-100m

width:1m-8m

material:100%PET

Packaging Details: pp woven bags or at your request

Delivery Detail: 15 days

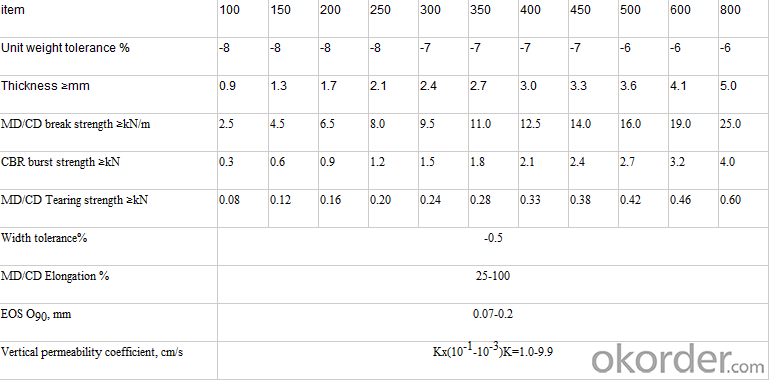

Technical Specification

Packing

FAQ

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with soil confinement in erosion control bags?

- Geotextiles help with soil confinement in erosion control bags by providing a permeable barrier that retains the soil particles while allowing water to pass through. They prevent soil erosion by reinforcing the bags and stabilizing the soil, preventing it from being washed away by water or wind.

- Q: What are the factors affecting the selection of geotextiles?

- The factors affecting the selection of geotextiles include the specific application or project requirements, such as the desired strength, durability, and permeability of the geotextile. Other factors include the site conditions, including soil type, slope stability, and water conditions. Additionally, the cost, availability, and environmental considerations of the geotextile should also be taken into account during the selection process.

- Q: Mainly on the cement concrete laying asphalt overlay and deck pavement, a bit puzzled, sticky words and how to design more

- Stress absorption layer thickness greater than 4cm, geotextile in the next, the stress absorption layer thickness of less than 4cm, geotextile on the

- Q: Long-term exposure to geotextiles on the human body what harm?

- Geotextile material is mostly polyester, and the essence of polyester clothes the same. There are mineral water bottle material is also PET polyester polyester sheet. Polyester has been widely used in our lives, no radiation, no pollution, no poison. Long-term close contact with the geotextile on the body without injury. So you do not have to worry.

- Q: Alteration of highway seepage control geotextile is generally placed in what position

- Apply to the grassroots level of water defense, the use of embedded, covered with thickness should not be less than 30CM, soil to be solid, to avoid uneven subsidence, cracks. Lap width should be greater than 15CM.

- Q: How do geotextiles contribute to soil reinforcement in embankments?

- Geotextiles contribute to soil reinforcement in embankments by providing a stable and reinforced base for the soil. They act as a barrier, preventing soil erosion and maintaining the integrity of the embankment. The geotextiles distribute the load across a wider area, reducing the stress on the soil and preventing settlement. Additionally, they enhance the overall stability of the embankment by increasing its resistance to lateral forces and promoting better drainage.

- Q: How are geotextiles used in railway construction?

- Geotextiles are commonly used in railway construction for various purposes such as erosion control, filtration, separation, and reinforcement. These synthetic fabrics are placed in different layers beneath the railway tracks to provide stability, prevent soil erosion, and improve drainage. They also help to separate and reinforce different layers of soil, preventing intermixing and maintaining the overall integrity of the tracks. Overall, geotextiles play a crucial role in enhancing the performance and longevity of railway infrastructure.

- Q: Can the roof waterproof with geotextiles?

- It is generally believed that the individual geotextile does not have the anti-seepage effect, the main assessment index is the permeability coefficient, the general geotextile coefficient is higher than the ordinary soil, about 0.01-0.001 look, but geotextiles and rubber, Asphalt, plastic will form a combination of impermeable composite, anti-seepage effect increased by 10 times, and asphalt, rubber combined into a waterproof

- Q: What is the price per square of the non-woven polyester fabric? What is the difference between the geotextile used in the building?

- The price of non-woven polyester fiber cloth is by weight per tonne, higher than the melting point of commonly used geotextiles, strong indicators are also high, longer service life. Building commonly used polyester short wire acupuncture geotextile its strong indicators of low, the price is low.

- Q: Can geotextiles be used in underground pipe installation?

- Yes, geotextiles can be used in underground pipe installation. Geotextiles are often used as a protective barrier between the pipe and surrounding soil to prevent soil intrusion, enhance drainage, and provide additional support.

Send your message to us

Geotextile Cells Anti-Skid Needle Punched Non Woven Geotextile with High Strength Cmax

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords