Geogrids Husker Nutrition Geotextile for Greening White

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nutrition geotextile in water environmental engineering .

Specification:

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway ,highway, movement hall,Dams,hydraulic structures hence hole, coastal shoal, reclamation,environmental protection and other projects. The main products are Synthetic staple fibers needle punched nonwoven geotextiles and split film yarn woven geotextiles.

Product Feature:

1. Simple and fast construction

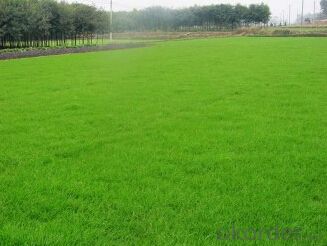

2. Achieve the greening effect quickly after construction

3. Due to the grass and composite fiber fabrics become into one integration, so it has the ability of certain degree of flow resistance for the water rising before the grass survive.

4. Composite fiber fabric is a continuous structure from slope top to slope toe, both ends are fixed, has high water flow resistance.

Technical Specification

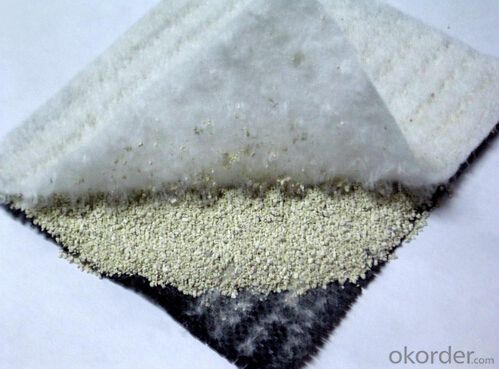

5.0 m length and 1.05 m width. Reverse side all used filter material. Grass seeds: Bermuda grass (warm season grass), Bahia grass (warm season grass), Kentucky bluegrass (cold season grass), Tall fescue grass (cold season grass), Red fescue grass (cold season grass). Plant height: 0.1 ~ 0.5 m.

| NO. | Items | Specification | Notes | |||

| 1 | Total unit area weight g/sq.m | ≥380 | ||||

| 2 | dimension | width m | 1.0~2.0 | |||

| length m | as per user’s request | |||||

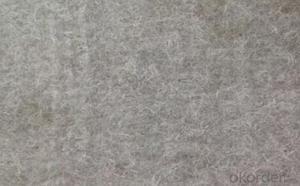

| 3 | Composite fiber fabrics | Material | Polyester Fiber | High strength PET | ||

| Unit area weight g/sq.m | ≥160 | |||||

| Mesh dimension mm | 8×8 | |||||

| Extension strengh kn/m | ≥11 | MD & CD | ||||

| 4 | Filtra layer | Material | Polyester non woven geotextile | |||

| Unit area weight g/sq.m | ≥40 | |||||

| 5 | Grass seeds, Fertilizer | Type | According to actual situation choose 3~5 grass seeds | |||

| Plant height m | 0.1~0.3 | |||||

| 6 | Fiber layer | Material | wood pulp cellulose | |||

| Unit areaweight g/sq.m | ≥15 | |||||

| 7 | flow resistance | ≥4 | not allow appear scour, suction and blanket turn-over etc. damage phenomenon | |||

| M/s | ||||||

| 8 | Anti-UV strengh conservation rate % | 65~80 | 3000hrs Continuously exposure 3000hrs | |||

| 9 | Supporting spare parts | ABS fastening nail | Material | ABS Resin | Fixed between two blankets by length direction | |

| Fiber diameter mm | 35 | |||||

| Nail length mm | 325 | |||||

| Lnail | Material | Steel wire (content 10% zinc-aluminium alloy) | Used to fix single blanket | |||

| Fiber diameter mm | 4 | |||||

| Nail length mm | 200 | |||||

| ABS connecting nail | Material | ABS Resin | Used in the slope between the two blankets ( width direction) | |||

| Nail length mm | 38 | |||||

| Connecting fiber | Material | High strength Polypropylene | Used in the slope between the two blankets ( width direction) | |||

| Length mm | Cut as per request | |||||

APPLICATION:

Generally laid on the river channel, slope protection etc. slope revetment projects, to control the water erosion, soil loss, meantime can reach the effect of slope ecological restoration and landscape greening, making river back to natural.

- Q: Are geogrids fire-resistant?

- No, geogrids are not typically fire-resistant.

- Q: What are the factors that affect the performance of geogrids under cyclic loading?

- Some factors that can affect the performance of geogrids under cyclic loading include the type and quality of the geogrid material, the installation method, the magnitude and frequency of the cyclic loading, the soil conditions, and the presence of any additional reinforcement or confinement.

- Q: Technical specifications of glass fiber grating

- (kN/m) by 30506580506580 to 30506580506580 weft elongation (%) = 3 = 3 = 3 = 3 = 3 = 3 = 3 mesh size (mm*mm) 25.4 x 25.4 x 25.4 x 25.4 x 25.4 25.4 25.4 25.4 12.7 12.7 12.7 x 12.7 x 12.7 x 12.7 elastic modulus (Gpa) 67676767676767

- Q: Tgsg5050 what is the difference between Geogrid and gsz5050?

- "Bi directional tgsg30-30 geogrid" is a specification for biaxial tensile plastic geogrid

- Q: Can geogrids be used in stabilization of mine waste dumps?

- Yes, geogrids can be used in the stabilization of mine waste dumps. Geogrids are commonly used in civil engineering to reinforce and stabilize soil structures. By placing geogrids within the mine waste dump, it helps to prevent the material from shifting or sliding, providing stability and reducing the risk of slope failures. Additionally, geogrids also improve the overall strength and load-bearing capacity of the dump, promoting long-term stability and preventing erosion.

- Q: What is the recommended geogrid aperture size?

- The recommended geogrid aperture size depends on various factors such as the type of soil and the intended application. It is best to consult with a geotechnical engineer or refer to specific industry standards and guidelines to determine the appropriate geogrid aperture size for a given project.

- Q: What is the lifespan of geogrids in typical applications?

- The lifespan of geogrids in typical applications can vary depending on various factors such as the specific type and quality of the geogrid, the environmental conditions, and the level of stress or load applied to the geogrid. However, in general, geogrids are designed to have a long lifespan ranging from 20 to 50 years or even more in some cases. Regular maintenance and inspection can help extend the lifespan of geogrids and ensure their continued effectiveness in their intended applications.

- Q: How do geogrids help in reducing the carbon footprint of a project?

- Geogrids help in reducing the carbon footprint of a project by providing a sustainable and environmentally-friendly solution for soil stabilization and reinforcement. By using geogrids, less excavation and material are required, reducing the need for transportation and minimizing energy consumption. Additionally, geogrids can extend the lifespan of infrastructure, reducing the need for frequent repairs and replacements, which further reduces carbon emissions associated with construction.

- Q: What are the factors affecting the durability of geogrids?

- The factors affecting the durability of geogrids include the material composition of the geogrid, the quality of the manufacturing process, exposure to UV radiation, chemical exposure, temperature fluctuations, installation techniques, and the level of stress or load placed on the geogrid.

- Q: Can geogrids be used in ground reinforcement for airports?

- Yes, geogrids can be used in ground reinforcement for airports. Geogrids are commonly employed in the construction industry to reinforce and stabilize soil, including areas with heavy traffic such as airports. They can effectively distribute loads and improve the strength of the ground, ensuring the stability and durability required for airport infrastructure.

Send your message to us

Geogrids Husker Nutrition Geotextile for Greening White

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords