Geogrids Husker HDPE Uniaxial Geogrid with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

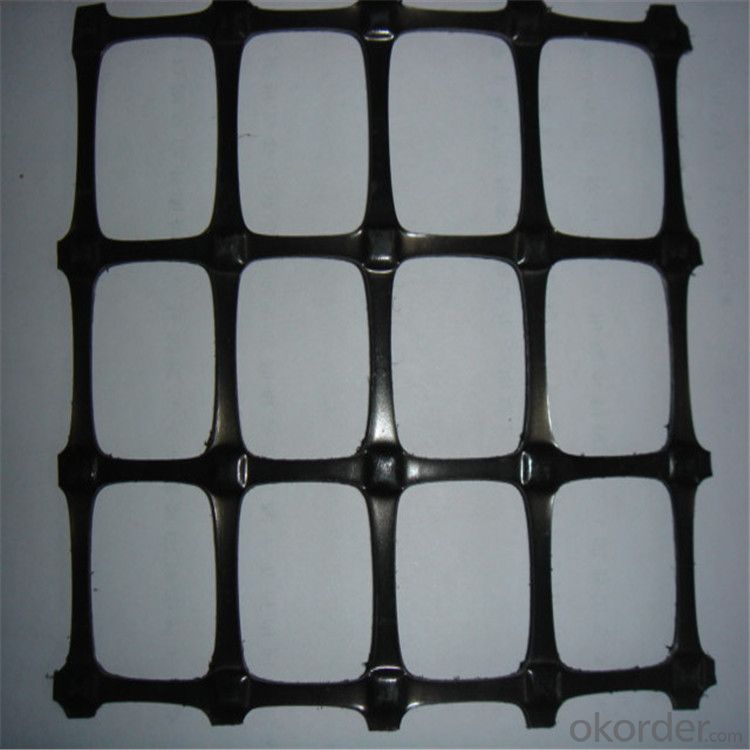

Product Specification---HDPE UniaxialGeogrid

Introduction:

HDPE Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched

into regular mesh pattern, and finally stretched in the longitudinal direction.

Features:

With high tensile strength and tensile modulus

Application:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1) strengthen land loading capacity

and extend its service life.

2) convenient to construct ;

reducing area , project cost and maintenance cost.

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

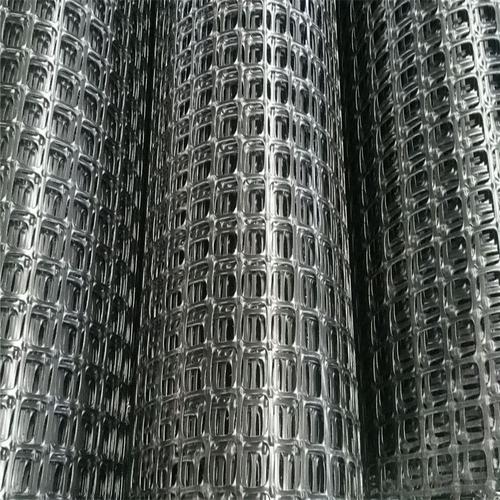

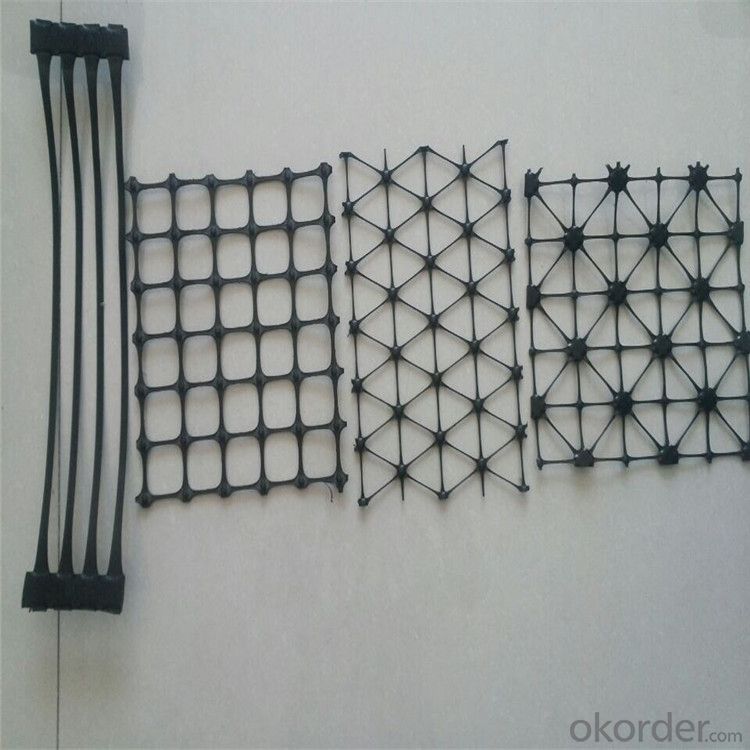

Images of HDPE Biaxial Geogrid

- Q: Are geogrids resistant to seismic forces?

- Yes, geogrids are resistant to seismic forces. Geogrids are made of strong materials like polyester or polypropylene, which provide high tensile strength and resistance to stretching. These characteristics allow geogrids to effectively withstand and distribute seismic forces, making them a reliable solution for reinforcing soil in areas prone to earthquakes.

- Q: Geogrid and geotextile, the role is the same?

- In short, the role of geogrid is to stabilize the roadbed, extend the service life of the road

- Q: What is the effect of creep rupture on geogrid performance?

- Creep rupture can significantly impact the performance of geogrids. Geogrids are engineered materials commonly used in civil engineering applications to reinforce soil and provide stability. Creep rupture refers to the gradual deformation and eventual failure of a material under constant load over time. When geogrids experience creep rupture, their structural integrity is compromised, leading to reduced performance and potential failure. The creep rupture phenomenon can cause the geogrids to elongate, lose their load-bearing capacity, and exhibit increased deformation under sustained loads. This can result in the geogrids being unable to effectively reinforce the soil, leading to soil settlement, slope instability, or even structural collapse. To ensure optimal geogrid performance and prevent creep rupture, it is crucial to select geogrids with high creep resistance and proper design considerations. Regular monitoring, maintenance, and periodic inspections are essential to identify signs of creep rupture and address any potential issues promptly.

- Q: Are geogrids effective in preventing soil erosion around pipelines?

- Yes, geogrids are effective in preventing soil erosion around pipelines. Geogrids provide structural support and reinforcement to the soil, preventing it from eroding and destabilizing around the pipelines. They help distribute the load and reduce the potential for soil movement, ensuring the stability and longevity of the pipeline infrastructure.

- Q: What is geogrid, what is the role?

- Glass fiber geogrid is a way used to enhance, reinforcement, reinforcement of excellent geosynthetic materials of soft soil subgrade. And in the treatment of asphalt pavement reflection crack applications, has become the indispensable materials. The product is made of high strength alkali free glass fiber through international advanced knitting process made of mesh substrate. Semi rigid products by surface coating processing and made with warp and weft two-way high tensile strength and low elongation, and high temperature resistance, low temperature, aging resistance, corrosion resistance and other excellent properties, is widely used in the asphalt pavement, cement concrete pavement and subgrade reinforcement and railway roadbed, dam slope protection, airport runway, sand project.

- Q: The difference between geocell and geogrid

- The geocell is a kind of three-dimensional grid chamber structure, which is formed by the high strength welding of the HDPE material. Generally welded by ultrasonic needle. Due to the need of the project, some of them are punched on the diaphragm.

- Q: How do geogrids enhance the stability of mechanically stabilized earth walls?

- Geogrids enhance the stability of mechanically stabilized earth walls by providing reinforcement to the soil and distributing the load more evenly. They increase the tensile strength of the wall, preventing the soil from sliding or collapsing under pressure. Additionally, geogrids improve the overall performance and longevity of the wall by minimizing deformation and settlement.

- Q: Can geogrids be used in bridge abutments?

- Yes, geogrids can be used in bridge abutments. Geogrids are commonly used in soil stabilization and reinforcement applications, and they can be effectively used to improve the stability and strength of bridge abutments. By installing geogrids in the soil surrounding the abutments, the geogrids can distribute loads more evenly, prevent soil erosion, and provide additional support to the bridge structure.

- Q: How is a geogrid different from other geosynthetics?

- A geogrid is a type of geosynthetic that differs from other geosynthetics in its primary function and structural design. Unlike geotextiles or geocomposites that are primarily used for separation, filtration, or drainage purposes, geogrids are specifically designed to provide reinforcement and stabilization to soil and other materials. Geogrids are typically made of high-strength polymers and have a grid-like structure with open apertures, allowing them to interlock with soil particles and distribute loads more effectively. This unique design enables geogrids to enhance the mechanical properties of soils, increase their bearing capacity, and improve overall stability in various civil engineering applications.

- Q: Are geogrids suitable for use in mechanically stabilized embankments?

- Yes, geogrids are suitable for use in mechanically stabilized embankments. Geogrids are widely used in such applications due to their high tensile strength and reinforcement capabilities. They help distribute loads, reduce settlement, and increase the stability of embankments.

Send your message to us

Geogrids Husker HDPE Uniaxial Geogrid with High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords