Geogrids Fort McMurray Nutrition Geotextile for Greening Various Sizes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Nutrition geotextile in water environmental engineering .

Specification:

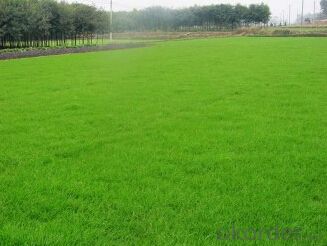

1. It is specialized made for greening concrete

2. Provide nutrits for plants and keep moisture

3. Easy to construct

Product Feature:

1. Simple and fast construction

2. Achieve the greening effect quickly after construction

3. Due to the grass and composite fiber fabrics become into one integration, so it has the ability of certain degree of flow resistance for the water rising before the grass survive.

4. Composite fiber fabric is a continuous structure from slope top to slope toe, both ends are fixed, has high water flow resistance.

Technical Specification

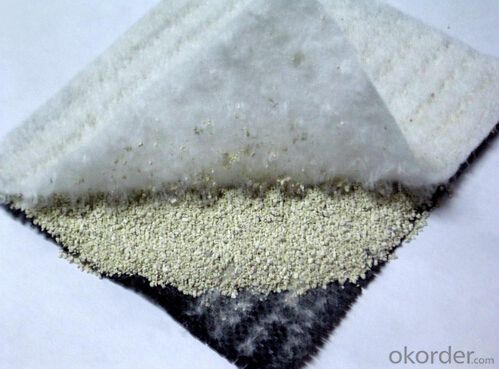

5.0 m length and 1.05 m width. Reverse side all used filter material. Grass seeds: Bermuda grass (warm season grass), Bahia grass (warm season grass), Kentucky bluegrass (cold season grass), Tall fescue grass (cold season grass), Red fescue grass (cold season grass). Plant height: 0.1 ~ 0.5 m.

| NO. | Items | Specification | Notes | |||

| 1 | Total unit area weight g/sq.m | ≥380 | ||||

| 2 | dimension | width m | 1.0~2.0 | |||

| length m | as per user’s request | |||||

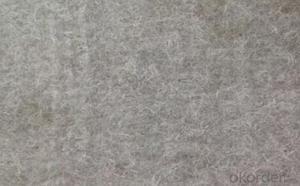

| 3 | Composite fiber fabrics | Material | Polyester Fiber | High strength PET | ||

| Unit area weight g/sq.m | ≥160 | |||||

| Mesh dimension mm | 8×8 | |||||

| Extension strengh kn/m | ≥11 | MD & CD | ||||

| 4 | Filtra layer | Material | Polyester non woven geotextile | |||

| Unit area weight g/sq.m | ≥40 | |||||

| 5 | Grass seeds, Fertilizer | Type | According to actual situation choose 3~5 grass seeds | |||

| Plant height m | 0.1~0.3 | |||||

| 6 | Fiber layer | Material | wood pulp cellulose | |||

| Unit areaweight g/sq.m | ≥15 | |||||

| 7 | flow resistance | ≥4 | not allow appear scour, suction and blanket turn-over etc. damage phenomenon | |||

| M/s | ||||||

| 8 | Anti-UV strengh conservation rate % | 65~80 | 3000hrs Continuously exposure 3000hrs | |||

| 9 | Supporting spare parts | ABS fastening nail | Material | ABS Resin | Fixed between two blankets by length direction | |

| Fiber diameter mm | 35 | |||||

| Nail length mm | 325 | |||||

| Lnail | Material | Steel wire (content 10% zinc-aluminium alloy) | Used to fix single blanket | |||

| Fiber diameter mm | 4 | |||||

| Nail length mm | 200 | |||||

| ABS connecting nail | Material | ABS Resin | Used in the slope between the two blankets ( width direction) | |||

| Nail length mm | 38 | |||||

| Connecting fiber | Material | High strength Polypropylene | Used in the slope between the two blankets ( width direction) | |||

| Length mm | Cut as per request | |||||

APPLICATION:

Generally laid on the river channel, slope protection etc. slope revetment projects, to control the water erosion, soil loss, meantime can reach the effect of slope ecological restoration and landscape greening, making river back to natural.

- Q: Can geogrids be used in underground mining operations?

- Yes, geogrids can be used in underground mining operations. Geogrids are commonly employed in underground mining to provide reinforcement and stabilization to the surrounding rock and soil. They can help prevent slope failures, control ground movement, and enhance the overall safety and efficiency of mining operations.

- Q: How much is the tensile strength of geogrid???????

- Whole plastic stretch type: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: Can geogrids be used for reinforcement in soft soils?

- Yes, geogrids can be used for reinforcement in soft soils. Geogrids are designed to provide stability and improve the load-bearing capacity of soils, including soft soils. They can be installed to distribute and restrain the forces exerted on the soil, preventing excessive settlement and improving overall performance.

- Q: Can geogrids be used in reinforcement of mechanically stabilized slopes?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized slopes. Geogrids are commonly used in slope stabilization projects as they provide high tensile strength and improve the stability and load-bearing capacity of the soil. They help distribute the load and reduce the potential for slope failure, making them an effective solution for reinforcing mechanically stabilized slopes.

- Q: What is the effect of junction strength on geogrid performance?

- The junction strength of a geogrid directly impacts its performance. A higher junction strength enhances the overall stability and load-bearing capacity of the geogrid, allowing it to effectively restrain soil movement and distribute loads. It also improves the geogrid's resistance to deformation, puncture, and tearing. In summary, a strong junction enhances the geogrid's effectiveness and durability in various geotechnical applications.

- Q: Can geogrids be used in ground improvement for industrial facilities?

- Yes, geogrids can be used in ground improvement for industrial facilities. Geogrids are often used to reinforce the soil and improve its stability, which is crucial for supporting heavy structures and equipment in industrial settings. By distributing the load more evenly and reducing settlement, geogrids can enhance the overall performance and longevity of the ground beneath industrial facilities.

- Q: What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of geogrid used can significantly impact the overall cost. Higher quality geogrids may be more expensive but can provide better reinforcement, leading to longer-lasting and more cost-effective structures. Additionally, the design and engineering of the structure play a crucial role. Properly designed structures that consider factors such as soil conditions, loading requirements, and anticipated lifespan can ensure optimal performance and cost-effectiveness. The construction process and techniques employed also influence the cost-effectiveness. Efficient construction methods, skilled labor, and effective project management can minimize costs and maximize the durability and longevity of the geogrid-reinforced structure. Lastly, the maintenance and monitoring of the structure are essential. Regular inspections and timely repairs, if needed, can prevent costly damages and extend the lifespan of the structure, ultimately enhancing its cost-effectiveness.

- Q: Are geogrids suitable for reinforcing landfill liners?

- Yes, geogrids are suitable for reinforcing landfill liners. They are commonly used in landfill engineering to enhance the stability and strength of liners by reducing deformation and improving load distribution. Geogrids also help to prevent soil erosion and provide long-term reinforcement, making them an effective solution for reinforcing landfill liners.

- Q: Construction technology of steel plastic grille

- (6) in the third layer (coarse sand) after rolling, along the line in the longitudinal slope on both sides of the geogrid two, overlapping 0.16m, and connected with the same method, and then start the earthwork construction work, laying geogrid in slope protection, each layer must measure the laying of lines, each side to ensure the slope renovation of geogrid buried in slope soil 0.10m.(7) when the geogrid is filled with two layers of soil, that is to say, the thickness of 0.8m is required to lay a layer of geogrid at the same time on both sides, and so on.(8) the Subgrade after timely slope renovation, and dry rubble slope protection, in addition to each side of the roadbed widening 0.3m, and set aside 1.5% of the settlement.

- Q: What criteria should be used in the construction of Geogrid

- 1, the construction site: requirements compaction flat, horizontal, removal of the protrusion. 2, in the formation of compaction: Geogrid laying site, installation of the grid the main stress direction (longitudinal) should be perpendicular to the axis of the embankment, laying should be smooth, no wrinkles, as far as possible tension. With the plug pin and the earth pressure is fixed, the laying of the grille main stress direction is best long without joint connection between the amplitude and the amplitude of the manual banding lap, lap width not less than 10cm. If the grid is set above two layers, the seam should be staggered. After laying a large area, the overall adjustment of its flatness. When the cover of a layer of soil, not rolling before, should be used manually or machine tensioning grid, the strength should be uniform, so that the grid in the soil for the tension state. 3, the choice of packing: packing should be selected according to the design requirements. Practice has proved that, in addition to frozen soil, swamp soil, domestic waste, chalk, diatomite can be used as filler. However, the mechanical properties of gravelly soil and sandy soil are stable, and the water content is very small. Packing size should not be greater than 15cm, and pay attention to control the packing gradation, to ensure the compaction weight. 4, the packing of the paving and compaction: when the laying of the grid positioning, should be filled in a timely manner, the exposure time shall not exceed 48 hours, can also take the side of the laying of the backfill flow shop. First spread the filler at both ends, the grid will be fixed, and then to the central propulsion. Rolling sequence is the first two sides after the middle. When the roller compaction can not directly contact with the reinforced material, the non compacted reinforcement generally do not allow the vehicle to travel on the above, so as to avoid the dislocation. The degree of compaction is 20-30cm. Pressure...

Send your message to us

Geogrids Fort McMurray Nutrition Geotextile for Greening Various Sizes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords