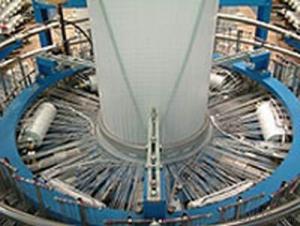

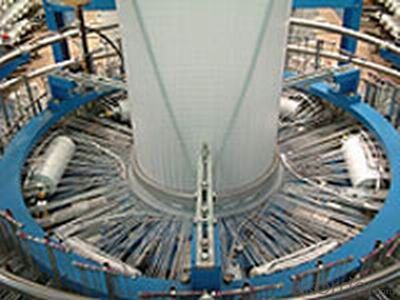

Geocells Suppliers - Circular Knitting Machine for Making Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 5 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

18-feeder computerized artificial fur plain color circular knitting machine can knit the fur&cotton sliver with high quality.

MS18-A 18-feeder computerized artificail fur plain color circular knitting machine can knit the fur&cotton sliver with high quality.

Main specifications and technical features of the MS18-A 18-feeder computerized artificial fur plain color circular knitting machine:

1. With complete up-to-date computer-controlled system, the state of working equipment, automatic fault diagnosis, automatic alarm or other related records could be displayed on the screen.

2. New added technology of broken needle detector improves the quality of jacquard knitting effectively.

3. The head of comb is designed to be more reasonable while the feeding speed and quantity is controlled more effectively, which make it adjustable according to the differences of fabric material, widening its practical scope.

4. The design of adjustable tile can keep those rotating parts such as cylinders working in their best condition and rotating more smoothly and steadily. It can be much easier and more convenient to maintain the machines.

5. Cloth roller adapts magnetic-pull-control system, being the most advanced in the world. It is able to adjust the pull force according to requests, improving the fur weaving quality.

6. Both of ‘Uphil’ angle and ‘Downhil’ angle use advanced “A” and ”B” blocks in order to make working parts such as needle and sinker work with more accuracy and coordination. It is possible to make it a reality to freely change the blocks in the same places with similar blocks.

7. New improved density adjusting equipment provides convenience and accuracy to adjust density of every route, which makes it easy to adjust the machine and simple to operate.

8. The storage of cloth is increased, making it more suitable for production.

9. This product features the advantages of imported machines as respect to appearance and structure and may compare favorably with imported machines.

Cylinder Diameter | 24’’/610mm 27’’/686mm |

Cylinder Grade | E14/1056(24’’) E12/1056(27’’) E14/1176(27’’) |

Feeds Routes | 18 |

Cylinder Speed | 40r/min |

Main Motor Power | 7.5kw |

Weaving Needles Model | 88.82 |

Installation Size(LWH) | 3325mm,2510mm,3425mm |

Woven Geotextiles Data Sheet

Item | Testing Method | Unit | ||

Grad Tensile Strength | ASTM-D 4632 | N | 890 | 1405 |

Grab Elongation | ASTM-D 4632 | % | ≤20 | ≤20 |

Puncture Strength | ASTM-D 4833 | N | 400 | 667 |

CBR Puncture | ASTM-D 6241 | N | 3200 | 4800 |

Mullen Burst | ASTM-D 3786 | kPA | 2578 | 4137 |

Trapezoidal Tear | ASTM-D 4533 | N | 500 | 750 |

Apparent Opening Size | ASTM-D 4751 | mm | 0.425 | 0.425 |

Permittivity | ASTM-D 4491 | Sec-1 | 0.05 | 0.05 |

Water Flow Rate | ASTM-D 4491 | 1/m/m2 | 163 | 163 |

UV Resistance | ASTM-D 4355 | % 500hrs | 70 | 70 |

Roll Width | m | 6 | 6 | |

Roll Length | m |

100 | 100 | |

Mass | GSM | 200 | 300

|

- Q: Can geogrids be used in shoreline erosion control projects?

- Yes, geogrids can be used in shoreline erosion control projects. Geogrids are commonly used in these projects to stabilize the soil and prevent erosion by reinforcing the shoreline and providing structural support. They can effectively control erosion and protect the shoreline from further degradation.

- Q: What are the factors to consider when designing with geogrids for reinforced soil walls?

- When designing with geogrids for reinforced soil walls, there are several important factors to consider. Firstly, the type and strength of the geogrid material is crucial. The geogrid should have sufficient tensile strength and stiffness to effectively reinforce the soil and withstand the loads and stresses imposed on the wall. Secondly, the connection between the geogrid and the soil is critical. Proper anchoring and connection methods must be employed to ensure the geogrid remains securely in place and effectively distributes the loads throughout the reinforced soil structure. Additionally, the design should consider the wall height and slope angle, as these factors impact the stability and performance of the reinforced soil wall. The geogrid spacing and orientation must be determined based on these parameters to achieve the desired stability and load-bearing capacity. Other factors such as soil properties, water drainage, and environmental conditions should also be taken into account to ensure the long-term performance and durability of the reinforced soil wall. Overall, a comprehensive understanding of these factors is essential for successful design and construction with geogrids in reinforced soil walls.

- Q: Are there any specific maintenance requirements for geogrids?

- Yes, geogrids typically have specific maintenance requirements. These requirements may include regular inspection for damage or degradation, cleaning to remove any debris or sediment that may accumulate, and occasional repair or replacement if necessary. It is important to follow the manufacturer's recommendations and guidelines for maintenance to ensure the optimal performance and lifespan of geogrids.

- Q: How much is the tensile strength of Geogrid

- Warp knitting: 15KN--200KN, the highest foreign to 400KN.

- Q: What is the typical weight of a geogrid roll?

- The typical weight of a geogrid roll can vary depending on the specific type and size of the geogrid. However, geogrid rolls generally range in weight from 50 to 500 pounds.

- Q: How do geogrids help in reducing the risk of differential settlement of structures?

- Geogrids help in reducing the risk of differential settlement of structures by providing reinforcement and stability to the soil. They distribute the load over a larger area, preventing localized settlement and ensuring a more uniform settlement across the structure. This helps to maintain the integrity and stability of the structure, reducing the risk of differential settlement and potential damage.

- Q: Can geogrids be used in slope stabilization for railway cuttings?

- Yes, geogrids can be used in slope stabilization for railway cuttings. Geogrids are commonly used to reinforce soil and prevent slope failures or erosion. By installing geogrids within the slope, they help distribute the forces acting on the soil and provide increased stability. This makes geogrids an effective solution for slope stabilization in railway cuttings, where the stability of the slope is crucial for the safety and functionality of the railway infrastructure.

- Q: What are the benefits of using geogrids in soil reinforcement?

- There are several benefits of using geogrids in soil reinforcement. Firstly, geogrids provide increased stability to the soil, preventing erosion and soil movement. They distribute and transfer the load more evenly, reducing the risk of soil settlement and subsidence. Additionally, geogrids improve the bearing capacity of the soil, allowing for the construction of structures on weak or unstable ground. They also enhance the long-term performance of the soil by minimizing the impact of environmental factors like freeze-thaw cycles and moisture changes. Overall, geogrids offer cost-effective and sustainable solutions for soil reinforcement projects.

- Q: Can geogrids be used in temporary construction projects?

- Yes, geogrids can be used in temporary construction projects. Geogrids are often used as reinforcement materials in soil stabilization and retaining walls, providing strength and stability to the construction site. They can be easily installed and removed, making them suitable for temporary applications.

- Q: How do geogrids improve the performance of reinforced soil walls?

- Geogrids improve the performance of reinforced soil walls by providing additional strength and stability to the soil structure. They act as a reinforcement material, distributing the forces exerted on the wall more evenly and preventing the soil from sliding or collapsing. This results in increased load-bearing capacity, reduced settlement, and improved overall stability of the reinforced soil walls.

Send your message to us

Geocells Suppliers - Circular Knitting Machine for Making Woven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 5 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords