SAE 1010 1018 1020 1022 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SAE 1010 1018 1020 1022 Carbon Steel Round Bar

Products Details

Material | AISI 1010, S10C,1.0330,10# | Round bar | Dia(mm) | Max 700 |

Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12000 | |

Heat treatment | Normalized / Annealed / Quenched / tempered | Plate bar | Thickness(mm) | Max 200 |

Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | Max 3000 | |

Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12000 |

Chemical Composition

Standards: ASTM,JIS,GB,EN(DIN,BS,NF)

Grade | C | Si | Mn | Cr | Ni | Cu |

AIAI 1010 | 0.07~0.13 | ≤0.07 | 0.25~0.50 | ≤0.15 | ≤0.30 | ≤0.25 |

Delivery condition

EAF+LF+VD+(ESR), rolled / forged, annealed / Q+T, black/peeled/turned, UT tested

Application

Carbon steel rod applies to chemical industry, shipping industry,manufacturing industry, construction, decorate industry, electric power, pump shafts, sanitary wares, furniture handles, boiler, high temperature resistant,low temperature resistant,corrosion resistant

Sales Information

Material | High Quality Carbon Structural Steel 1010 |

Size | Diameter:10-700mm Length:6000mm-12000mm |

Origin place | Made In China |

Delivery Condition | Hot rolled, cold drawn, forged |

Surface require | Black, grinding, bright, polish |

Heat treatment | Quenched, Tempered, annealed |

Packing | Seaworthy packing ,wooden case ,carton,woven bag or at client's requires |

Delivery time | According to order’s quantity. |

Trade Term | EXW,FOB,CIF |

Payments | T/T or L/C at sight |

Port | China main Port, such as shanghai, Dalian, Shenzhen port. |

MOQ | 30 Metric Ton |

Main Products

AlloyStructural Steel | 5115, 5120, 5130, 5140, 5145, 4118, 4130, 4135, 4140, 4142, 4320, 4340, 4720, 6150, 8620, E9310,etc. |

Carbon Structural Steel | 1010, 1020, 1035, 1045, 1055, 1065,etc. |

Stainless Steel | 201, 202, 301, 302, 304, 305, 316, 316L, 317, 321, 410, 420, 434, 630,etc. |

Tool Steel | H13, D2, 01, D3,H21, P20, M2,etc. |

Bearing Steel | 52100,8620,4320,9310,440C,M50, etc. |

Spring Steel | 5155,5160,6150,9260,SUP6,SUP7,54SiCr6, etc. |

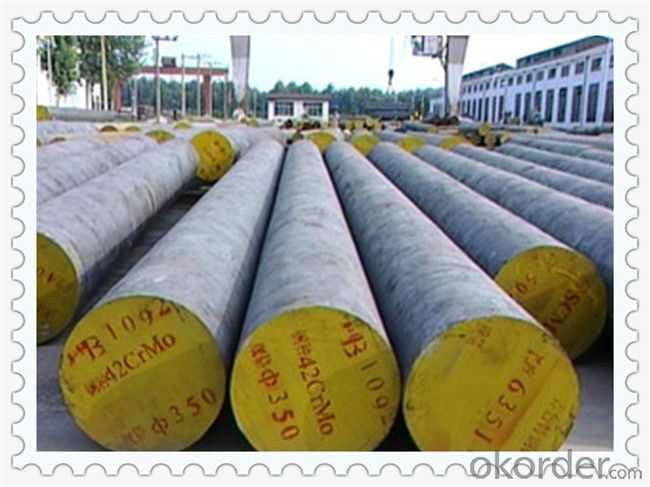

Products Show

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

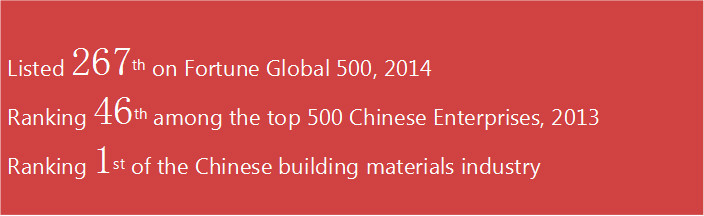

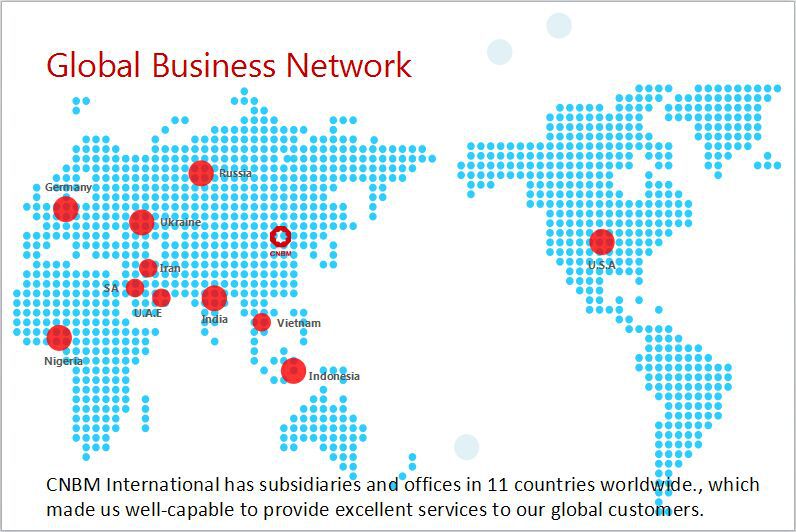

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Are steel round bars suitable for high-stress applications?

- Yes, steel round bars are suitable for high-stress applications. Steel round bars possess high tensile strength, durability, and resistance to deformation, making them ideal for withstanding heavy loads and intense pressure in various industries such as construction, manufacturing, and engineering. The robust nature of steel round bars ensures their suitability for high-stress applications.

- Q: Can steel round bars be galvanized?

- Yes, steel round bars can be galvanized. Galvanizing is a process in which a protective zinc coating is applied to the surface of steel to prevent corrosion. This process can be applied to various steel products, including round bars. Galvanizing steel round bars not only enhances their resistance to corrosion but also improves their durability and longevity. The galvanizing process involves immersing the round bars in a bath of molten zinc, which adheres to the steel and forms a protective layer. This layer acts as a barrier, shielding the steel from moisture, chemicals, and other corrosive elements. As a result, galvanized steel round bars are commonly used in outdoor applications, such as construction, fencing, and marine environments, where they are exposed to harsh conditions.

- Q: What are the different types of steel round bars used in the manufacturing of shafts?

- When manufacturing shafts, various types of steel round bars are commonly used. The selection of the steel round bar depends on the specific application and requirements of the shaft. Here are some of the frequently utilized types: 1. Carbon Steel Round Bars: These round bars are the most commonly used in shaft manufacturing. Carbon steel provides good strength and toughness, making it suitable for a range of shaft applications. 2. Alloy Steel Round Bars: By adding elements like chromium, nickel, or molybdenum to carbon steel, alloy steel round bars are created. This enhances the strength, hardness, and wear resistance of the shaft, making it appropriate for demanding applications. 3. Stainless Steel Round Bars: Stainless steel is highly resistant to corrosion and offers excellent mechanical properties. It is commonly used in shafts that require resistance to corrosion, high temperatures, or harsh environments. 4. Tool Steel Round Bars: Tool steel round bars are renowned for their exceptional hardness, toughness, and wear resistance. They are used in shafts for cutting tools, molds, and dies that necessitate high performance and durability. 5. High-Speed Steel Round Bars: Primarily used in shafts for cutting tools such as drills, mills, and taps, high-speed steel round bars possess excellent heat resistance and can withstand high cutting speeds without losing their hardness. 6. Mild Steel Round Bars: Mild steel round bars are low carbon steel bars that offer good weldability and machinability. They are commonly used in shafts for less demanding applications that do not require high strength or hardness. Considering the specific requirements, such as strength, hardness, corrosion resistance, and temperature resistance, is crucial when choosing the appropriate type of steel round bar for manufacturing shafts.

- Q: What are the different surface coatings available for steel round bars?

- Steel round bars have several surface coatings available, each with their own unique benefits and uses. Some of the most commonly used surface coatings include: 1. Galvanized Coating: By hot-dip galvanizing, a layer of zinc is applied to the surface of the steel round bar. This zinc coating provides excellent corrosion resistance, protecting the steel from rust and other forms of degradation. Galvanized coatings are frequently used in outdoor and high-humidity environments. 2. Epoxy Coating: Epoxy coatings are either applied as a powder or liquid and then cured through a chemical reaction. They offer outstanding chemical resistance, durability, and protection against corrosion. Epoxy coatings are often employed in industrial and marine applications where harsh chemicals or exposure to saltwater are a concern. 3. Chrome Plating: The surface of the steel round bar is electroplated with a layer of chromium in chrome plating. This process provides high corrosion resistance, as well as excellent hardness and wear resistance. It is commonly utilized in applications that require aesthetic appeal and enhanced durability, such as automotive parts and decorative fixtures. 4. Powder Coating: Powder coating is a dry finishing process in which a powdered polymer is applied to the surface of the steel round bar and then heat-cured. This creates a durable and decorative finish that is resistant to chipping, scratching, and fading. Powder coatings are available in a wide range of colors and textures, making them popular for architectural and decorative purposes. 5. Black Oxide Coating: Black oxide is a conversion coating that is formed through a chemical reaction with the steel surface. It provides a black, decorative finish while also offering mild corrosion resistance. Black oxide coatings are widely used in applications where an aesthetic appearance is desired, such as firearms and hardware. These examples demonstrate the variety of surface coatings available for steel round bars. The choice of coating depends on specific application requirements, including the desired level of corrosion resistance, durability, and aesthetic appeal.

- Q: How do you measure the diameter tolerance of a steel round bar?

- The diameter tolerance of a steel round bar can be measured using a caliper or micrometer tool. The tool is used to measure the diameter of the bar at multiple points along its length. The measurements are then compared to the specified diameter tolerance range to determine if the bar falls within the acceptable limits.

- Q: What are the common industries that use steel round bars?

- Steel round bars are widely used in various industries due to their strength, durability, and versatility. Some of the common industries that heavily rely on steel round bars include construction, manufacturing, automotive, aerospace, energy, and oil and gas. In the construction industry, steel round bars are commonly used in the creation of structural frameworks, such as beams, columns, and trusses. They provide the necessary support and stability required for buildings, bridges, and other infrastructures. Additionally, steel round bars are utilized in reinforcement applications, such as concrete reinforcement bars (rebars), ensuring the structural integrity of various construction projects. The manufacturing industry also extensively utilizes steel round bars for the production of machinery, equipment, and tools. These round bars are often machined, forged, or heat-treated to create components like shafts, gears, fasteners, and bearings. Due to their high tensile strength and resistance to wear and tear, steel round bars are ideal for withstanding heavy loads and harsh operating conditions. In the automotive sector, steel round bars are employed in the manufacturing of various vehicle components, including axles, crankshafts, camshafts, and suspension systems. The use of steel round bars in these critical parts ensures the necessary strength and durability required for safe and reliable transportation. The aerospace industry heavily relies on steel round bars for the production of aircraft components. From landing gear to engine parts and structural elements, steel round bars are essential in ensuring the safety and performance of aircraft. The high strength-to-weight ratio of steel makes it an ideal material for aerospace applications, as it allows for lighter aircraft without compromising strength. Furthermore, the energy industry, including power generation and transmission, utilizes steel round bars in the construction of turbines, generators, and transmission towers. The robustness and corrosion resistance of steel make it suitable for withstanding extreme temperatures and harsh environments. Lastly, the oil and gas industry extensively uses steel round bars for drilling equipment, pipe fittings, valves, and other critical components. These round bars are required to withstand high-pressure and corrosive environments, making them essential for oil and gas exploration, extraction, and transportation. In conclusion, steel round bars find application in a wide range of industries, including construction, manufacturing, automotive, aerospace, energy, and oil and gas. Their strength, durability, and versatility make them a preferred choice for various applications, ensuring the safety, reliability, and efficiency of numerous industrial processes.

- Q: Can steel round bars be used for making bicycle frames or handlebars?

- Yes, steel round bars can be used for making bicycle frames or handlebars. Steel is a commonly used material in bicycle manufacturing due to its strength, durability, and affordability. Round bars made of steel provide excellent rigidity and stability, which are essential for ensuring the structural integrity of a bicycle frame or handlebars. Additionally, steel has a high tensile strength, allowing it to withstand the stresses and strains experienced during cycling. It is worth noting that different types of steel, such as chromoly steel, may be preferred for bicycle frames and handlebars as they offer specific advantages such as improved strength-to-weight ratio. However, in general, steel round bars are a suitable choice for constructing bicycle frames and handlebars.

- Q: Can steel round bars be used for making hydraulic systems?

- Steel round bars can indeed be used for making hydraulic systems. Steel is a durable and strong material that can withstand high pressure and extreme conditions, making it suitable for hydraulic applications. Steel round bars can be machined and shaped into various components such as cylinders, pistons, and shafts, which are essential parts of hydraulic systems. Additionally, steel is resistant to corrosion, which is crucial for hydraulic systems that often come into contact with fluids. However, it is important to ensure that the steel round bars used for hydraulic systems meet the necessary specifications and requirements, such as hardness, tensile strength, and dimensional accuracy, to ensure optimal performance and reliability.

- Q: What are the different types of steel round bar surface finishes used in the construction industry?

- Steel round bars are widely used in the construction industry due to their strength and durability. To meet specific requirements and enhance performance, these bars undergo various surface finishes. Some common surface finishes used in construction include: 1. Hot Rolled Finish: The most commonly used finish involves heating the steel bar above its recrystallization temperature and rolling it through rollers. This process creates a rough and scale-covered surface. 2. Cold Drawn Finish: This process involves drawing the steel bar through dies to reduce its diameter and increase its length. Cold drawing produces a smooth and shiny surface, ideal for applications where aesthetics and precision are important. 3. Peeled and Polished Finish: This finish includes removing the outer layer of the steel bar through peeling and polishing it to achieve a smooth and mirror-like surface. It is often used in applications that require high visual appeal, such as architectural structures or decorative elements. 4. Ground Finish: Grinding is used to achieve a smooth and uniform surface finish on steel round bars. The process removes imperfections and unevenness, resulting in a precise and polished surface. Ground finishes are commonly used in applications that require tight tolerances, such as machinery or automotive components. 5. Coated Finish: Steel round bars can be coated with various materials, such as galvanized, epoxy, or powder coatings, to enhance corrosion resistance and provide additional properties. These coatings not only protect the steel from environmental factors but also improve its aesthetic appeal. Each surface finish offers unique advantages and is chosen based on specific project requirements. Whether it's for aesthetics, corrosion resistance, or tolerances, selecting the right surface finish is crucial to ensure optimal performance of steel round bars in their intended applications.

- Q: What are the advantages of using nickel-chromium alloy steel round bars?

- Using nickel-chromium alloy steel round bars in various applications offers several benefits. Firstly, these round bars possess outstanding corrosion resistance properties. The inclusion of nickel and chromium elements in the alloy enhances its ability to withstand corrosion from moisture, chemicals, and oxidation, making it suitable for use in challenging environments like marine applications, chemical processing plants, and oil refineries. Secondly, these round bars exhibit high temperature resistance. The combination of nickel and chromium in the alloy allows it to endure elevated temperatures without compromising its structural integrity. This makes them ideal for use in heat exchangers, furnaces, and other high-temperature applications. Furthermore, these round bars boast exceptional mechanical properties. They demonstrate excellent strength, toughness, and wear resistance, making them ideal for applications that require high load-bearing capabilities. Additionally, they exhibit good ductility, enabling easy machining and fabrication. Additionally, these round bars possess good electrical conductivity, making them suitable for electrical and electronic applications where conductivity is crucial, such as in the manufacturing of resistors, heating elements, and electrical connectors. Lastly, these round bars are readily available and cost-effective. Being a widely used material in various industries, they are easily accessible and can be obtained at competitive prices. In conclusion, the advantages of utilizing nickel-chromium alloy steel round bars encompass excellent corrosion resistance, high-temperature resistance, superior mechanical properties, good electrical conductivity, and cost-effectiveness. These characteristics make them the preferred choice for a wide range of applications in industries such as construction, automotive, aerospace, and electrical engineering.

Send your message to us

SAE 1010 1018 1020 1022 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords